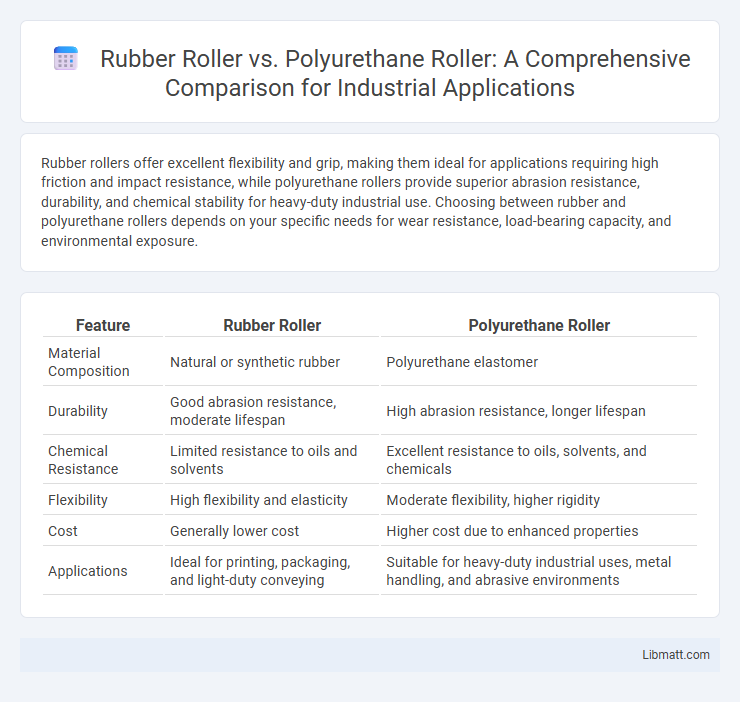

Rubber rollers offer excellent flexibility and grip, making them ideal for applications requiring high friction and impact resistance, while polyurethane rollers provide superior abrasion resistance, durability, and chemical stability for heavy-duty industrial use. Choosing between rubber and polyurethane rollers depends on your specific needs for wear resistance, load-bearing capacity, and environmental exposure.

Table of Comparison

| Feature | Rubber Roller | Polyurethane Roller |

|---|---|---|

| Material Composition | Natural or synthetic rubber | Polyurethane elastomer |

| Durability | Good abrasion resistance, moderate lifespan | High abrasion resistance, longer lifespan |

| Chemical Resistance | Limited resistance to oils and solvents | Excellent resistance to oils, solvents, and chemicals |

| Flexibility | High flexibility and elasticity | Moderate flexibility, higher rigidity |

| Cost | Generally lower cost | Higher cost due to enhanced properties |

| Applications | Ideal for printing, packaging, and light-duty conveying | Suitable for heavy-duty industrial uses, metal handling, and abrasive environments |

Introduction to Rubber and Polyurethane Rollers

Rubber rollers offer excellent elasticity, abrasion resistance, and grip, making them ideal for applications involving high friction and shock absorption. Polyurethane rollers provide superior durability, chemical resistance, and load-bearing capacity, excelling in environments requiring extended wear and exposure to oils or solvents. Your choice between rubber and polyurethane rollers depends on the specific operational demands, such as flexibility versus toughness and resistance to environmental factors.

Material Composition: Rubber vs Polyurethane

Rubber rollers are made from natural or synthetic rubber, offering excellent elasticity, high grip, and resistance to abrasion and impact, making them suitable for applications requiring flexibility and durability. Polyurethane rollers consist of a polymer composed of organic units linked by carbamate (urethane) bonds, providing superior wear resistance, higher load-bearing capacity, and better chemical resistance compared to rubber. The material composition directly influences performance characteristics, with rubber excelling in flexibility and grip, while polyurethane excels in toughness and resistance to harsh environments.

Durability and Wear Resistance Comparison

Rubber rollers offer excellent flexibility and grip but tend to wear faster under heavy abrasion compared to polyurethane rollers, which provide superior durability and wear resistance in industrial applications. Polyurethane rollers maintain their shape and performance longer under harsh conditions, resisting cuts, chemicals, and impact damage better than rubber. Choosing polyurethane rollers for your machinery can significantly extend operational life and reduce maintenance costs.

Performance in Various Industrial Applications

Rubber rollers offer excellent flexibility and high grip, making them suitable for applications involving delicate materials or variable surface textures, such as printing and packaging industries. Polyurethane rollers provide superior abrasion resistance and load-bearing capacity, ideal for heavy-duty processes like steel processing and conveyor systems. Understanding the specific demands of your industrial application helps determine whether rubber or polyurethane rollers will enhance performance and longevity.

Load Capacity and Flexibility Differences

Rubber rollers offer greater flexibility due to their softer composition, allowing better shock absorption and adaptability to irregular surfaces, but they generally support lower load capacities compared to polyurethane rollers. Polyurethane rollers possess higher load-bearing capabilities and superior wear resistance, making them ideal for heavy-duty applications requiring durability and consistent performance. Choosing the right roller affects your equipment's efficiency, balancing flexibility needs with load capacity requirements.

Chemical and Temperature Resistance

Rubber rollers offer excellent chemical resistance to acids and alkalis but may degrade when exposed to strong solvents or high temperatures above 200degF (93degC). Polyurethane rollers provide superior resistance to oils, solvents, and abrasion, maintaining structural integrity in temperatures up to 250degF (121degC). Choosing the right roller depends on the chemical exposure and temperature conditions of your application to ensure durability and performance.

Maintenance and Lifespan Considerations

Rubber rollers typically require more frequent maintenance due to their susceptibility to wear, cracking, and chemical degradation, while polyurethane rollers offer enhanced durability and resistance to abrasion, extending their lifespan significantly. Your choice between rubber and polyurethane rollers should consider the operational environment, as polyurethane rollers maintain performance under harsh conditions, reducing downtime and replacement frequency. Proper maintenance routines tailored to the roller material can optimize performance and maximize the lifespan of your equipment.

Cost Analysis: Rubber vs Polyurethane Rollers

Rubber rollers generally offer a lower initial cost compared to polyurethane rollers, making them a cost-effective choice for short-term applications. Polyurethane rollers, although more expensive upfront, provide superior durability and resistance to abrasion, chemicals, and impact, reducing long-term maintenance and replacement expenses. Evaluating total cost of ownership, polyurethane rollers often deliver better value in demanding industrial settings due to their extended lifespan and lower downtime costs.

Environmental Impact and Sustainability

Rubber rollers typically have a higher environmental impact due to their reliance on natural latex or synthetic rubber derived from petroleum, which may involve non-renewable resources and slower biodegradability. Polyurethane rollers, made from versatile polymers, often offer improved sustainability through enhanced durability and longer service life, reducing the frequency of replacements and waste. Manufacturing processes for polyurethane can be optimized for lower emissions and recyclability, making them a more eco-friendly choice in many industrial applications.

Choosing the Right Roller for Your Application

Selecting the right roller between rubber and polyurethane depends on specific application needs such as load capacity, wear resistance, and chemical exposure. Rubber rollers offer superior grip and shock absorption, ideal for delicate materials and light-duty tasks, while polyurethane rollers provide higher durability, abrasion resistance, and chemical tolerance, suited for heavy-duty industrial environments. Evaluating factors like operational conditions, surface texture, and maintenance requirements ensures optimal performance and longevity for your roller choice.

Rubber Roller vs Polyurethane Roller Infographic

libmatt.com

libmatt.com