Lithography uses a flat surface and relies on the repulsion of oil and water to create prints, while etching involves scratching a design onto a metal plate coated with a protective ground and then using acid to bite into the exposed areas. Your choice depends on the desired texture and intricacy, with lithography offering smooth gradations and etching providing detailed line work.

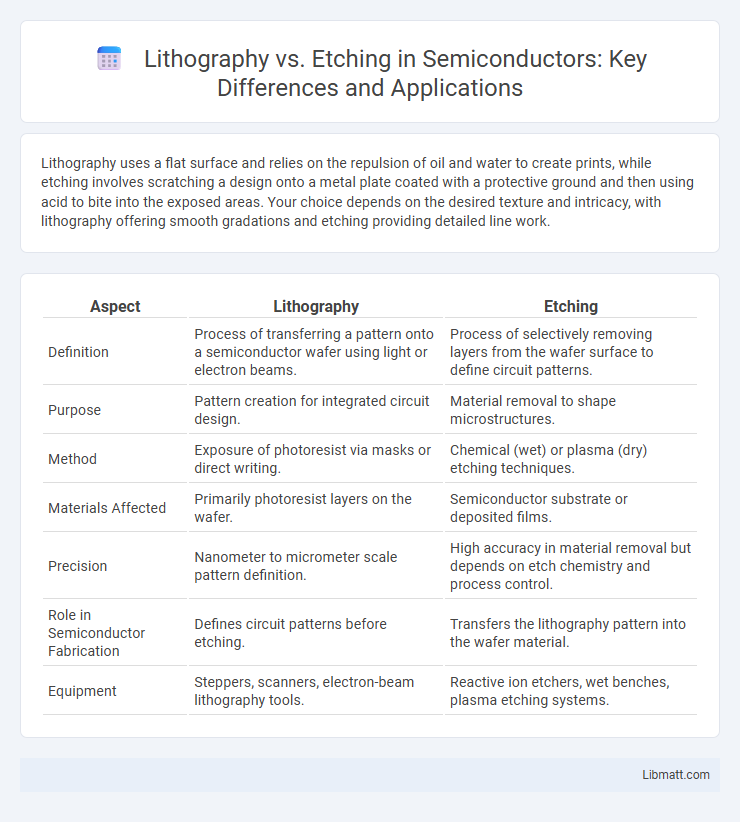

Table of Comparison

| Aspect | Lithography | Etching |

|---|---|---|

| Definition | Process of transferring a pattern onto a semiconductor wafer using light or electron beams. | Process of selectively removing layers from the wafer surface to define circuit patterns. |

| Purpose | Pattern creation for integrated circuit design. | Material removal to shape microstructures. |

| Method | Exposure of photoresist via masks or direct writing. | Chemical (wet) or plasma (dry) etching techniques. |

| Materials Affected | Primarily photoresist layers on the wafer. | Semiconductor substrate or deposited films. |

| Precision | Nanometer to micrometer scale pattern definition. | High accuracy in material removal but depends on etch chemistry and process control. |

| Role in Semiconductor Fabrication | Defines circuit patterns before etching. | Transfers the lithography pattern into the wafer material. |

| Equipment | Steppers, scanners, electron-beam lithography tools. | Reactive ion etchers, wet benches, plasma etching systems. |

Introduction to Lithography and Etching

Lithography is a printing process that uses a flat stone or metal plate treated to repel ink except on desired image areas, based on the principle that oil and water do not mix. Etching involves using acid or other chemicals to cut into a metal surface, creating incised lines that hold ink for printing. Both techniques are fundamental in art and manufacturing, offering distinct methods of image creation and surface manipulation.

Historical Background of Lithography and Etching

Lithography, invented by Alois Senefelder in 1796, revolutionized printmaking by using a flat stone surface and oil-based inks to create images, allowing artists and printers new creative freedom. Etching, with roots tracing back to the 16th century, involves acid biting into metal plates, offering detailed line work and tonal variations essential for fine art and map reproduction. Understanding the historical development of lithography and etching enhances your appreciation for their unique roles in artistic expression and printing technology evolution.

Core Principles: How Lithography Works

Lithography operates on the core principle of using a flat surface treated to repel ink except where a design is drawn with a grease-based medium, allowing ink to adhere only to the drawn areas for printing. This technique relies on the natural repulsion between oil and water, using a wet surface that selectively accepts ink on hydrophobic regions while repelling it on hydrophilic areas. Your understanding of these fundamental interactions helps clarify why lithography is ideal for producing high-quality, detailed images in art and printing industries.

Core Principles: How Etching Works

Etching operates by using acid or other chemicals to selectively dissolve parts of a metal surface, creating a design based on a resist-coated pattern. The process relies on precise application of the resist material, which protects specific areas from the etching solution, allowing for detailed and controlled image transfer onto the substrate. Understanding how etching works enables you to achieve high-resolution patterns essential for applications in printmaking, semiconductor fabrication, and microengineering.

Materials Used in Lithography vs Etching

Lithography primarily uses photoresists, such as positive and negative tone resists, applied on substrates like silicon wafers or glass for intricate pattern transfer. Etching involves materials like acids (e.g., hydrofluoric acid, nitric acid) or plasma gases (e.g., CF4, SF6) to selectively remove parts of the substrate or deposited layers. The distinct material requirements reflect lithography's reliance on light-sensitive compounds for pattern definition, whereas etching depends on chemical or plasma reactions for material removal.

Artistic Styles and Applications

Lithography enables artists to create detailed, tonal images using grease-based inks on stone or metal plates, making it ideal for producing smooth gradients and subtle textures in fine art prints and posters. Etching involves using acid to carve intricate lines into metal plates, allowing for precise, sharp details and a wide range of line qualities suited for expressive and complex designs in printmaking and decorative arts. Both techniques are foundational in printmaking, with lithography favored for its versatility in replicating brushwork and etching prized for its ability to produce rich line work and depth.

Technical Processes: Step-by-Step Comparison

Lithography involves coating a substrate with a photosensitive resist, exposing it to patterned light, and developing the image to create precise microstructures, primarily used in semiconductor manufacturing. Etching follows lithography by selectively removing material from the substrate surface through chemical or plasma processes, either wet or dry, to transfer the pattern defined by the resist. The combined workflow of lithography patterning and etching material removal enables the fabrication of intricate microelectronic circuits and microelectromechanical systems with nanoscale accuracy.

Advantages and Limitations of Lithography

Lithography offers high precision and scalability for intricate pattern creation on semiconductor wafers, making it essential in microchip manufacturing. It enables rapid production with excellent reproducibility but struggles with limitations such as resolution constraints at extremely small scales and sensitivity to surface contamination. The process efficiency relies heavily on advanced photomask quality and light wavelength, which can increase costs and complexity in cutting-edge applications.

Advantages and Limitations of Etching

Etching offers precise control over material removal, allowing for detailed pattern transfer crucial in semiconductor fabrication and microelectromechanical systems (MEMS). Its advantages include high resolution and compatibility with various substrates, but limitations arise from potential undercutting, chemical handling hazards, and slower processing times compared to lithography. Understanding your specific application needs ensures optimal selection between etching and lithography for manufacturing efficiency and product performance.

Choosing Between Lithography and Etching

Choosing between lithography and etching depends on the desired level of precision and material compatibility in microfabrication. Lithography offers superior pattern resolution for intricate circuit designs, while etching provides effective material removal for defining microstructures on various substrates. Evaluating factors such as feature size requirements, substrate type, and process complexity ensures optimal results in semiconductor manufacturing.

Lithography vs Etching Infographic

libmatt.com

libmatt.com