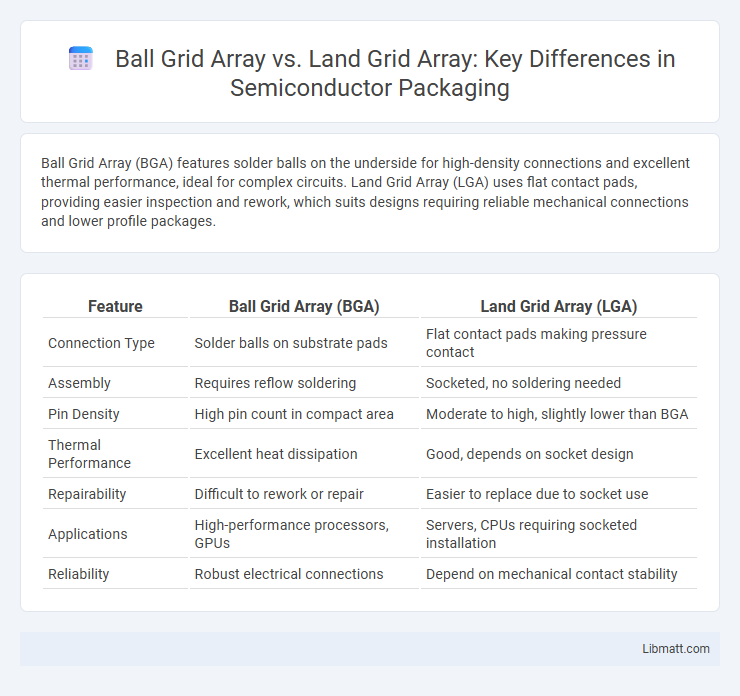

Ball Grid Array (BGA) features solder balls on the underside for high-density connections and excellent thermal performance, ideal for complex circuits. Land Grid Array (LGA) uses flat contact pads, providing easier inspection and rework, which suits designs requiring reliable mechanical connections and lower profile packages.

Table of Comparison

| Feature | Ball Grid Array (BGA) | Land Grid Array (LGA) |

|---|---|---|

| Connection Type | Solder balls on substrate pads | Flat contact pads making pressure contact |

| Assembly | Requires reflow soldering | Socketed, no soldering needed |

| Pin Density | High pin count in compact area | Moderate to high, slightly lower than BGA |

| Thermal Performance | Excellent heat dissipation | Good, depends on socket design |

| Repairability | Difficult to rework or repair | Easier to replace due to socket use |

| Applications | High-performance processors, GPUs | Servers, CPUs requiring socketed installation |

| Reliability | Robust electrical connections | Depend on mechanical contact stability |

Introduction to Ball Grid Array and Land Grid Array

Ball Grid Array (BGA) and Land Grid Array (LGA) are popular surface-mount packaging technologies used to connect integrated circuits to printed circuit boards. BGA packages utilize an array of solder balls on the underside of the chip for electrical connections, offering excellent thermal performance and reduced inductance. LGA packages feature flat contact pads on the chip that align with matching pads on the PCB, providing reliable mechanical stability and ease of inspection during assembly.

Overview of BGA and LGA Technologies

Ball Grid Array (BGA) technology features an array of solder balls beneath the integrated circuit package, providing efficient heat dissipation and reliable electrical interconnections for high-density applications. Land Grid Array (LGA) uses flat contact pads on the package that interface with pins on the socket, enabling ease of replacement and improved signal integrity. Both BGA and LGA are widely utilized in advanced microprocessor packaging, with BGA favored for permanent mounting and LGA preferred for socketed connections.

Structural Differences: BGA vs LGA

Ball Grid Array (BGA) packages feature solder balls arranged in a grid on the underside of the chip, allowing for direct soldering to the printed circuit board (PCB) and providing excellent electrical and thermal performance. Land Grid Array (LGA) packages have flat contact pads instead of solder balls, requiring a socket or mechanical force to maintain connection with the PCB, which simplifies inspection and repair but may introduce contact reliability concerns. The structural difference between BGA's solder balls and LGA's flat lands significantly impacts assembly methods, heat dissipation, and mechanical robustness in electronic applications.

Electrical Performance Comparison

Ball Grid Array (BGA) packages generally offer superior electrical performance compared to Land Grid Array (LGA) due to their solder ball connections, which provide lower electrical resistance and better signal integrity. BGA's shorter and more uniform interconnect paths reduce inductance and parasitic capacitance, enhancing high-frequency performance and minimizing signal loss. Your circuit benefits from improved power distribution and thermal management with BGA, resulting in more reliable high-speed electronic device operation.

Thermal Management in BGA vs LGA

Ball Grid Array (BGA) packages offer superior thermal management compared to Land Grid Array (LGA) designs due to the direct solder balls enabling efficient heat dissipation from the integrated circuit to the printed circuit board. BGA's closely packed solder balls provide a larger contact area facilitating enhanced thermal conductivity, which helps maintain lower operating temperatures and improves overall device reliability. For your high-performance applications requiring optimal heat transfer, BGA often outperforms LGA, which relies on surface contacts that may create higher thermal resistance.

Manufacturing and Assembly Processes

Ball Grid Array (BGA) packages feature solder balls on the underside that align with PCB pads, enabling automated reflow soldering and providing excellent mechanical strength and thermal performance. Land Grid Array (LGA) packages use flat contact lands requiring precise surface mounting and pressure contacts, often necessitating additional mechanical fixtures for reliable electrical connection during manufacturing. BGA assembly typically involves a single heating cycle for solder ball reflow, whereas LGA assembly demands careful alignment and may include complex socket designs to maintain contact integrity.

Reliability and Durability Factors

Ball Grid Array (BGA) packages offer superior reliability and durability due to their solder balls distributing mechanical stress evenly across the device, reducing the risk of joint failure during thermal cycling and mechanical shock. In contrast, Land Grid Array (LGA) packages rely on flat contacts that may be more susceptible to damage from physical wear and repeated mating cycles, impacting long-term performance. Your choice between BGA and LGA should consider the application's environmental conditions and expected mechanical stresses to ensure optimal device longevity.

Cost Analysis: BGA vs LGA

Ball Grid Array (BGA) packages generally offer lower overall production costs compared to Land Grid Array (LGA) due to their simpler PCB design and reduced need for expensive socket components. LGAs, while often more reliable for frequent testing and replacement, incur higher manufacturing and assembly costs because of intricate socket assemblies and tighter tolerances. Your choice between BGA and LGA should balance cost considerations with application requirements, as BGA minimizes package expenses but may increase repair complexity.

Common Applications for BGA and LGA

Ball Grid Array (BGA) packaging is commonly used in high-performance microprocessors, GPUs, and memory modules due to its efficient heat dissipation and high pin density. Land Grid Array (LGA) is frequently applied in CPUs and server processors where reliable electrical connections and easier socket installation are critical. Both packaging types support advanced electronics but differ in usage based on thermal management and mechanical requirements in consumer electronics, data centers, and communication devices.

Choosing the Right Package: Key Considerations

Choosing the right package between Ball Grid Array (BGA) and Land Grid Array (LGA) depends on factors such as electrical performance, thermal management, and mechanical reliability. BGA offers superior heat dissipation and higher pin density, making it ideal for high-performance applications, while LGA provides easier inspection and rework due to its flat contact pads. Consider the application's requirements for signal integrity, assembly complexity, and cost to determine the optimal package type.

Ball Grid Array vs Land Grid Array Infographic

libmatt.com

libmatt.com