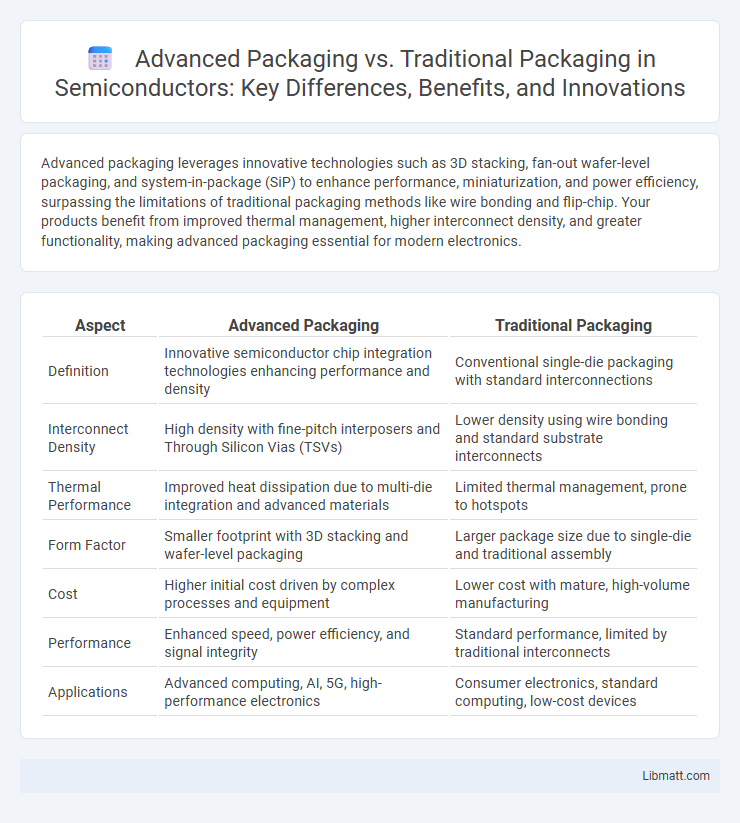

Advanced packaging leverages innovative technologies such as 3D stacking, fan-out wafer-level packaging, and system-in-package (SiP) to enhance performance, miniaturization, and power efficiency, surpassing the limitations of traditional packaging methods like wire bonding and flip-chip. Your products benefit from improved thermal management, higher interconnect density, and greater functionality, making advanced packaging essential for modern electronics.

Table of Comparison

| Aspect | Advanced Packaging | Traditional Packaging |

|---|---|---|

| Definition | Innovative semiconductor chip integration technologies enhancing performance and density | Conventional single-die packaging with standard interconnections |

| Interconnect Density | High density with fine-pitch interposers and Through Silicon Vias (TSVs) | Lower density using wire bonding and standard substrate interconnects |

| Thermal Performance | Improved heat dissipation due to multi-die integration and advanced materials | Limited thermal management, prone to hotspots |

| Form Factor | Smaller footprint with 3D stacking and wafer-level packaging | Larger package size due to single-die and traditional assembly |

| Cost | Higher initial cost driven by complex processes and equipment | Lower cost with mature, high-volume manufacturing |

| Performance | Enhanced speed, power efficiency, and signal integrity | Standard performance, limited by traditional interconnects |

| Applications | Advanced computing, AI, 5G, high-performance electronics | Consumer electronics, standard computing, low-cost devices |

Introduction to Advanced and Traditional Packaging

Advanced packaging technologies, such as 2.5D and 3D integration, offer enhanced performance, miniaturization, and power efficiency compared to traditional packaging methods like wire bonding and ball grid arrays. Traditional packaging primarily focuses on simple chip encapsulation and interconnections, which limit signal speed and thermal dissipation. Advanced packaging utilizes innovative materials and architectures to improve electrical performance, reduce latency, and support higher transistor densities in modern semiconductor devices.

Key Differences Between Advanced and Traditional Packaging

Advanced packaging employs techniques like wafer-level packaging and 3D stacking to enhance performance and reduce size, whereas traditional packaging relies on older methods such as wire bonding and lead frames. Advanced packaging supports higher input/output (I/O) density, improved thermal management, and better electrical performance compared to the limited scalability and increased parasitic effects in traditional packaging. These differences make advanced packaging crucial for applications in AI, 5G, and high-performance computing where speed, power efficiency, and miniaturization are essential.

Materials Used in Advanced vs Traditional Packaging

Advanced packaging utilizes high-performance materials such as silicon interposers, organic substrates, and fan-out wafer-level packaging (FOWLP) materials, offering superior electrical and thermal conductivity. Traditional packaging typically relies on simpler materials like ceramic, plastic, and lead frames, which provide adequate insulation but limited integration density and heat dissipation. The shift to advanced materials enhances device miniaturization, signal integrity, and overall system performance compared to conventional packaging solutions.

Technological Innovations in Advanced Packaging

Technological innovations in advanced packaging include techniques such as 3D stacking, silicon interposers, and wafer-level packaging, which enable higher performance and greater component density compared to traditional packaging. These advancements improve electrical performance, thermal management, and signal integrity, essential for modern high-speed and miniaturized devices. You gain enhanced reliability and efficiency in your electronic products by leveraging these cutting-edge packaging solutions.

Cost Comparison: Advanced vs Traditional Packaging

Advanced packaging often involves higher initial costs due to complex materials and processes like wafer-level packaging and 3D stacking, yet offers cost efficiencies in device miniaturization and enhanced performance. Traditional packaging incurs lower upfront expenses with standard methods such as wire bonding and flip-chip, but may lead to higher expenses over time due to limited scalability and reduced thermal management. The total cost of ownership favors advanced packaging for high-performance applications despite its premium, while traditional packaging remains cost-effective for low to mid-range semiconductor products.

Performance and Efficiency Analysis

Advanced packaging technologies enhance performance by enabling higher transistor density and improved thermal management, resulting in faster processing speeds and reduced power consumption compared to traditional packaging. Efficiency gains are realized through 3D stacking and heterogeneous integration, which minimize signal delays and optimize space utilization within electronic devices. Traditional packaging methods, while cost-effective and mature, often face limitations in scaling and heat dissipation, impacting overall device efficiency at advanced nodes.

Sustainability and Environmental Impact

Advanced packaging techniques reduce material waste and enhance recyclability, significantly lowering the environmental footprint compared to traditional packaging. Your choice of advanced packaging supports sustainability by minimizing carbon emissions and promoting resource efficiency through innovative materials and designs. Traditional packaging often relies on non-recyclable plastics, contributing to landfill buildup and increased environmental degradation.

Applications in Various Industries

Advanced packaging technologies such as system-in-package (SiP) and 3D packaging are revolutionizing applications across industries like consumer electronics, automotive, healthcare, and telecommunications by enabling smaller, more efficient, and higher-performance devices. Traditional packaging, while reliable for simpler, less demanding applications, often falls short in meeting the miniaturization and heat dissipation needs required by modern high-speed processors and IoT devices. Your choice between advanced and traditional packaging significantly impacts product performance, durability, and integration capabilities in specific industrial applications.

Future Trends in Packaging Technologies

Future trends in packaging technologies emphasize the shift from Traditional Packaging to Advanced Packaging, incorporating smart materials, nanotechnology, and eco-friendly solutions to enhance product protection and consumer interaction. Advanced Packaging integrates sensors and IoT capabilities to provide real-time tracking and ensure product authenticity, while Traditional Packaging primarily relies on physical barriers and static designs. Your business can benefit from adopting these innovations to meet sustainability goals and improve customer engagement in a competitive market.

Choosing the Right Packaging Solution

Selecting the right packaging solution involves comparing advanced packaging technologies such as 3D IC integration, fan-out wafer-level packaging, and system-in-package (SiP) with traditional methods like wire bonding and chip-on-board (COB). Advanced packaging offers improved performance, higher density, and better thermal management, making it ideal for high-speed applications, while traditional packaging remains cost-effective for simpler devices with lower power requirements. Evaluating factors including device complexity, production volume, cost constraints, and performance needs ensures the optimal packaging choice for enhanced reliability and efficiency.

Advanced Packaging vs Traditional Packaging Infographic

libmatt.com

libmatt.com