Bulk Acoustic Wave (BAW) devices use acoustic waves that travel through the thickness of a material, offering higher frequency operation and better power handling, making them ideal for smartphone filters and high-frequency wireless communication. Surface Acoustic Wave (SAW) devices transmit waves along the surface of a material, providing excellent sensitivity and stability for RF filters in lower frequency ranges, thus optimizing Your signal processing in applications like GPS and radio receivers.

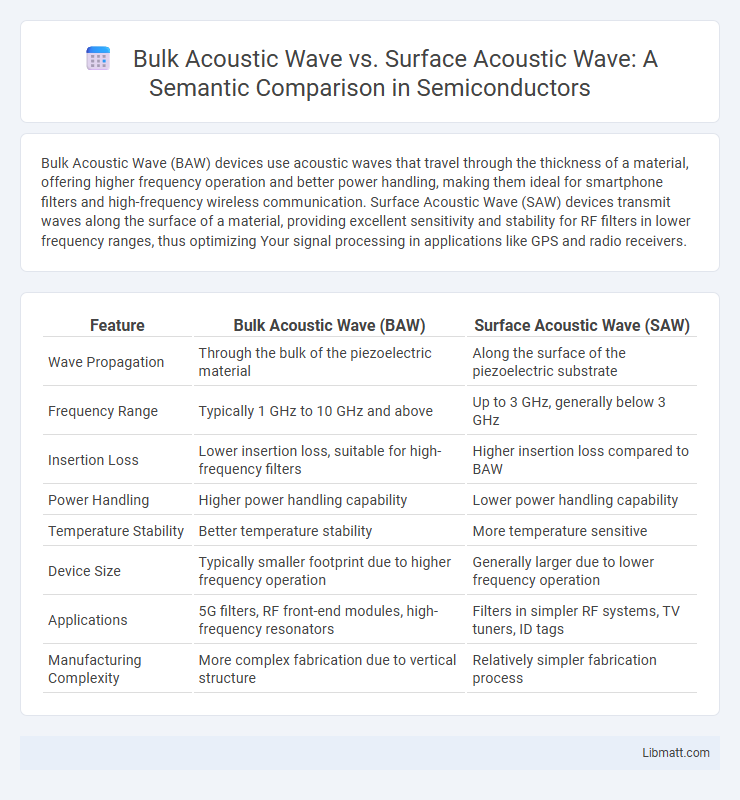

Table of Comparison

| Feature | Bulk Acoustic Wave (BAW) | Surface Acoustic Wave (SAW) |

|---|---|---|

| Wave Propagation | Through the bulk of the piezoelectric material | Along the surface of the piezoelectric substrate |

| Frequency Range | Typically 1 GHz to 10 GHz and above | Up to 3 GHz, generally below 3 GHz |

| Insertion Loss | Lower insertion loss, suitable for high-frequency filters | Higher insertion loss compared to BAW |

| Power Handling | Higher power handling capability | Lower power handling capability |

| Temperature Stability | Better temperature stability | More temperature sensitive |

| Device Size | Typically smaller footprint due to higher frequency operation | Generally larger due to lower frequency operation |

| Applications | 5G filters, RF front-end modules, high-frequency resonators | Filters in simpler RF systems, TV tuners, ID tags |

| Manufacturing Complexity | More complex fabrication due to vertical structure | Relatively simpler fabrication process |

Introduction to Acoustic Wave Technologies

Bulk Acoustic Wave (BAW) and Surface Acoustic Wave (SAW) technologies utilize mechanical vibrations for signal processing in filters and sensors, with BAW operating through acoustic waves traveling vertically through the substrate and SAW propagating waves along the surface. BAW devices typically offer higher frequency operation and better power handling capabilities, making them ideal for high-frequency mobile communication applications. SAW technology, valued for its lower insertion loss and ease of fabrication, is widely used in RF filters and touch-sensitive surfaces.

Defining Bulk Acoustic Wave (BAW)

Bulk Acoustic Wave (BAW) technology utilizes acoustic waves that propagate through the entire volume of a piezoelectric substrate, enabling efficient filtering and resonating functions in RF applications. BAW devices are preferred for their high frequency performance and excellent power handling capabilities, making them ideal for smartphone and wireless communication filters. Your choice of BAW over Surface Acoustic Wave (SAW) filters can enhance signal integrity and thermal stability in demanding environments.

Defining Surface Acoustic Wave (SAW)

Surface Acoustic Wave (SAW) devices utilize acoustic waves traveling along the surface of a material, typically piezoelectric substrates like quartz or lithium niobate, to process signals in filters and sensors. Compared to Bulk Acoustic Wave (BAW) devices, which transmit waves through the substrate thickness, SAW resonators offer high sensitivity and are widely used in telecommunications for frequency control and signal processing. Their surface-confined propagation makes SAW devices advantageous in applications requiring precise frequency stability and compact integration.

Key Differences Between BAW and SAW

Bulk Acoustic Wave (BAW) devices operate by generating acoustic waves that travel through the thickness of a piezoelectric material, whereas Surface Acoustic Wave (SAW) devices propagate waves along the surface of the material. BAW filters typically offer higher frequency ranges and better power handling, making them ideal for RF front-end applications in smartphones and wireless communication. Your choice between BAW and SAW depends on specific requirements such as frequency, bandwidth, and power, with BAW favored for higher frequencies and compact size, while SAW is preferred for lower frequencies and simpler integration.

Performance Characteristics: BAW vs SAW

Bulk Acoustic Wave (BAW) devices exhibit higher power handling and superior frequency stability compared to Surface Acoustic Wave (SAW) devices, making them ideal for high-frequency applications such as 5G communication systems. SAW filters offer lower insertion loss and better noise performance at lower frequencies, which suits applications like mobile handsets and RF front-end modules. Your choice between BAW and SAW should consider the specific frequency range and power requirements to optimize overall system performance.

Applications of Bulk Acoustic Wave Devices

Bulk Acoustic Wave (BAW) devices are widely used in high-frequency filters for RF front-end modules in smartphones, enabling enhanced signal processing and communication performance. BAW filters excel in applications requiring high power handling and thermal stability, such as cellular base stations and satellite communication systems. Their ability to operate efficiently at GHz frequencies makes them critical components in 5G wireless networks and advanced radar systems.

Applications of Surface Acoustic Wave Devices

Surface acoustic wave (SAW) devices are extensively utilized in mobile communication systems for signal processing tasks such as filtering, delay lines, and oscillators due to their high frequency and low insertion loss characteristics. They are critical components in touchscreens and sensors, converting mechanical waves into electrical signals for precise control and detection in consumer electronics and biomedical applications. SAW devices also enable advanced radio frequency identification (RFID) systems, offering enhanced performance in wireless data transfer and sensing in industrial environments.

Material Selection and Device Fabrication

Bulk Acoustic Wave (BAW) devices primarily utilize piezoelectric materials such as aluminum nitride (AlN) and lead zirconate titanate (PZT) for their high electromechanical coupling and acoustic velocity, enabling efficient device fabrication with thicker substrates. Surface Acoustic Wave (SAW) devices commonly employ quartz, lithium niobate, or lithium tantalate due to their superior surface wave generation and propagation characteristics, facilitating precise patterning through photolithography on thin-film substrates. Material selection in both technologies directly influences the fabrication processes, with BAW requiring complex bulk micromachining for high-Q resonators while SAW benefits from scalable surface patterning techniques to achieve desired frequency responses.

Market Trends and Industry Adoption

Bulk Acoustic Wave (BAW) technology is gaining significant traction in high-frequency applications like 5G and IoT due to its superior performance in handling wide bandwidths and high power levels. Surface Acoustic Wave (SAW) devices remain prominent in lower-frequency applications, benefiting from cost-effectiveness and established manufacturing processes. Your decision to adopt BAW or SAW filters should consider market trends favoring BAW for advanced wireless communication, while SAW maintains strong industry adoption in consumer electronics and automotive sectors.

Future Perspectives in Acoustic Wave Technology

Bulk Acoustic Wave (BAW) technology offers higher frequency performance and improved power handling, making it ideal for 5G and beyond wireless communication systems. Surface Acoustic Wave (SAW) devices continue to evolve with enhanced sensitivity for sensor applications and integration in IoT devices, driving advancements in environmental monitoring and healthcare. Future perspectives emphasize hybrid solutions combining BAW and SAW strengths to enable ultra-compact, energy-efficient acoustic wave filters and resonators for next-generation wireless networks.

Bulk Acoustic Wave vs Surface Acoustic Wave Infographic

libmatt.com

libmatt.com