Hard bake uses high heat for a longer period to create a fully cured, durable photoresist layer ideal for final processing, while soft bake employs lower temperatures briefly to gently remove solvents and improve adhesion without fully curing the resist. Your choice between hard bake and soft bake impacts the quality and performance of microfabrication and photolithography processes.

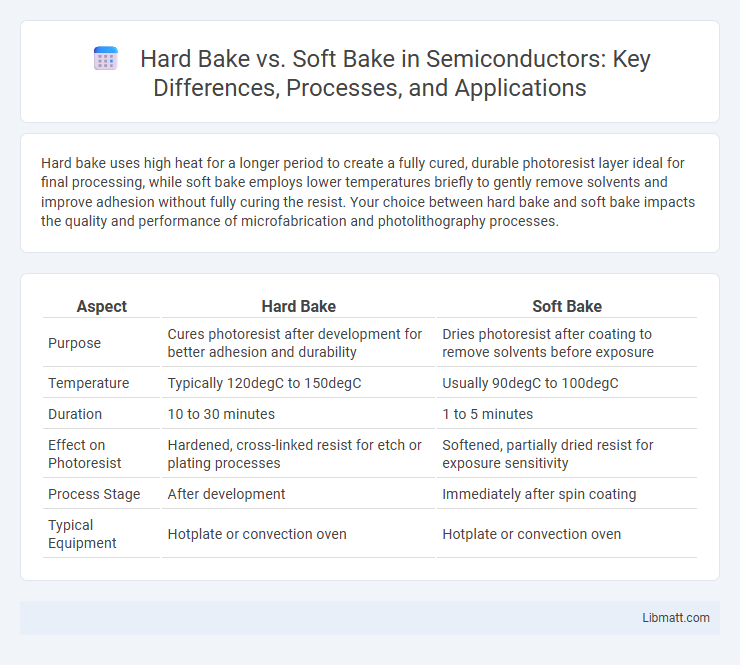

Table of Comparison

| Aspect | Hard Bake | Soft Bake |

|---|---|---|

| Purpose | Cures photoresist after development for better adhesion and durability | Dries photoresist after coating to remove solvents before exposure |

| Temperature | Typically 120degC to 150degC | Usually 90degC to 100degC |

| Duration | 10 to 30 minutes | 1 to 5 minutes |

| Effect on Photoresist | Hardened, cross-linked resist for etch or plating processes | Softened, partially dried resist for exposure sensitivity |

| Process Stage | After development | Immediately after spin coating |

| Typical Equipment | Hotplate or convection oven | Hotplate or convection oven |

Introduction to Hard Bake and Soft Bake

Hard Bake and Soft Bake are essential processes in photolithography used to cure photoresist layers during semiconductor manufacturing. Soft Bake gently removes solvents from the photoresist to improve adhesion and film stability before exposure, typically performed at lower temperatures around 90-100degC. Hard Bake follows exposure and development to solidify the pattern permanently, involving higher temperatures near 120-150degC to enhance the photoresist's etch resistance and durability for subsequent processing steps.

Understanding the Photolithography Process

Hard bake and soft bake are crucial steps in the photolithography process, where soft bake removes solvents from the photoresist to improve adhesion and reduce defects during exposure. Hard bake follows to further cure the photoresist, enhancing its durability and resistance to etching in semiconductor manufacturing. Understanding these temperature-controlled baking stages optimizes your photolithography results for precise pattern transfer on silicon wafers.

What is Soft Bake?

Soft bake is a critical process in photolithography where a photoresist-coated substrate is gently heated to evaporate solvents and improve film adhesion without fully curing the resist. This step typically occurs at temperatures between 90degC and 110degC for a duration of 30 to 120 seconds, depending on the resist type and substrate. Proper soft bake ensures uniform photoresist thickness, enhanced pattern resolution, and reduces defects during subsequent exposure and development stages.

What is Hard Bake?

Hard bake is a post-exposure baking process used in photolithography to improve the chemical and mechanical stability of photoresist patterns by driving out residual solvents and enhancing adhesion to the substrate. The process typically involves heating the wafer at higher temperatures, around 150-200degC, for a longer duration compared to soft bake, which helps harden the photoresist and prevents pattern distortion during subsequent etching or implant steps. Hard bake is essential for improving the durability of resist profiles in microfabrication and semiconductor manufacturing.

Key Differences Between Hard Bake and Soft Bake

Hard bake involves longer, higher temperature curing processes that fully solidify photoresist layers, enhancing adhesion and durability for microfabrication. Soft bake is a preliminary, lower temperature step designed to evaporate solvents and improve photoresist uniformity without full polymerization. The key differences lie in temperature profiles, duration, and their impact on photoresist properties and subsequent lithographic performance.

Purposes and Applications of Soft Bake

Soft bake primarily serves to gently remove solvents from photoresist layers, stabilizing the material before exposure steps in photolithography. This process ensures optimal adhesion and uniformity, critical for precise pattern transfer in semiconductor manufacturing and printed circuit board production. Your fabrication yields improve as soft bake minimizes defects caused by solvent residues, enhancing overall process reliability.

Purposes and Applications of Hard Bake

Hard bake serves to permanently cure photoresist layers, enhancing their chemical resistance and mechanical stability during semiconductor fabrication. It is primarily used after development to solidify patterns that must withstand aggressive etching, plating, or ion implantation processes. This bake ensures high-fidelity pattern transfer in applications requiring durable photoresist films, such as microelectromechanical systems (MEMS) and advanced lithography steps.

Effects on Photoresist Performance

Hard bake enhances photoresist durability by improving adhesion and increasing resistance to etching and chemical solvents, making it ideal for long-term process stability. Soft bake primarily removes solvents and reduces film stress, which ensures uniform photoresist thickness and better pattern resolution during exposure. Your choice between hard bake and soft bake directly impacts the quality of microfabrication, with hard bake offering stronger performance for demanding applications.

Common Problems and Solutions

Hard bake often causes film cracking due to excessive heat, so lowering the temperature or baking time can prevent this issue. Soft bake commonly leads to incomplete solvent evaporation, resulting in film bubbling, which can be resolved by extending the baking duration or adjusting the temperature. You can improve coating quality by selecting the appropriate bake method and carefully controlling the process parameters to address these common problems.

Choosing the Right Bake Process for Your Application

Selecting between hard bake and soft bake processes depends on the specific application requirements such as thermal resistance, adhesion strength, and curing time. Hard bake offers higher durability and chemical resistance, ideal for printed circuit boards and applications requiring long-term stability. Soft bake provides faster solvent removal and is suitable for delicate substrates or temporary layers where moderate hardness is sufficient.

Hard Bake vs Soft Bake Infographic

libmatt.com

libmatt.com