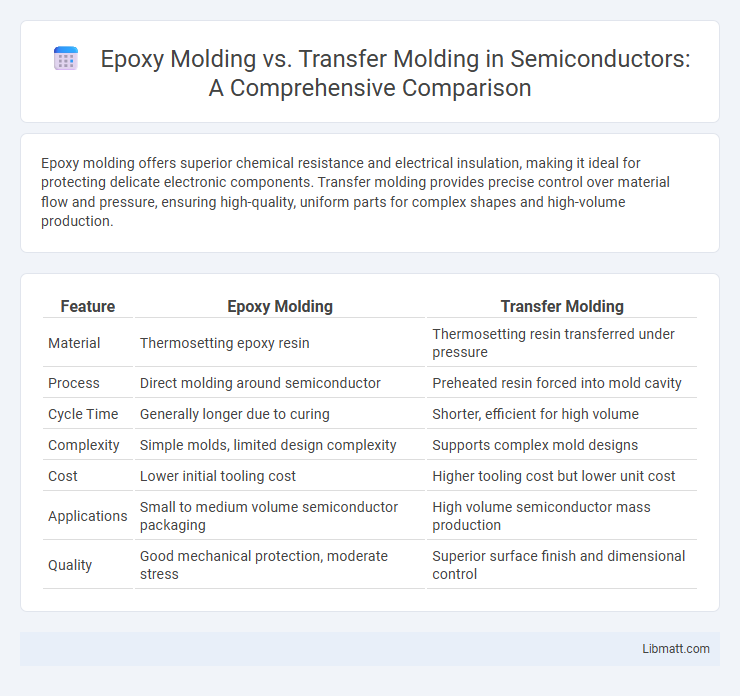

Epoxy molding offers superior chemical resistance and electrical insulation, making it ideal for protecting delicate electronic components. Transfer molding provides precise control over material flow and pressure, ensuring high-quality, uniform parts for complex shapes and high-volume production.

Table of Comparison

| Feature | Epoxy Molding | Transfer Molding |

|---|---|---|

| Material | Thermosetting epoxy resin | Thermosetting resin transferred under pressure |

| Process | Direct molding around semiconductor | Preheated resin forced into mold cavity |

| Cycle Time | Generally longer due to curing | Shorter, efficient for high volume |

| Complexity | Simple molds, limited design complexity | Supports complex mold designs |

| Cost | Lower initial tooling cost | Higher tooling cost but lower unit cost |

| Applications | Small to medium volume semiconductor packaging | High volume semiconductor mass production |

| Quality | Good mechanical protection, moderate stress | Superior surface finish and dimensional control |

Introduction to Epoxy Molding and Transfer Molding

Epoxy molding utilizes thermosetting epoxy resins to encapsulate electronic components, providing excellent moisture resistance and mechanical strength. Transfer molding involves forcing molten compound into a mold cavity to form precise shapes, commonly used for packaging semiconductor devices. Understanding these processes helps you select the optimal method for durability and performance in your manufacturing applications.

Understanding the Basics: What is Epoxy Molding?

Epoxy molding involves encapsulating electronic components with a thermosetting epoxy resin to provide insulation, protection, and mechanical support. This process cures the resin under heat and pressure, resulting in a durable, moisture-resistant coating ideal for semiconductor packaging. Compared to transfer molding, epoxy molding offers enhanced adhesion and superior chemical resistance, making it suitable for high-reliability applications.

Overview of the Transfer Molding Process

Transfer molding involves placing a pre-measured amount of molded material into a heated pot, where it is then forced under pressure through a runner system into a mold cavity, ensuring precise filling and consistent shape formation. This process allows for complex geometries and tight tolerances while minimizing material waste compared to other methods like epoxy molding. Understanding transfer molding can help you select the optimal manufacturing technique for high-volume production of durable, high-performance plastic parts.

Key Differences Between Epoxy Molding and Transfer Molding

Epoxy molding involves curing a two-part epoxy resin under heat and pressure to encapsulate electronic components, offering excellent chemical resistance and mechanical strength. Transfer molding, on the other hand, uses preheated polymer material transferred into a mold cavity to form precise, high-volume parts with uniform thickness. Your choice between these techniques depends on factors like production volume, material properties, and desired component durability.

Material Compatibility and Selection Criteria

Epoxy molding offers superior chemical resistance and thermal stability, making it ideal for applications requiring durability with complex electronic components, while transfer molding excels in processing thermoplastics and thermosets with high precision and minimal material waste. Material compatibility depends on factors such as thermal expansion, moisture sensitivity, and mechanical strength, which influence your selection between epoxy's rigid, adhesive properties and transfer molding's ability to incorporate fillers and reinforcements. Choosing the right molding technique involves assessing the specific material behavior under operational conditions to ensure optimal performance and longevity of the final product.

Process Efficiency and Cycle Times

Epoxy molding offers faster cycle times due to its lower curing temperature and shorter curing duration compared to transfer molding, which requires higher heat and pressure for resin flow. Transfer molding generally involves more complex mold designs and longer setup times, reducing overall process efficiency in high-volume production. Epoxy molding's streamlined process enhances throughput while maintaining precision, making it more suitable for rapid prototyping and small to medium batch manufacturing.

Typical Applications for Each Molding Technique

Epoxy molding is commonly used in electronic packaging, providing superior protection for semiconductor devices in harsh environments such as automotive and industrial applications. Transfer molding is ideal for encapsulating integrated circuits and electronic components on a large scale due to its high efficiency and precise control over resin flow. Your product requirements and production volume will determine whether epoxy or transfer molding is better suited for your application.

Cost Analysis: Epoxy Molding vs Transfer Molding

Epoxy molding generally incurs higher material costs due to the premium nature of epoxy resins, while transfer molding benefits from lower raw material expenses using thermosetting plastics. Transfer molding offers cost-effective scalability for high-volume production runs, resulting in decreased per-unit costs compared to epoxy molding. Your choice between epoxy and transfer molding should consider initial tooling investments, cycle times, and material waste to optimize overall cost efficiency.

Quality, Strength, and Performance Comparison

Epoxy molding offers superior chemical resistance and thermal stability, making it ideal for high-reliability applications, while transfer molding provides excellent dimensional control and is cost-effective for large production volumes. The strength of epoxy molding stems from its robust polymer matrix, delivering enhanced mechanical properties, whereas transfer molding ensures consistent encapsulation with minimal voids, boosting overall device performance. Your choice depends on balancing the need for exceptional durability in harsh environments with the efficiency and precision required for mass manufacturing.

Choosing the Right Molding Process for Your Project

Epoxy molding offers superior chemical resistance and electrical insulation ideal for high-performance electronic components, while transfer molding excels in producing complex shapes with exceptional dimensional accuracy. Selecting the right molding process depends on factors such as material properties, component design complexity, and production volume requirements. Evaluating thermal stability, mechanical strength, and cost-effectiveness will guide the optimal choice between epoxy and transfer molding for your project needs.

Epoxy Molding vs Transfer Molding Infographic

libmatt.com

libmatt.com