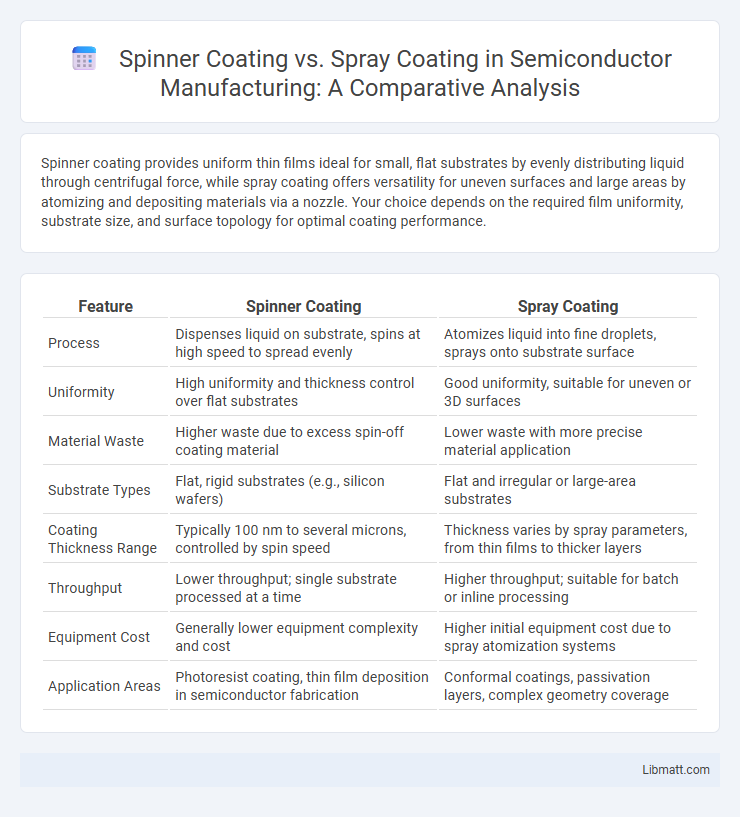

Spinner coating provides uniform thin films ideal for small, flat substrates by evenly distributing liquid through centrifugal force, while spray coating offers versatility for uneven surfaces and large areas by atomizing and depositing materials via a nozzle. Your choice depends on the required film uniformity, substrate size, and surface topology for optimal coating performance.

Table of Comparison

| Feature | Spinner Coating | Spray Coating |

|---|---|---|

| Process | Dispenses liquid on substrate, spins at high speed to spread evenly | Atomizes liquid into fine droplets, sprays onto substrate surface |

| Uniformity | High uniformity and thickness control over flat substrates | Good uniformity, suitable for uneven or 3D surfaces |

| Material Waste | Higher waste due to excess spin-off coating material | Lower waste with more precise material application |

| Substrate Types | Flat, rigid substrates (e.g., silicon wafers) | Flat and irregular or large-area substrates |

| Coating Thickness Range | Typically 100 nm to several microns, controlled by spin speed | Thickness varies by spray parameters, from thin films to thicker layers |

| Throughput | Lower throughput; single substrate processed at a time | Higher throughput; suitable for batch or inline processing |

| Equipment Cost | Generally lower equipment complexity and cost | Higher initial equipment cost due to spray atomization systems |

| Application Areas | Photoresist coating, thin film deposition in semiconductor fabrication | Conformal coatings, passivation layers, complex geometry coverage |

Introduction to Spinner Coating and Spray Coating

Spinner coating uses centrifugal force to evenly spread a liquid film across a flat surface, achieving uniform thickness ideal for semiconductor wafers and thin-film applications. Spray coating applies a fine mist of liquid onto a substrate, enabling coating of complex geometries and large areas with controlled thickness. Your choice between spinner coating and spray coating depends on the specific application requirements, substrate shape, and desired film uniformity.

Overview of Spinner Coating Technique

Spinner coating utilizes a high-speed rotating substrate to evenly distribute a liquid coating through centrifugal force, ensuring uniform thin film deposition for applications in microelectronics and optical devices. The technique achieves precise control over film thickness by adjusting spin speed, solution viscosity, and spin duration, making it ideal for producing consistent nanoscale coatings. Its efficiency in creating defect-free, homogenous layers distinguishes it from other coating methods like spray coating, especially for intricate or small-scale substrates.

Overview of Spray Coating Technique

Spray coating technique involves atomizing a liquid coating material into fine droplets and applying them uniformly onto a substrate, ensuring even coverage over complex shapes and large surface areas. This method allows for precise control of thickness, adhesion, and texture, making it suitable for industrial applications such as automotive, electronics, and protective coatings. You benefit from faster processing times and the ability to coat irregular geometries that are challenging for spinner coating methods.

Material Compatibility in Spinner and Spray Coating

Spinner coating offers excellent compatibility with low-viscosity liquids and uniform thin films on flat substrates, making it ideal for materials like photoresists, polymers, and sol-gels. Spray coating accommodates a broader range of material viscosities, including thicker solutions and particulate suspensions, providing versatility for coatings on complex surfaces and large areas. Your choice depends on the specific material properties and substrate geometry to ensure optimal film uniformity and adhesion.

Process Efficiency: Spinner Coating vs Spray Coating

Spinner coating offers higher process efficiency for uniform thin films with precise thickness control, making it ideal for flat substrates and small-scale applications. Spray coating provides greater versatility for complex geometries and larger surfaces but often requires multiple passes and longer drying times, reducing overall throughput. Your choice depends on balancing the need for speed, uniformity, and substrate complexity in your coating process.

Coating Uniformity and Thickness Control

Spinner coating offers superior uniformity and precise thickness control, making it ideal for applications requiring consistent thin films across flat substrates. Spray coating provides faster coverage over large or irregular surfaces but may result in variable thickness and less uniform coatings. Your choice depends on the need for exact layer control versus application speed and surface complexity.

Scalability and Industrial Applications

Spinner coating offers limited scalability due to its batch processing nature, making it ideal for laboratory-scale or small-area applications in industries like microelectronics and thin-film solar cells. Spray coating excels in scalability with continuous, large-area coating capabilities, widely adopted in automotive, aerospace, and manufacturing sectors for paints, coatings, and surface treatments. Industrial applications favor spray coating for high-volume production, while spinner coating remains preferable for precision thin-film fabrication requiring uniform layer deposition.

Cost Comparison: Equipment and Operations

Spinner coating typically involves higher initial equipment costs due to the need for precision spinning apparatus and controlled environment setups, whereas spray coating equipment is generally more affordable and offers flexibility in operation. Operational expenses for spinner coating can be elevated because of material waste and cleaning requirements, while spray coating often provides cost savings with efficient material usage and simpler maintenance. Your choice between these methods should consider the balance of initial investment against long-term operational costs and production volume demands.

Environmental and Safety Considerations

Spinner coating generates less airborne particulate matter compared to spray coating, reducing inhalation risks for workers and minimizing environmental contamination. Spray coating often requires solvents with higher VOC emissions, contributing to air pollution and necessitating rigorous ventilation and protective equipment to ensure safety. Implementing proper disposal and containment measures is critical for both methods to mitigate solvent waste and prevent soil and water contamination.

Final Recommendations and Application Scenarios

Spinner coating excels in producing uniform thin films on flat, small substrates, ideal for semiconductor wafer processing and microfabrication, while spray coating offers versatility on irregular surfaces and larger areas such as automotive parts and architectural glass. Your choice depends on precision needs and substrate geometry; use spinner coating for controlled thickness with minimal material waste and spray coating for scalable, flexible coverage on diverse materials. Consider production volume, cost efficiency, and surface complexity to match the coating technique with your specific application scenario.

Spinner Coating vs Spray Coating Infographic

libmatt.com

libmatt.com