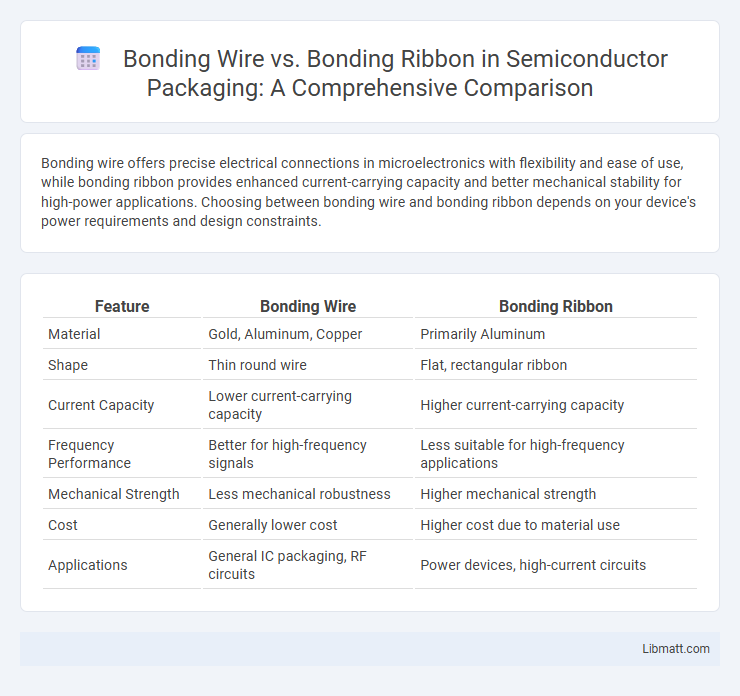

Bonding wire offers precise electrical connections in microelectronics with flexibility and ease of use, while bonding ribbon provides enhanced current-carrying capacity and better mechanical stability for high-power applications. Choosing between bonding wire and bonding ribbon depends on your device's power requirements and design constraints.

Table of Comparison

| Feature | Bonding Wire | Bonding Ribbon |

|---|---|---|

| Material | Gold, Aluminum, Copper | Primarily Aluminum |

| Shape | Thin round wire | Flat, rectangular ribbon |

| Current Capacity | Lower current-carrying capacity | Higher current-carrying capacity |

| Frequency Performance | Better for high-frequency signals | Less suitable for high-frequency applications |

| Mechanical Strength | Less mechanical robustness | Higher mechanical strength |

| Cost | Generally lower cost | Higher cost due to material use |

| Applications | General IC packaging, RF circuits | Power devices, high-current circuits |

Introduction to Bonding Wire and Bonding Ribbon

Bonding wire and bonding ribbon are essential materials used in semiconductor packaging to create reliable electrical connections between integrated circuits and external components. Bonding wire, typically made of gold, aluminum, or copper, features a thin, flexible strand ideal for precise, high-density connections. Bonding ribbon, a flat, wider conductor, offers lower resistance and higher current capacity, making it suitable for applications requiring enhanced electrical performance and mechanical strength.

Key Differences Between Bonding Wire and Bonding Ribbon

Bonding wire and bonding ribbon differ primarily in shape and current-carrying capacity, with bonding wire being thin and round, ideal for high-frequency and precision applications, while bonding ribbon is flat and wider, offering lower resistance and better heat dissipation for high-current circuits. Bonding wire excels in flexibility and fine-pitch connections, whereas bonding ribbon provides superior mechanical strength and is preferred for power electronics where robust connections are critical. Material composition typically involves gold, aluminum, or copper for both, but ribbons often use thicker cross-sections to handle greater electrical loads efficiently.

Material Composition and Characteristics

Bonding wire is typically made from gold, copper, or aluminum, each offering distinct electrical conductivity and mechanical flexibility suited for fine-pitch semiconductor applications. Bonding ribbon, composed mainly of gold or aluminum, provides a wider cross-section that enhances current-carrying capacity and reduces electrical resistance in power applications. Both materials require precise control over purity and surface finish to ensure reliable wire bonding and optimal performance in integrated circuits.

Electrical Performance Comparison

Bonding wires typically offer lower inductance and higher flexibility, making them ideal for high-frequency applications due to their fine diameter and superior electrical conductivity. Bonding ribbons provide a larger cross-sectional area, resulting in lower resistance and enhanced current-carrying capacity, which is beneficial for power-intensive semiconductor devices. The choice between bonding wire and bonding ribbon depends on balancing electrical performance requirements such as inductance, resistance, and current capacity for specific integrated circuit designs.

Mechanical Strength and Durability

Bonding wire, typically made from gold, copper, or aluminum, offers superior mechanical strength for flexible connections in microelectronics, resisting deformation during thermal cycling. Bonding ribbon, with a larger cross-sectional area and flat geometry, provides enhanced durability and reduced electrical resistance, making it ideal for high-current applications. The ribbon's increased surface contact also improves heat dissipation, contributing to long-term reliability compared to traditional round wire bonds.

Applications in Semiconductor Packaging

Bonding wire, typically made of gold, copper, or aluminum, is widely used for fine-pitch interconnections in semiconductor packaging, offering flexibility and reliability in applications like IC encapsulation and sensor devices. Bonding ribbon, with its wider and flatter profile, is preferred for high-current applications such as power modules and LED packages, providing superior current-carrying capacity and reduced electrical resistance. Both bonding wire and bonding ribbon play critical roles in enhancing electrical performance and mechanical stability in advanced semiconductor packages.

Cost Implications and Manufacturing Efficiency

Bonding wire offers lower material costs and greater flexibility in automated handling, making it cost-effective for a wide range of semiconductor applications. Bonding ribbon, while generally more expensive due to its larger cross-sectional area and material volume, enables higher current carrying capacity and improved thermal performance, enhancing manufacturing efficiency for high-power devices. The choice between bonding wire and bonding ribbon depends on balancing initial material expenses against the efficiency gains in assembly processes and device reliability.

Reliability and Failure Modes

Bonding wire offers greater flexibility and resilience against mechanical stress, reducing the likelihood of fatigue failures compared to bonding ribbons, which are more susceptible to cracking under thermal cycling. Bonding ribbons provide superior electrical conductivity and lower inductance but can experience delamination or lift-off issues, leading to bond failure in high-vibration environments. Your choice between wire and ribbon should consider the specific reliability requirements and failure modes relevant to your application's operating conditions.

Selection Criteria for Bonding Solutions

Selection criteria for bonding solutions depend on electrical conductivity requirements, mechanical strength, and thermal management. Bonding wire offers flexibility and is ideal for fine-pitch connections, while bonding ribbon provides lower resistance and better current-carrying capacity for power applications. Material composition, such as gold, aluminum, or copper, influences performance and cost, making it essential to evaluate the application's electrical and environmental conditions.

Future Trends in Bonding Technology

Future trends in bonding technology emphasize the shift from traditional bonding wires to bonding ribbons due to their superior electrical conductivity and enhanced thermal dissipation capabilities. Innovations in ultra-fine bonding ribbons enable higher-density packaging and improved performance in advanced semiconductor devices. As microelectronics continue to demand miniaturization and reliability, bonding ribbons are poised to play a critical role in next-generation integrated circuit assembly.

Bonding Wire vs Bonding Ribbon Infographic

libmatt.com

libmatt.com