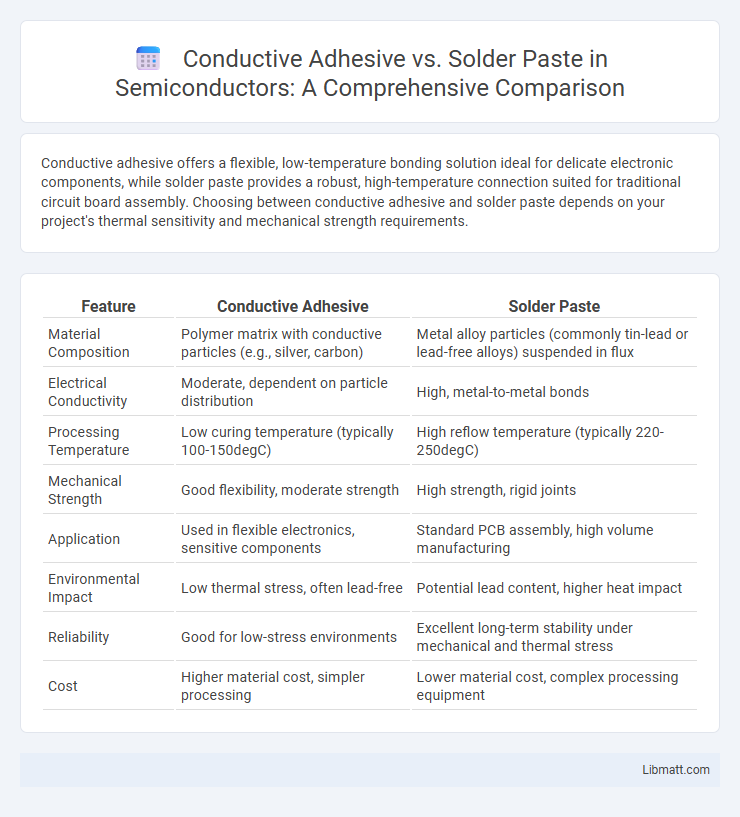

Conductive adhesive offers a flexible, low-temperature bonding solution ideal for delicate electronic components, while solder paste provides a robust, high-temperature connection suited for traditional circuit board assembly. Choosing between conductive adhesive and solder paste depends on your project's thermal sensitivity and mechanical strength requirements.

Table of Comparison

| Feature | Conductive Adhesive | Solder Paste |

|---|---|---|

| Material Composition | Polymer matrix with conductive particles (e.g., silver, carbon) | Metal alloy particles (commonly tin-lead or lead-free alloys) suspended in flux |

| Electrical Conductivity | Moderate, dependent on particle distribution | High, metal-to-metal bonds |

| Processing Temperature | Low curing temperature (typically 100-150degC) | High reflow temperature (typically 220-250degC) |

| Mechanical Strength | Good flexibility, moderate strength | High strength, rigid joints |

| Application | Used in flexible electronics, sensitive components | Standard PCB assembly, high volume manufacturing |

| Environmental Impact | Low thermal stress, often lead-free | Potential lead content, higher heat impact |

| Reliability | Good for low-stress environments | Excellent long-term stability under mechanical and thermal stress |

| Cost | Higher material cost, simpler processing | Lower material cost, complex processing equipment |

Introduction to Conductive Adhesive and Solder Paste

Conductive adhesive and solder paste are essential materials used for establishing electrical connections in electronics manufacturing. Conductive adhesive consists of polymer resin combined with conductive fillers, providing flexibility and strong bonding without high-temperature processing. Solder paste is a mixture of powdered solder and flux, designed for melting during reflow soldering to create reliable metallic joints on printed circuit boards.

Key Differences Between Conductive Adhesive and Solder Paste

Conductive adhesive offers a low-temperature, flexible bonding solution using polymer-based materials infused with conductive particles, ideal for sensitive components and flexible circuits. Solder paste relies on a mixture of powdered metal and flux, providing strong, rigid electrical and mechanical connections through high-temperature reflow soldering processes. Key differences include processing temperatures, mechanical flexibility, and the ability of conductive adhesive to bond dissimilar materials without thermal stress, contrasting with solder paste's superior electrical conductivity and mechanical strength.

Electrical Conductivity Comparison

Conductive adhesive offers moderate electrical conductivity ideal for flexible electronics and delicate components, while solder paste provides superior conductivity, ensuring robust and highly reliable electrical connections in demanding electronic assemblies. Your choice depends on the application's conductivity requirements and mechanical stress tolerance, as solder paste typically delivers lower resistance and better long-term performance. Understanding these electrical conductivity differences is crucial for optimizing circuit functionality and durability.

Mechanical Strength and Durability

Conductive adhesive offers flexible bonding with moderate mechanical strength, making it suitable for sensitive components and applications requiring vibration resistance. Solder paste provides superior durability and higher mechanical strength due to metallurgical bonding, which ensures reliable electrical connections under thermal and mechanical stress. Your choice between the two depends on the specific requirements for longevity and structural integrity in your electronic assembly.

Application Methods and Equipment Required

Conductive adhesive is typically applied using dispensing equipment such as syringes, jet dispensers, or screen printers, allowing precise control for delicate components and flexible substrates. Solder paste requires stencil printing or syringe dispensing followed by reflow ovens to achieve proper melting and bonding of electronic components. The equipment for conductive adhesive is generally simpler and operates at lower temperatures compared to the high-temperature reflow ovens essential for solder paste processing.

Suitable Use Cases and Industries

Conductive adhesive is ideal for flexible electronics, medical devices, and applications requiring low-temperature bonding, offering strong adhesion without heat damage. Solder paste suits high-temperature, precision electronics assembly in automotive, aerospace, and consumer electronics industries due to its excellent electrical conductivity and mechanical strength. Your choice depends on factors like thermal sensitivity, mechanical stress, and environmental conditions in these specific use cases.

Environmental and Safety Considerations

Conductive adhesive offers a safer alternative to solder paste by eliminating the need for high-temperature soldering, reducing the risk of burns and toxic fume exposure. Unlike solder paste, which often contains lead and requires flux that can emit harmful chemicals, conductive adhesives are typically lead-free and produce minimal environmental pollutants. Your choice between these materials should consider workplace safety and environmental regulations to minimize hazardous waste and ensure a healthier working environment.

Cost Analysis: Conductive Adhesive vs Solder Paste

Conductive adhesive generally incurs higher material costs compared to solder paste due to specialized polymers and conductive fillers like silver or carbon. Solder paste offers cost efficiency in mass production with lower-priced tin-based alloys and standardized dispensing methods. However, conductive adhesives reduce labor expenses by eliminating high-temperature processes, potentially offsetting initial material investment in specific applications.

Reliability and Performance in Real-World Scenarios

Conductive adhesive offers flexibility and corrosion resistance, making it ideal for delicate or flexible electronics, but generally exhibits lower thermal conductivity and mechanical strength compared to solder paste. Solder paste provides superior electrical conductivity, mechanical stability, and heat tolerance, ensuring long-term reliability in high-performance and high-temperature applications. In real-world scenarios, solder paste outperforms conductive adhesive where durability and consistent electrical connections are critical, while conductive adhesive suits applications requiring lightweight and non-rigid bonding solutions.

Choosing the Right Material for Your Project

When selecting between conductive adhesive and solder paste for your project, consider factors such as thermal tolerance, electrical conductivity, and application requirements. Conductive adhesive offers flexibility and ease of use for low-temperature or sensitive components, while solder paste provides strong mechanical bonds and high conductivity suited for demanding environments. Assess your project's operating conditions and assembly process to ensure optimal performance and reliability.

Conductive Adhesive vs Solder Paste Infographic

libmatt.com

libmatt.com