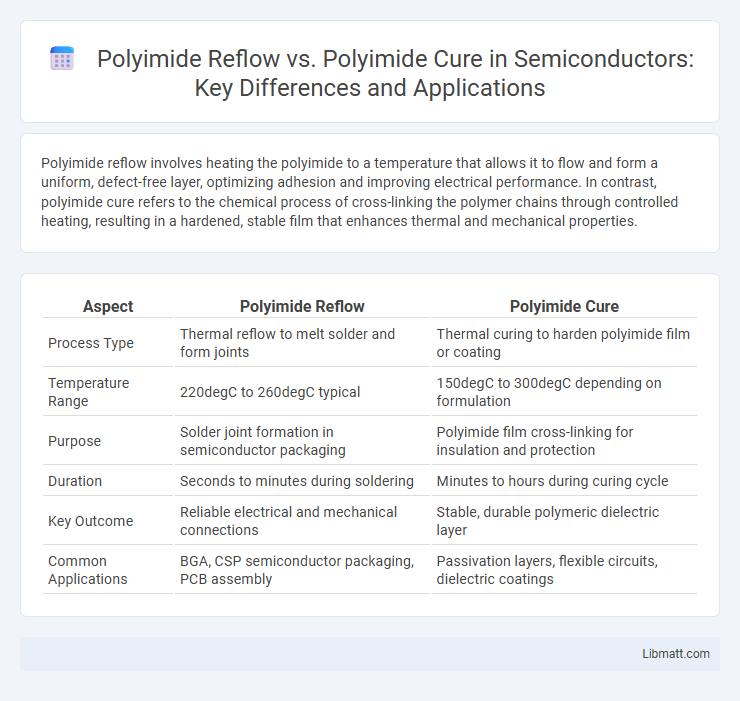

Polyimide reflow involves heating the polyimide to a temperature that allows it to flow and form a uniform, defect-free layer, optimizing adhesion and improving electrical performance. In contrast, polyimide cure refers to the chemical process of cross-linking the polymer chains through controlled heating, resulting in a hardened, stable film that enhances thermal and mechanical properties.

Table of Comparison

| Aspect | Polyimide Reflow | Polyimide Cure |

|---|---|---|

| Process Type | Thermal reflow to melt solder and form joints | Thermal curing to harden polyimide film or coating |

| Temperature Range | 220degC to 260degC typical | 150degC to 300degC depending on formulation |

| Purpose | Solder joint formation in semiconductor packaging | Polyimide film cross-linking for insulation and protection |

| Duration | Seconds to minutes during soldering | Minutes to hours during curing cycle |

| Key Outcome | Reliable electrical and mechanical connections | Stable, durable polymeric dielectric layer |

| Common Applications | BGA, CSP semiconductor packaging, PCB assembly | Passivation layers, flexible circuits, dielectric coatings |

Introduction to Polyimide Processing

Polyimide processing involves critical steps such as reflow and cure, each impacting material properties and application performance. Polyimide reflow refers to the phase where the polymer transitions to a flowable state under controlled temperature, enabling precise alignment and adhesion on substrates. Polyimide cure involves a thermal treatment that induces imidization, resulting in a thermally stable, highly durable film essential for electronic and aerospace components.

Understanding Polyimide Reflow

Polyimide reflow refers to the process of heating polyimide materials to a temperature where they soften and flow, enabling the formation of uniform coatings or bonding layers. This step is critical for achieving precise layer thickness and strong adhesion on substrates such as flexible electronics or microcircuits. Understanding polyimide reflow helps you optimize thermal profiles and ensure high-quality, defect-free polymer films in advanced manufacturing applications.

Overview of Polyimide Cure

Polyimide cure involves a thermal process that transforms the polymer precursor into a robust, thermally stable material through imidization. This step is critical for achieving the desired mechanical strength, chemical resistance, and electrical insulation properties essential in microelectronics and aerospace applications. Proper curing parameters such as temperature, time, and atmosphere directly influence the final polyimide film's performance and reliability.

Key Differences Between Reflow and Cure

Polyimide reflow involves heating the polyimide material to a temperature where it becomes soft and flows, enabling the formation of a uniform, void-free coating or adhesive layer. In contrast, polyimide cure refers to the thermal process that chemically cross-links the polyimide polymer chains, resulting in a stable, rigid, and thermally resistant structure. Understanding these key differences helps you optimize manufacturing processes, ensuring the desired mechanical and thermal properties in your final polyimide-based product.

Applications of Polyimide Reflow

Polyimide reflow is primarily used in electronics manufacturing for attaching components to flexible circuits, enabling high-temperature soldering without damaging sensitive parts. This process supports applications such as flexible printed circuit boards (FPCBs), chip-on-flex assemblies, and rigid-flex PCBs, enhancing mechanical reliability and thermal stability. Your devices benefit from polyimide reflow by achieving strong, durable interconnections essential for advanced miniaturized electronic systems.

Applications of Polyimide Cure

Polyimide cure is crucial in applications requiring outstanding thermal stability and chemical resistance, such as flexible printed circuit boards and high-performance electrical insulation. This curing process enhances the polymer's mechanical strength and dimensional stability, making it ideal for aerospace components and microelectromechanical systems (MEMS). The cured polyimide film maintains integrity under extreme temperatures, ensuring durability in demanding industrial and electronic environments.

Thermal Profiles: Reflow vs Cure

Polyimide reflow involves precise thermal profiles that rapidly heat and cool the material to achieve optimal solder joint formation without degrading the substrate. Polyimide cure, on the other hand, requires a controlled, prolonged heating cycle to fully polymerize the film, ensuring mechanical strength and chemical resistance. Your choice between reflow and cure thermal profiles depends on the specific application requirements, balancing the need for structural integrity versus soldering performance.

Impact on Material Properties

Polyimide reflow enhances adhesion and flexibility by partially melting the resin for improved interlayer bonding, while polyimide cure involves a complete chemical crosslinking process that increases thermal stability and mechanical strength. Your material's dielectric properties, moisture resistance, and thermal endurance benefit significantly from a thorough polyimide cure, which creates a robust, heat-resistant polymer matrix. In contrast, reflow primarily affects surface morphology and can influence subsequent processing steps without fully developing the intrinsic polymer characteristics.

Process Challenges and Solutions

Polyimide reflow often faces challenges with precise temperature control to avoid thermal degradation, while polyimide cure demands uniform heat distribution to ensure consistent film properties. Solutions include advanced temperature profiling and real-time monitoring systems that maintain optimal thermal conditions during both processes. Your manufacturing efficiency and product reliability improve significantly by addressing these specific process challenges through tailored thermal management techniques.

Choosing the Right Process for Your Application

Selecting between polyimide reflow and polyimide cure depends on the specific thermal and mechanical requirements of your application. Polyimide reflow involves melting and resolidifying, ideal for reworkable electronic substrates, while polyimide cure forms a robust, stable polymer network suited for high-temperature, high-stress environments. Evaluating factors such as temperature tolerance, chemical resistance, and mechanical durability ensures the optimal process enhances performance and reliability in your chosen application.

Polyimide Reflow vs Polyimide Cure Infographic

libmatt.com

libmatt.com