Shallow trench technology creates narrow, low-depth trenches ideal for isolating components in integrated circuits with minimal substrate disturbance, while deep trench technology forms significantly deeper and wider trenches to provide enhanced isolation and reduce parasitic capacitance in high-performance devices. Choosing between shallow and deep trenches depends on your device's performance requirements and manufacturing constraints, balancing isolation effectiveness against process complexity.

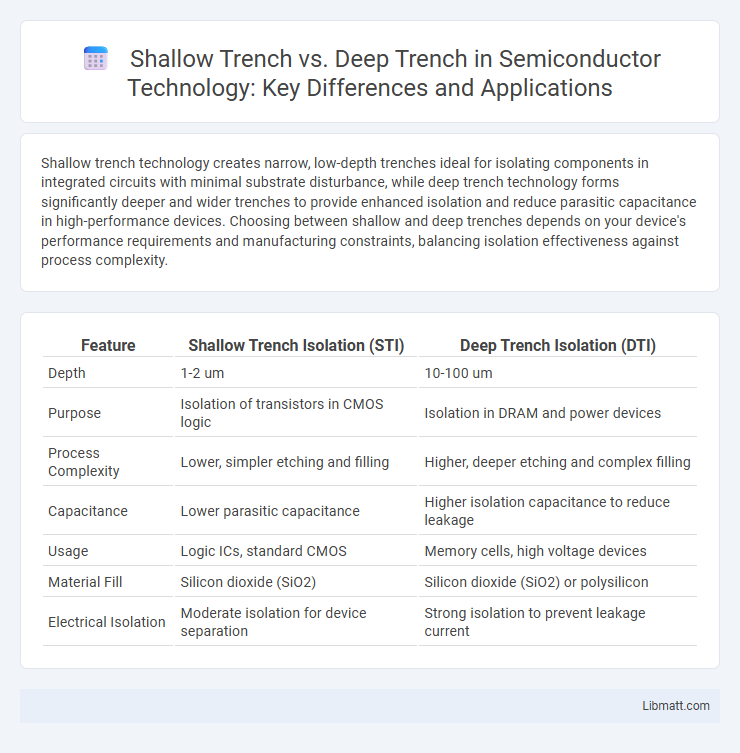

Table of Comparison

| Feature | Shallow Trench Isolation (STI) | Deep Trench Isolation (DTI) |

|---|---|---|

| Depth | 1-2 um | 10-100 um |

| Purpose | Isolation of transistors in CMOS logic | Isolation in DRAM and power devices |

| Process Complexity | Lower, simpler etching and filling | Higher, deeper etching and complex filling |

| Capacitance | Lower parasitic capacitance | Higher isolation capacitance to reduce leakage |

| Usage | Logic ICs, standard CMOS | Memory cells, high voltage devices |

| Material Fill | Silicon dioxide (SiO2) | Silicon dioxide (SiO2) or polysilicon |

| Electrical Isolation | Moderate isolation for device separation | Strong isolation to prevent leakage current |

Introduction to Shallow Trench and Deep Trench

Shallow trenches typically measure a few micrometers in depth and are used in semiconductor manufacturing for isolation between devices, offering reduced stress and simpler fabrication. Deep trenches extend tens of micrometers or more, enabling higher aspect ratios critical for applications like DRAM capacitors and MEMS structures, providing enhanced electrical isolation and mechanical support. Both trench types optimize device performance by tailoring depth and width to specific design and functional requirements.

Definitions: What are Shallow Trenches and Deep Trenches?

Shallow trenches are narrow and relatively shallow depressions in the ocean floor, usually less than 200 meters deep, formed by tectonic plate movements or sediment erosion. Deep trenches are much deeper, often exceeding 6,000 meters, created by subduction zones where one tectonic plate is forced beneath another, resulting in some of the ocean's most profound and geologically active areas. Your understanding of these features helps in comprehending oceanic geology and seismic activity patterns.

Key Differences Between Shallow and Deep Trenches

Shallow trenches, typically less than a few meters deep, are primarily used for minor utilities and drainage, while deep trenches extend several meters underground, accommodating larger infrastructure like pipelines and foundations. The key differences include depth, purpose, soil stability requirements, and cost, with deep trenches demanding more advanced engineering to prevent collapse. Shallow trenches are faster and cheaper to excavate but less suitable for heavy-duty applications compared to deep trenches that ensure structural integrity in complex construction projects.

Construction Methods for Shallow vs Deep Trenches

Shallow trench construction primarily involves manual excavation, use of basic machinery like backhoes, and simple shoring techniques to maintain trench stability due to limited depth and lower soil pressure. Deep trench construction requires advanced methods including trench boxes or hydraulic shoring systems to prevent collapse, heavy-duty excavation equipment, and sometimes slurry walls or caissons for stabilization under high hydrostatic pressure and complex soil conditions. Proper adherence to these construction methods ensures safety, structural integrity, and efficient project completion tailored to trench depth and site-specific geotechnical requirements.

Material Requirements and Costs

Shallow trench technology typically requires less material and lower-cost substrates compared to deep trench processes due to reduced etching depth and simpler fabrication steps. Deep trench structures demand more expensive high-purity silicon wafers and increased use of dielectric materials to ensure structural integrity and isolation, driving up overall costs. Material consumption and processing complexity in deep trenches substantially increase production expenses relative to shallow trench methods.

Applications: Where Each Trench Type is Used

Shallow trenches are commonly used in semiconductor devices for isolation and shallow junction formation due to their precision in defining small features on integrated circuits. Deep trenches find applications in advanced DRAM cells and power devices, where high aspect ratio structures enable enhanced charge storage and electrical isolation. Your choice between shallow and deep trench technology directly impacts device performance and scaling in microelectronics manufacturing.

Structural Stability and Safety Considerations

Deep trenches offer enhanced structural stability compared to shallow trenches due to their ability to better distribute lateral earth pressure and support heavier loads, making them ideal for large-scale construction projects. Shallow trenches, while more cost-effective and easier to dig, present higher risks of collapsing and require additional safety measures such as shoring or trench boxes to protect workers. Understanding these differences is crucial for your project's safety planning and compliance with industry regulations.

Advantages of Shallow Trenches

Shallow trenches offer advantages such as reduced cost and faster installation compared to deep trenches, making them ideal for residential and light commercial projects. They also minimize soil disturbance and lower the risk of groundwater contamination. These benefits contribute to easier maintenance and enhanced environmental protection in construction and utility applications.

Advantages of Deep Trenches

Deep trenches offer superior isolation for semiconductor devices by minimizing parasitic capacitance and leakage currents, significantly enhancing device performance and reliability. Their greater depth enables effective suppression of substrate noise and cross-talk, essential for high-frequency and analog circuits. Improved thermal dissipation is another advantage, allowing deep trenches to support higher power densities in advanced integrated circuits.

Choosing the Right Trench: Factors to Consider

Choosing the right trench depth depends on factors such as soil composition, moisture levels, and the purpose of the trench, with shallow trenches suited for irrigation and cable placement while deep trenches are essential for foundations and utility lines requiring protection. Evaluating load-bearing requirements, drainage needs, and environmental impact ensures the trench depth aligns with your project's structural integrity and safety standards. Properly selecting between shallow trench and deep trench solutions enhances durability, reduces maintenance costs, and supports long-term functionality.

Shallow Trench vs Deep Trench Infographic

libmatt.com

libmatt.com