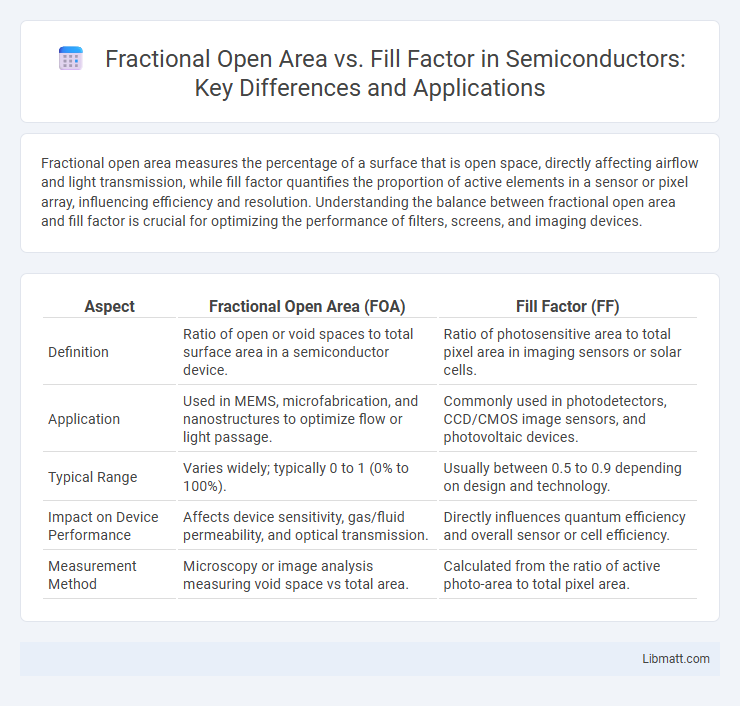

Fractional open area measures the percentage of a surface that is open space, directly affecting airflow and light transmission, while fill factor quantifies the proportion of active elements in a sensor or pixel array, influencing efficiency and resolution. Understanding the balance between fractional open area and fill factor is crucial for optimizing the performance of filters, screens, and imaging devices.

Table of Comparison

| Aspect | Fractional Open Area (FOA) | Fill Factor (FF) |

|---|---|---|

| Definition | Ratio of open or void spaces to total surface area in a semiconductor device. | Ratio of photosensitive area to total pixel area in imaging sensors or solar cells. |

| Application | Used in MEMS, microfabrication, and nanostructures to optimize flow or light passage. | Commonly used in photodetectors, CCD/CMOS image sensors, and photovoltaic devices. |

| Typical Range | Varies widely; typically 0 to 1 (0% to 100%). | Usually between 0.5 to 0.9 depending on design and technology. |

| Impact on Device Performance | Affects device sensitivity, gas/fluid permeability, and optical transmission. | Directly influences quantum efficiency and overall sensor or cell efficiency. |

| Measurement Method | Microscopy or image analysis measuring void space vs total area. | Calculated from the ratio of active photo-area to total pixel area. |

Understanding Fractional Open Area and Fill Factor

Fractional Open Area represents the percentage of open space in a material, crucial in applications like filtration, ventilation, and acoustics, impacting flow and light transmission properties. Fill Factor quantifies the ratio of the active area to the total area in devices such as solar panels or sensors, affecting efficiency and performance. Understanding the relationship between Fractional Open Area and Fill Factor helps optimize material design and device functionality by balancing openness and active surface coverage.

Key Definitions: Fractional Open Area vs Fill Factor

Fractional Open Area (FOA) refers to the ratio of the open space or gaps in a material to the total surface area, directly affecting light transmission, airflow, and acoustic properties. Fill Factor measures the proportion of the solid material area relative to the entire surface, influencing structural strength and opacity. Understanding the distinction between FOA and Fill Factor is crucial for optimizing design parameters in applications like filters, screens, and ventilation systems.

Importance in Industrial Applications

Fractional open area and fill factor critically influence airflow, filtration efficiency, and structural integrity in industrial applications like HVAC systems, filtration units, and acoustic panels. Optimizing fractional open area enhances ventilation and reduces pressure drop while balancing fill factor ensures material strength and durability under operational stresses. Precise design leveraging these parameters increases equipment performance and energy efficiency, directly impacting process reliability and maintenance costs.

Measurement Techniques for Fractional Open Area

Measurement techniques for fractional open area primarily include image analysis, porometry, and microscopy methods. Image analysis uses high-resolution photographs combined with software algorithms to quantify open spaces accurately. Porometry measures the flow rate of gases or liquids through the porous material, providing indirect but precise fractional open area data essential for optimizing Your filter or membrane performance.

Determining Fill Factor in Engineering Design

Determining fill factor in engineering design involves calculating the ratio of the open area to the total area of a structured surface, which is critical for optimizing performance characteristics such as airflow, light transmission, or heat dissipation. Engineers use fractional open area measurements to precisely quantify fill factor, ensuring material efficiency and functional effectiveness in applications like filters, solar panels, and perforated metals. Accurate fill factor determination enables the balance of structural integrity with desired permeability or transparency for tailored engineering solutions.

Comparative Analysis: Fractional Open Area vs Fill Factor

Fractional Open Area (FOA) measures the proportion of open space on a surface, while Fill Factor (FF) represents the ratio of the active or filled area to the total area in applications like solar cells or sensors. FOA directly influences airflow and light transmission efficiency, whereas FF affects device performance by determining how much active material is present to capture or process energy. Understanding the quantitative relationship between Fractional Open Area and Fill Factor helps optimize design parameters for improved functionality in filtration, photovoltaics, and optical systems.

Impact on Performance and Efficiency

Fractional open area and fill factor crucially influence the performance and efficiency of sensors and optical devices by controlling light transmission and mechanical strength. A higher fractional open area increases light throughput, enhancing sensitivity and signal accuracy, while a lower fill factor tends to improve structural integrity but may reduce active sensing surface. Balancing these parameters allows you to optimize device efficiency for applications requiring precise light management and durable design.

Challenges in Accurate Calculation

Accurate calculation of fractional open area and fill factor is challenged by the complexity of geometrical patterns and variations in micro-scale features, which often lead to discrepancies in measurement results. High-resolution imaging and precise computational algorithms are required to capture irregularities and non-uniformities in the material structure, but noise and resolution limits can introduce errors. Integrating advanced image processing techniques with robust statistical models improves the reliability of these calculations, essential for optimizing designs in applications like filtration, photonics, and microfabrication.

Optimizing Designs with Open Area and Fill Factor

Optimizing designs with fractional open area and fill factor enhances device performance by maximizing light transmission while maintaining structural integrity. High fractional open area improves airflow and reduces weight, whereas an optimized fill factor ensures uniformity in pixel or aperture distribution, critical for sensors and displays. Balancing these parameters enables efficient energy utilization and improved sensitivity in applications such as imaging, ventilation, and filtration systems.

Future Trends in Materials and Structural Analysis

Future trends in materials for fractional open area and fill factor optimization emphasize the use of advanced composites and metamaterials to achieve higher precision in microstructural design. Structural analysis techniques are evolving with machine learning algorithms and finite element modeling, allowing for enhanced prediction of mechanical properties and performance under various loading conditions. These innovations drive the development of lightweight, high-strength materials with improved airflow or light transmission, critical for applications in aerospace, electronics, and filtration systems.

Fractional Open Area vs Fill Factor Infographic

libmatt.com

libmatt.com