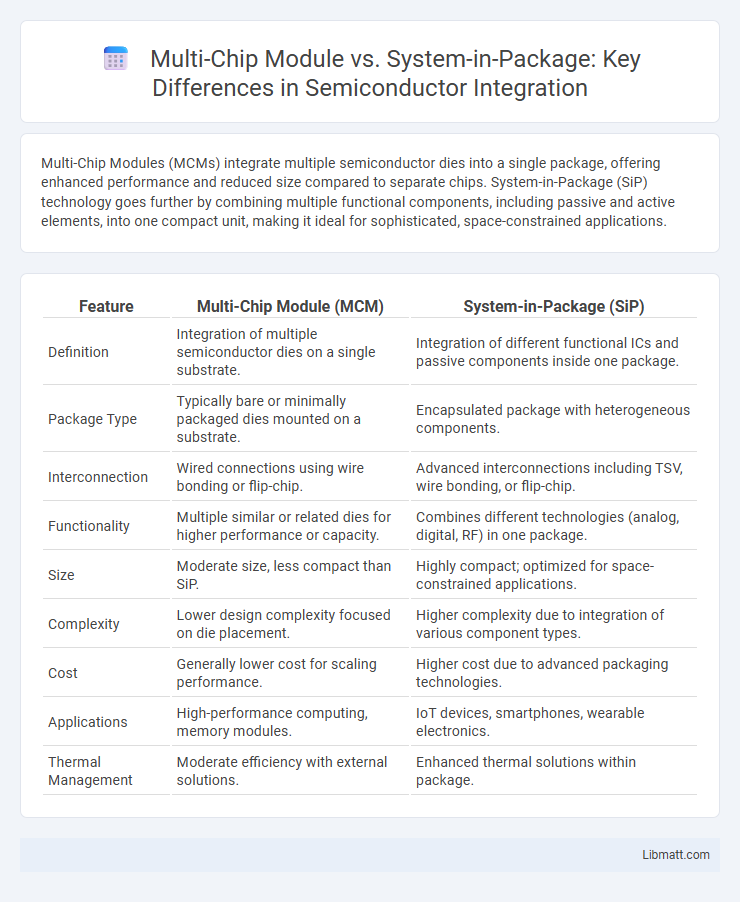

Multi-Chip Modules (MCMs) integrate multiple semiconductor dies into a single package, offering enhanced performance and reduced size compared to separate chips. System-in-Package (SiP) technology goes further by combining multiple functional components, including passive and active elements, into one compact unit, making it ideal for sophisticated, space-constrained applications.

Table of Comparison

| Feature | Multi-Chip Module (MCM) | System-in-Package (SiP) |

|---|---|---|

| Definition | Integration of multiple semiconductor dies on a single substrate. | Integration of different functional ICs and passive components inside one package. |

| Package Type | Typically bare or minimally packaged dies mounted on a substrate. | Encapsulated package with heterogeneous components. |

| Interconnection | Wired connections using wire bonding or flip-chip. | Advanced interconnections including TSV, wire bonding, or flip-chip. |

| Functionality | Multiple similar or related dies for higher performance or capacity. | Combines different technologies (analog, digital, RF) in one package. |

| Size | Moderate size, less compact than SiP. | Highly compact; optimized for space-constrained applications. |

| Complexity | Lower design complexity focused on die placement. | Higher complexity due to integration of various component types. |

| Cost | Generally lower cost for scaling performance. | Higher cost due to advanced packaging technologies. |

| Applications | High-performance computing, memory modules. | IoT devices, smartphones, wearable electronics. |

| Thermal Management | Moderate efficiency with external solutions. | Enhanced thermal solutions within package. |

Introduction to Multi-Chip Module (MCM) and System-in-Package (SiP)

Multi-Chip Module (MCM) integrates multiple integrated circuits (ICs) within a single package to enhance performance and reduce size, commonly used in high-speed computing and communications. System-in-Package (SiP) combines multiple functional components, including ICs, passives, and sensors, into a compact module to deliver complete systems with improved functionality and form factor. Choosing between MCM and SiP depends on Your design goals for integration complexity, performance, and manufacturing cost.

Fundamental Architecture Differences

Multi-Chip Modules (MCM) integrate multiple integrated circuits (ICs) within a single package, maintaining separate dies connected via a shared substrate, enabling modular design and easier yield optimization. System-in-Package (SiP) consolidates heterogeneous components, including ICs, passive devices, and sometimes sensors, into a single compact package with advanced interconnects such as wire bonds, flip-chip, or through-silicon vias (TSVs), facilitating higher integration density. The fundamental architecture difference lies in MCM's emphasis on packaging discrete chips side-by-side, while SiP achieves system-level integration by embedding diverse functional blocks within one unified package.

Integration Levels and Component Density

Multi-Chip Modules (MCM) integrate multiple integrated circuits on a single substrate, offering moderate component density by combining discrete chips without full system integration. System-in-Package (SiP) technology achieves higher integration levels by embedding various components, including processors, memory, and passive devices, within a single package, significantly increasing component density. SiP designs enable more compact and efficient solutions, ideal for applications demanding miniaturization and complex functionality.

Performance and Signal Integrity

Multi-Chip Modules (MCMs) provide superior performance through closely integrated chips connected with short interconnects, minimizing latency and enhancing signal integrity by reducing electromagnetic interference. In contrast, System-in-Package (SiP) solutions offer compact designs but may face signal integrity challenges due to heterogeneous component integration and longer interconnect paths. Optimizing your design with MCM can achieve higher data transfer rates and lower power consumption, crucial for high-speed applications requiring robust signal fidelity.

Power Consumption and Efficiency

Multi-Chip Modules (MCM) and System-in-Package (SiP) offer distinct advantages in power consumption and efficiency, with SiP generally providing better power optimization due to its integrated design that minimizes inter-chip communication losses. SiP architectures reduce parasitic capacitance and inductance by integrating multiple components within a single package, leading to lower power consumption and improved signal integrity compared to MCMs. MCMs, while offering flexibility in combining heterogeneous chips, typically exhibit higher power draw due to longer interconnects and less compact integration, resulting in lower energy efficiency.

Design Flexibility and Customization

Multi-Chip Modules (MCMs) offer higher design flexibility by allowing integration of multiple heterogeneous chips with distinct process technologies, enabling tailored customization for specific functionality. System-in-Package (SiP) solutions consolidate diverse components, such as processors, memory, and sensors, into a single package, optimizing space but often limiting individual chip customization due to tighter manufacturing constraints. The choice between MCM and SiP depends on the required trade-off between customization granularity and integration density for advanced semiconductor designs.

Manufacturing Complexity and Costs

Multi-Chip Modules (MCMs) involve assembling multiple semiconductor dies onto a single substrate, resulting in moderate manufacturing complexity but higher passive component integration costs. System-in-Package (SiP) technology integrates diverse components, including active and passive elements, within a single compact package, leading to increased manufacturing complexity and elevated production costs due to advanced fabrication and testing processes. Your choice between MCM and SiP impacts cost-efficiency and complexity based on the desired integration level and performance requirements.

Application Areas and Market Trends

Multi-Chip Modules (MCMs) are widely used in high-performance computing, aerospace, and telecommunications where integration of heterogeneous chips enhances processing power and reliability. System-in-Package (SiP) technology dominates consumer electronics, medical devices, and IoT applications due to its compact size and efficient power management. Market trends show a growing preference for SiP in miniaturized devices, while MCMs remain crucial for applications demanding high thermal performance and complex interconnectivity.

Scalability and Future Prospects

Multi-Chip Module (MCM) technology offers limited scalability due to physical package constraints and interconnect density challenges, impacting its adaptability to evolving computational demands. System-in-Package (SiP) solutions provide superior scalability by integrating heterogeneous components with advanced interconnects, enabling higher performance and reduced footprint for future-proof designs. Your choice between MCM and SiP will influence the potential for miniaturization, system complexity handling, and upgrade paths in cutting-edge electronic applications.

Choosing Between MCM and SiP: Key Considerations

Choosing between Multi-Chip Module (MCM) and System-in-Package (SiP) involves evaluating factors such as integration density, performance requirements, and system complexity. MCM offers flexibility with multiple dies placed on a single substrate, ideal for high-performance applications requiring heterogeneous components. Your decision should consider SiP's advantage in compactness and reduced signal interference for space-constrained designs demanding high reliability and power efficiency.

Multi-Chip Module vs System-in-Package Infographic

libmatt.com

libmatt.com