Rubber compound refers to a specific mixture of raw rubber and additives designed to achieve desired physical properties, while rubber blend is the combination of two or more different types of rubber polymers to enhance performance characteristics. Understanding the difference between rubber compound and rubber blend helps you select the right material for your application, optimizing durability and flexibility.

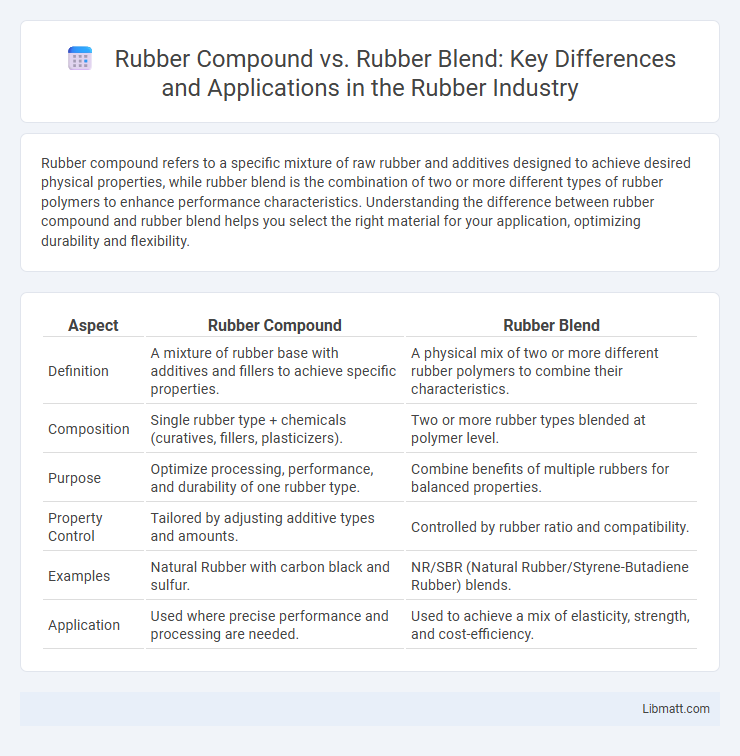

Table of Comparison

| Aspect | Rubber Compound | Rubber Blend |

|---|---|---|

| Definition | A mixture of rubber base with additives and fillers to achieve specific properties. | A physical mix of two or more different rubber polymers to combine their characteristics. |

| Composition | Single rubber type + chemicals (curatives, fillers, plasticizers). | Two or more rubber types blended at polymer level. |

| Purpose | Optimize processing, performance, and durability of one rubber type. | Combine benefits of multiple rubbers for balanced properties. |

| Property Control | Tailored by adjusting additive types and amounts. | Controlled by rubber ratio and compatibility. |

| Examples | Natural Rubber with carbon black and sulfur. | NR/SBR (Natural Rubber/Styrene-Butadiene Rubber) blends. |

| Application | Used where precise performance and processing are needed. | Used to achieve a mix of elasticity, strength, and cost-efficiency. |

Introduction to Rubber Compound and Rubber Blend

Rubber compound consists of natural or synthetic rubber combined with fillers, additives, and chemicals to achieve specific performance properties such as elasticity, durability, and heat resistance. Rubber blend involves mixing two or more distinct types of rubber to enhance characteristics like strength, flexibility, and chemical resistance that single compounds cannot achieve alone. Understanding the differences between rubber compound and rubber blend is crucial for selecting the right material in applications ranging from automotive tires to industrial seals.

Key Differences Between Rubber Compound and Rubber Blend

Rubber compound refers to a carefully formulated mixture of base rubber, fillers, curing agents, and additives designed to achieve specific mechanical and chemical properties for targeted applications. Rubber blend, in contrast, involves physically mixing two or more distinct rubber types to combine their inherent characteristics without significant chemical alteration. Key differences include the precision of property customization in compounds versus the synergistic property enhancement aimed for in blends.

Composition and Ingredients

Rubber compound consists of a single type of elastomer combined with various fillers, chemicals, and additives tailored to enhance specific physical properties for targeted applications. Rubber blend, on the other hand, involves mixing two or more different elastomers to harness a combination of their inherent characteristics, optimizing performance through synergistic effects. Understanding the composition and ingredients helps you select the right material to meet durability, flexibility, and resistance requirements in your products.

Manufacturing Processes

Rubber compound manufacturing involves blending raw polymers with additives such as fillers, plasticizers, and curing agents to create a uniform material ready for shaping and vulcanization. In contrast, rubber blend production combines two or more different rubber types physically without fully mixing the components at the molecular level, preserving distinct properties within the final product. Understanding these manufacturing processes enables you to select the suitable material for applications requiring specific mechanical and chemical performance.

Mechanical and Physical Properties

Rubber compounds exhibit tailored mechanical and physical properties through the precise mixing of polymers, fillers, and additives, resulting in enhanced strength, elasticity, and abrasion resistance suited for specific applications. Rubber blends combine two or more different rubbers to balance properties like tensile strength, flexibility, and chemical resistance, offering improved overall performance in diverse environments. Your choice between a rubber compound and blend depends on the required durability, flexibility, and resistance characteristics for optimal product functionality.

Performance in Different Applications

Rubber compounds are specifically engineered mixtures of polymers, fillers, and additives designed to achieve targeted mechanical and chemical properties, enabling superior performance in applications like automotive tires and industrial seals. Rubber blends combine different types of rubber polymers to balance flexibility, durability, and resistance, making them ideal for diverse uses such as footwear soles and vibration dampening components. Your choice between a rubber compound and a rubber blend depends on the performance requirements, including wear resistance, elasticity, and environmental stability needed for the specific application.

Cost Comparison and Economic Considerations

Rubber compounds typically involve a single base rubber mixed with various additives, often resulting in lower material costs compared to rubber blends, which combine two or more different rubbers to achieve specific performance characteristics. Your choice between rubber compound and rubber blend significantly impacts production expenses, with blends usually incurring higher processing and formulation costs due to their complexity. Evaluating cost-effectiveness requires balancing initial material prices against the long-term benefits of enhanced durability and performance offered by rubber blends in specialized applications.

Environmental Impact and Sustainability

Rubber compounds typically involve specific additives and fillers tailored for performance, which can increase the environmental footprint due to chemical processing and non-biodegradable components. Rubber blends mix different types of rubber to optimize properties, often allowing for more recycled content and reduced waste, enhancing sustainability. Choosing blends with natural or recycled rubbers lowers carbon emissions and landfill impact compared to single-compound formulations.

Common Industries and Use Cases

Rubber compounds are extensively utilized in the automotive and manufacturing industries due to their tailored properties for specific performance needs such as durability and flexibility. Rubber blends find common applications in footwear and sports equipment, where combining different rubbers enhances elasticity and wear resistance. Your choice between compound and blend depends on the desired balance of physical characteristics for industry-specific applications.

Choosing Between Rubber Compound and Rubber Blend

Choosing between rubber compound and rubber blend depends on the desired material properties and application requirements. Rubber compounds are formulated by combining raw rubber with fillers, additives, and curing agents to achieve specific mechanical strength, elasticity, and chemical resistance. Rubber blends mix two or more types of elastomers to balance characteristics like flexibility, durability, and thermal stability for specialized industrial uses.

Rubber Compound vs Rubber Blend Infographic

libmatt.com

libmatt.com