Hermetic packaging provides an airtight seal that protects sensitive electronic components from moisture, dust, and other environmental contaminants, ensuring long-term reliability and performance. Non-hermetic packaging, while generally more cost-effective and flexible in design, may expose your devices to external factors that can lead to corrosion or failure over time.

Table of Comparison

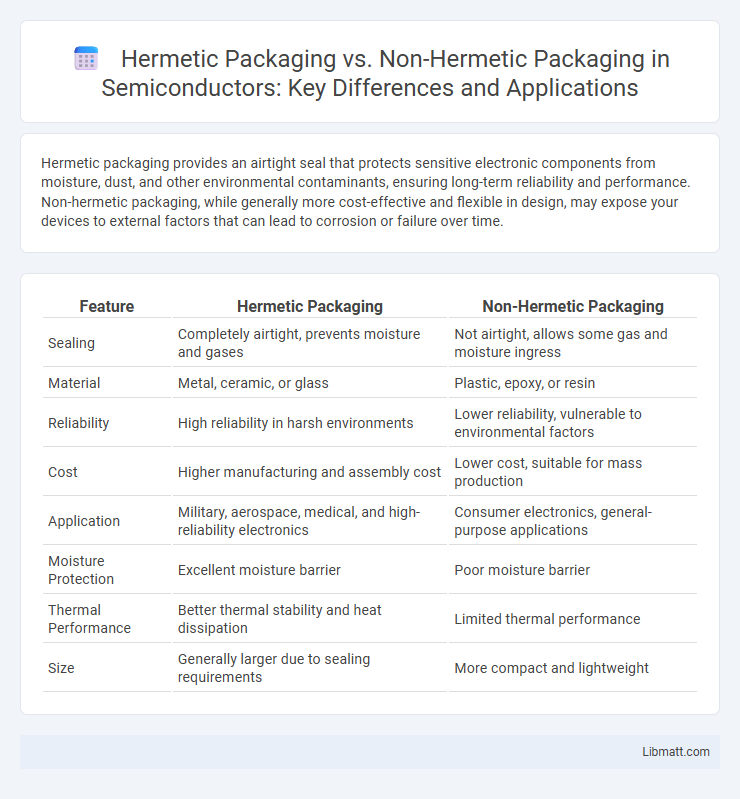

| Feature | Hermetic Packaging | Non-Hermetic Packaging |

|---|---|---|

| Sealing | Completely airtight, prevents moisture and gases | Not airtight, allows some gas and moisture ingress |

| Material | Metal, ceramic, or glass | Plastic, epoxy, or resin |

| Reliability | High reliability in harsh environments | Lower reliability, vulnerable to environmental factors |

| Cost | Higher manufacturing and assembly cost | Lower cost, suitable for mass production |

| Application | Military, aerospace, medical, and high-reliability electronics | Consumer electronics, general-purpose applications |

| Moisture Protection | Excellent moisture barrier | Poor moisture barrier |

| Thermal Performance | Better thermal stability and heat dissipation | Limited thermal performance |

| Size | Generally larger due to sealing requirements | More compact and lightweight |

Introduction to Hermetic and Non-hermetic Packaging

Hermetic packaging ensures a completely sealed environment, protecting sensitive electronic components from moisture, gases, and contaminants, which is crucial for high-reliability applications like aerospace and medical devices. Non-hermetic packaging, while less expensive, allows some environmental exposure and is commonly used for consumer electronics where absolute sealing is not critical. Your choice between hermetic and non-hermetic packaging depends on the level of protection required, device lifespan, and operating conditions.

Key Definitions and Principles

Hermetic packaging refers to a sealing technique that creates an airtight and moisture-proof environment, protecting sensitive electronic components from environmental factors such as humidity, gases, and contaminants. Non-hermetic packaging lacks this airtight seal, offering less protection and making it more vulnerable to deterioration due to exposure to external elements. The primary principle of hermetic packaging is to maintain long-term reliability and device performance by preventing gas and moisture ingress, whereas non-hermetic packaging prioritizes cost-effectiveness and ease of manufacturing at the expense of environmental sealing.

Materials Used in Hermetic Packaging

Hermetic packaging uses materials such as metals (e.g., stainless steel, titanium, and Kovar alloys), ceramics, and glass that provide an airtight and moisture-proof seal essential for protecting sensitive electronic components. These materials exhibit excellent thermal stability, chemical resistance, and impermeability to gases, ensuring long-term reliability in harsh environments. Unlike non-hermetic packaging, which often relies on polymers or plastics prone to moisture ingress, hermetic materials prevent contamination and extend device lifespan.

Materials Used in Non-hermetic Packaging

Non-hermetic packaging commonly utilizes materials such as plastics, epoxy resins, and polyimides that provide flexibility and cost-efficiency but lack airtight sealing properties. These materials are chosen for applications where moisture and gas permeability pose minimal risk to device performance or longevity. Your selection of non-hermetic materials should consider factors like thermal stability, chemical resistance, and environmental exposure to ensure optimal protection and functionality.

Moisture and Environmental Protection

Hermetic packaging provides an airtight seal that effectively prevents moisture ingress, ensuring superior environmental protection for sensitive electronic components and extending their operational lifespan. Non-hermetic packaging, while often more cost-effective, allows limited moisture penetration, which can lead to corrosion, electrical failures, and reduced reliability in harsh environments. Choosing hermetic packaging enhances your product's durability by maintaining a controlled internal atmosphere against moisture and environmental contaminants.

Performance in Extreme Conditions

Hermetic packaging provides superior protection by creating an airtight seal that prevents moisture, gases, and contaminants from entering, ensuring optimal performance in extreme conditions such as high humidity, temperature fluctuations, and corrosive environments. Non-hermetic packaging, lacking this sealed barrier, is more susceptible to environmental damage, resulting in reduced reliability and shorter lifespan under harsh conditions. For your applications requiring durability and consistent performance, especially in aerospace or medical devices, hermetic packaging is the preferred choice.

Applications in Electronics and Other Industries

Hermetic packaging is critical in electronics for protecting sensitive components such as sensors, MEMS devices, and RF modules from moisture, corrosion, and contaminants, ensuring long-term reliability in aerospace, medical implants, and automotive sensors. Non-hermetic packaging, often used in consumer electronics and LED applications, provides cost-effective protection against mechanical damage and moderate environmental exposure but lacks the airtight and moisture barrier properties required for extreme or harsh conditions. Industries like telecommunications and military rely heavily on hermetic sealing to maintain performance under extreme temperatures and pressures, whereas consumer gadgets prioritize non-hermetic solutions for flexibility and lower manufacturing costs.

Cost Comparison and Economic Considerations

Hermetic packaging typically incurs higher initial costs due to specialized materials and sealing processes required to ensure airtight and moisture-proof protection. Non-hermetic packaging offers lower upfront expenses but may lead to increased long-term costs from product degradation, contamination, and reduced shelf life. Economic considerations must balance the higher capital investment in hermetic solutions against potential savings from improved reliability and reduced failure rates in critical applications.

Reliability and Longevity

Hermetic packaging offers superior reliability and longevity by providing an airtight seal that protects electronic components from moisture, contaminants, and environmental stress, thereby preventing corrosion and failure. Non-hermetic packaging, being porous or less sealed, is more susceptible to degradation from humidity and airborne particles, which can shorten device lifespan and reduce operational stability. In high-reliability applications like aerospace and medical devices, hermetic packaging is preferred to ensure consistent performance over extended periods.

Future Trends and Technological Developments

Hermetic packaging continues to evolve with advances in materials like silicon carbide and ceramic composites, enhancing protection against moisture, gases, and extreme temperatures for electronics in aerospace and medical applications. Non-hermetic packaging adopts innovative polymers and conformal coatings that offer cost-effective, flexible sealing solutions for consumer electronics and IoT devices, supporting miniaturization and integration of sensors. Emerging trends highlight the integration of smart packaging with embedded sensors to monitor environmental conditions in real-time, driving improved reliability and lifecycle management in both hermetic and non-hermetic formats.

Hermetic Packaging vs Non-hermetic Packaging Infographic

libmatt.com

libmatt.com