High aspect ratio etch creates deep, narrow features in materials with precise anisotropic profiles, enabling the fabrication of complex microstructures, while isotropic etch removes material uniformly in all directions, suitable for applications requiring smooth, rounded features. Choosing the right etching method depends on your specific microfabrication needs and desired feature geometries.

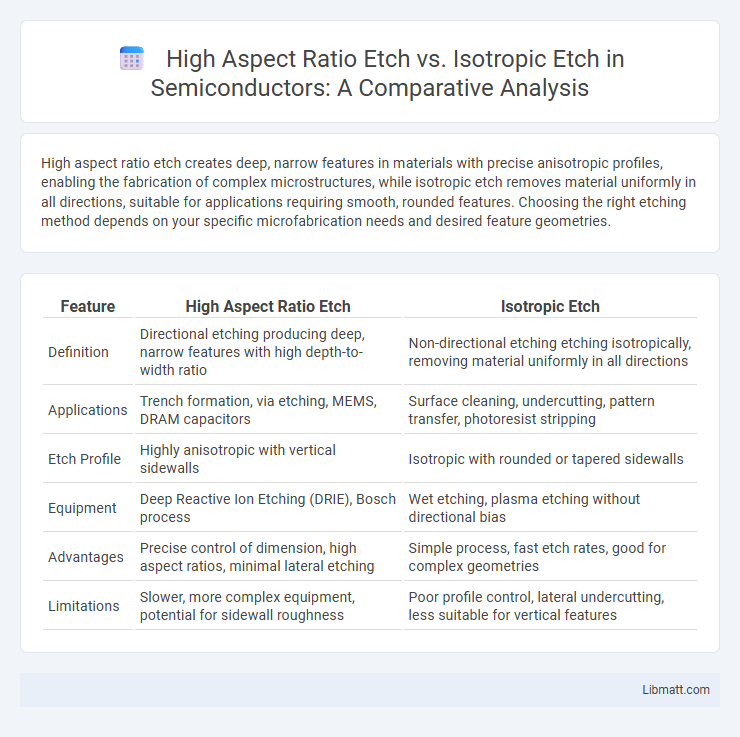

Table of Comparison

| Feature | High Aspect Ratio Etch | Isotropic Etch |

|---|---|---|

| Definition | Directional etching producing deep, narrow features with high depth-to-width ratio | Non-directional etching etching isotropically, removing material uniformly in all directions |

| Applications | Trench formation, via etching, MEMS, DRAM capacitors | Surface cleaning, undercutting, pattern transfer, photoresist stripping |

| Etch Profile | Highly anisotropic with vertical sidewalls | Isotropic with rounded or tapered sidewalls |

| Equipment | Deep Reactive Ion Etching (DRIE), Bosch process | Wet etching, plasma etching without directional bias |

| Advantages | Precise control of dimension, high aspect ratios, minimal lateral etching | Simple process, fast etch rates, good for complex geometries |

| Limitations | Slower, more complex equipment, potential for sidewall roughness | Poor profile control, lateral undercutting, less suitable for vertical features |

Introduction to Etching Techniques in Microfabrication

High aspect ratio etch processes enable precise, deep patterning critical for advanced microfabrication, producing highly anisotropic profiles with minimal undercutting. Isotropic etch techniques, by contrast, remove material uniformly in all directions, creating rounded, less defined features ideal for applications requiring smooth surfaces. Understanding these etching approaches helps optimize your device fabrication by selecting the appropriate method for feature shape and depth control.

Defining High Aspect Ratio Etch

High Aspect Ratio Etch (HARE) refers to a specialized etching process that creates deep and narrow features with a high height-to-width ratio, essential for advanced semiconductor devices and MEMS fabrication. Unlike isotropic etching, which removes material uniformly in all directions, HARE offers precise anisotropic profiles, ensuring vertical sidewalls and minimal lateral etch. Your choice of etching technique influences device performance by defining critical dimensions and structural integrity at the nanoscale.

Understanding Isotropic Etch

Isotropic etch uniformly removes material in all directions, resulting in rounded or undercut features commonly used for applications requiring smooth profiles or gentle edge definitions. Unlike high aspect ratio etch, which targets deep, narrow trenches with vertical sidewalls, isotropic etch provides lower precision but faster material removal over broader areas. Your choice between isotropic etch and high aspect ratio etch depends on the desired etch profile and feature geometry requirements in semiconductor or MEMS fabrication.

Key Differences Between High Aspect Ratio and Isotropic Etch

High Aspect Ratio Etch (HARE) produces deep, narrow features with vertical sidewalls, optimizing precision for microelectronic and MEMS device fabrication. In contrast, Isotropic Etch removes material uniformly in all directions, resulting in rounded corners and less control over feature dimensions. Your choice depends on whether you need precise anisotropic profiles or smoother, uniform etching for surface treatment.

Advantages of High Aspect Ratio Etching

High aspect ratio etching enables the creation of deep, narrow trenches with precise vertical sidewalls, essential for advanced semiconductor devices and MEMS fabrication. This technique improves device performance by allowing greater density and integration, enhancing electrical characteristics and thermal management. Your manufacturing process benefits from reduced feature distortion and better anisotropy control compared to isotropic etching.

Benefits and Limitations of Isotropic Etching

Isotropic etching offers the benefit of uniform material removal in all directions, making it ideal for applications requiring smooth, rounded features or gentle surface cleaning. Its main limitation is the lack of precision in creating fine, high aspect ratio structures, as the etch progresses laterally as well as vertically, potentially causing undercutting. Your choice of isotropic etching should balance the need for surface uniformity against the demand for detailed pattern fidelity.

Common Applications for Each Etching Method

High aspect ratio etch is commonly used in semiconductor fabrication for creating deep, narrow features such as trenches and vias in microelectromechanical systems (MEMS) and advanced integrated circuits. Isotropic etch finds frequent application in processes requiring uniform material removal, including surface cleaning, undercutting, and sacrificial layer release in microfabrication. The selection between high aspect ratio and isotropic etching depends on precision needs and the desired geometry of micro- and nanoscale structures.

Process Parameters Influencing Etch Profiles

Process parameters influencing etch profiles include gas composition, pressure, power, and etch time, which significantly affect the anisotropy and selectivity of both High Aspect Ratio (HAR) etch and isotropic etch. In HAR etch, low pressure and high bias power enhance directional ion bombardment, producing vertical sidewalls essential for deep feature definition, while isotropic etch uses higher pressure and more chemically reactive gases to achieve uniform material removal in all directions. Your control over these parameters determines etch precision, profile shape, and surface roughness critical for semiconductor fabrication and MEMS device manufacturing.

Challenges in Achieving Desired Etch Geometry

High Aspect Ratio Etch faces significant challenges in maintaining vertical sidewalls and uniform etch depth due to limited ion directionality and aspect ratio-dependent etching effects. Isotropic Etch, characterized by uniform material removal in all directions, often struggles with achieving precise geometries because lateral etching leads to undercutting and loss of pattern fidelity. Your process control must address these challenges by optimizing etch parameters such as plasma composition, pressure, and power to balance selectivity and anisotropy for desired etch profiles.

Future Trends in Etching Technology

Future trends in etching technology emphasize advancements in High Aspect Ratio Etch (HARE) processes, enabling more precise and deeper etching profiles essential for next-generation semiconductor manufacturing. Innovations in plasma and atomic layer etching (ALE) techniques aim to enhance anisotropy and selectivity, reducing damage while improving feature resolution in complex 3D structures. Your ability to leverage these cutting-edge etching technologies will drive higher device performance and scalability in emerging applications such as 3D NAND and advanced logic devices.

High Aspect Ratio Etch vs Isotropic Etch Infographic

libmatt.com

libmatt.com