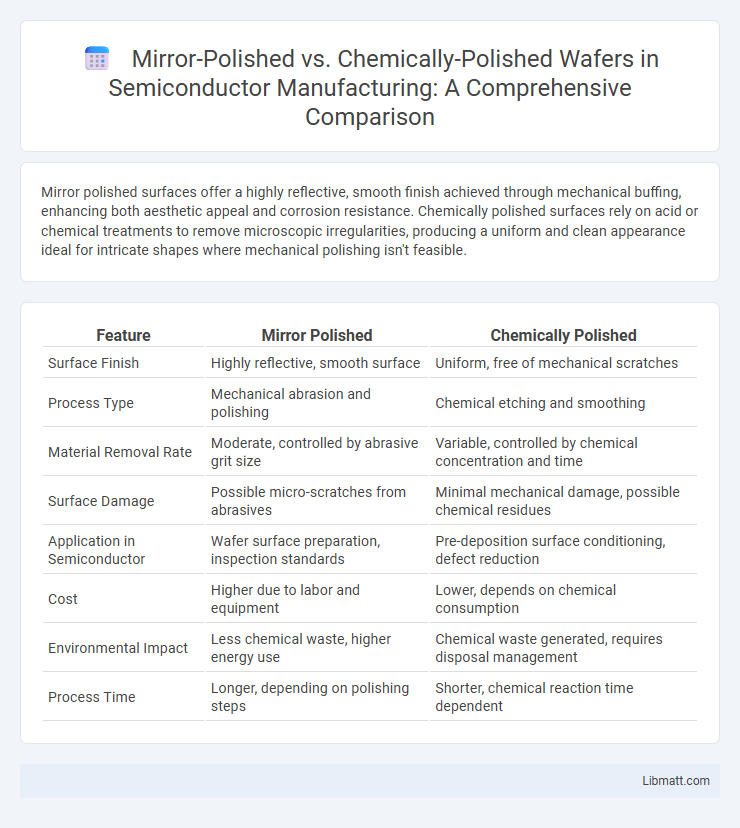

Mirror polished surfaces offer a highly reflective, smooth finish achieved through mechanical buffing, enhancing both aesthetic appeal and corrosion resistance. Chemically polished surfaces rely on acid or chemical treatments to remove microscopic irregularities, producing a uniform and clean appearance ideal for intricate shapes where mechanical polishing isn't feasible.

Table of Comparison

| Feature | Mirror Polished | Chemically Polished |

|---|---|---|

| Surface Finish | Highly reflective, smooth surface | Uniform, free of mechanical scratches |

| Process Type | Mechanical abrasion and polishing | Chemical etching and smoothing |

| Material Removal Rate | Moderate, controlled by abrasive grit size | Variable, controlled by chemical concentration and time |

| Surface Damage | Possible micro-scratches from abrasives | Minimal mechanical damage, possible chemical residues |

| Application in Semiconductor | Wafer surface preparation, inspection standards | Pre-deposition surface conditioning, defect reduction |

| Cost | Higher due to labor and equipment | Lower, depends on chemical consumption |

| Environmental Impact | Less chemical waste, higher energy use | Chemical waste generated, requires disposal management |

| Process Time | Longer, depending on polishing steps | Shorter, chemical reaction time dependent |

Introduction to Metal Polishing Techniques

Metal polishing techniques transform surface finishes to enhance both appearance and corrosion resistance, with mirror polishing producing a highly reflective, almost glass-like surface by mechanically buffing the metal. Chemically polished finishes rely on acid or alkaline solutions to smoothly dissolve surface irregularities, resulting in a uniform and matte or semi-gloss texture without mechanical abrasion. Depending on your project's aesthetic and functional requirements, choosing between mirror polished and chemically polished metals will impact the final sheen, texture, and long-term durability of the material.

What is Mirror Polishing?

Mirror polishing is a surface finishing process that produces an extremely smooth, reflective surface by mechanically buffing and grinding metals or other materials. It enhances material aesthetics and corrosion resistance by removing microscopic imperfections and creating a high-gloss, mirror-like finish. Your choice between mirror polished and chemically polished surfaces depends on the desired appearance and application requirements.

What is Chemical Polishing?

Chemical polishing is a metal finishing process that uses a controlled acid or alkaline chemical solution to remove surface material and smooth imperfections at the microscopic level. Unlike mirror polishing, which mainly relies on mechanical abrasion to achieve a reflective surface, chemical polishing enhances corrosion resistance and surface uniformity by selectively dissolving high points on the metal. Your choice between mirror polished and chemically polished finishes depends on desired surface texture, maintenance requirements, and application environment.

Mirror Polished vs Chemically Polished: Key Differences

Mirror polished surfaces exhibit a highly reflective, smooth finish achieved through mechanical abrasion and buffing, enhancing visual appeal and corrosion resistance. Chemically polished surfaces result from controlled acid or chemical treatment that selectively removes metal layers, improving surface uniformity and reducing microscopic roughness without mechanical contact. The key differences lie in the finishing process--mechanical vs. chemical--and resultant texture, with mirror polishing yielding a glossy, reflective surface, while chemical polishing produces a matte or satin finish optimized for precision and cleanliness.

Surface Finish Comparison

Mirror polished surfaces exhibit a high-gloss, reflective finish achieved through mechanical polishing that removes microscopic peaks and valleys, resulting in superior smoothness. Chemically polished finishes rely on controlled chemical etching to smooth and brighten the surface, often producing a less reflective, more uniform matte appearance compared to mirror polishing. Your choice between mirror polished and chemically polished finishes should consider the desired aesthetic and functional application, as mirror polishing offers enhanced reflectivity while chemical polishing provides corrosion resistance with less shine.

Advantages of Mirror Polished Surfaces

Mirror polished surfaces offer superior aesthetic appeal due to their high reflectivity and smooth finish, enhancing product appearance in industries like automotive, aerospace, and luxury goods. These surfaces provide increased corrosion resistance and ease of cleaning, reducing maintenance costs and extending material lifespan. Compared to chemically polished finishes, mirror polishing ensures greater surface uniformity and durability, resulting in improved performance and longer-lasting results in harsh environments.

Benefits of Chemically Polished Surfaces

Chemically polished surfaces offer enhanced corrosion resistance and improved cleanliness due to the removal of surface irregularities and contaminants at a microscopic level. This process results in a more uniform finish that reduces bacterial adhesion, making it ideal for medical and food processing environments. Compared to mirror polishing, chemical polishing requires less manual labor and provides consistent, repeatable results across complex geometries.

Applications in Industry

Mirror polished surfaces are extensively used in industries requiring superior aesthetic appeal and high reflectivity, such as automotive, aerospace, and luxury appliance manufacturing. Chemically polished finishes find significant applications in the pharmaceutical, food processing, and semiconductor industries where enhanced corrosion resistance and smoothness are critical for hygiene and precision. Both techniques improve surface quality but are selected based on specific industry requirements involving durability, cleanliness, and visual standards.

Cost and Efficiency Factors

Mirror polished finishes typically incur higher costs due to the labor-intensive process and specialized equipment required to achieve a high-gloss reflective surface. Chemically polished surfaces offer greater efficiency by reducing processing time and minimizing manual labor, resulting in lower overall production costs. Cost-effectiveness depends on project scale and desired surface quality, with chemical polishing favored for large-volume industrial applications and mirror polishing preferred for premium aesthetic results.

Choosing the Right Polishing Method

Selecting between mirror polished and chemically polished finishes depends on the desired surface quality and application requirements. Mirror polishing produces a highly reflective, smooth surface ideal for aesthetic and sanitary purposes, while chemical polishing provides uniform, corrosion-resistant finishes better suited for complex geometries and industrial components. Consider factors like surface roughness, durability, and cost-efficiency to determine the optimal polishing method for stainless steel or other metal surfaces.

Mirror Polished vs Chemically Polished Infographic

libmatt.com

libmatt.com