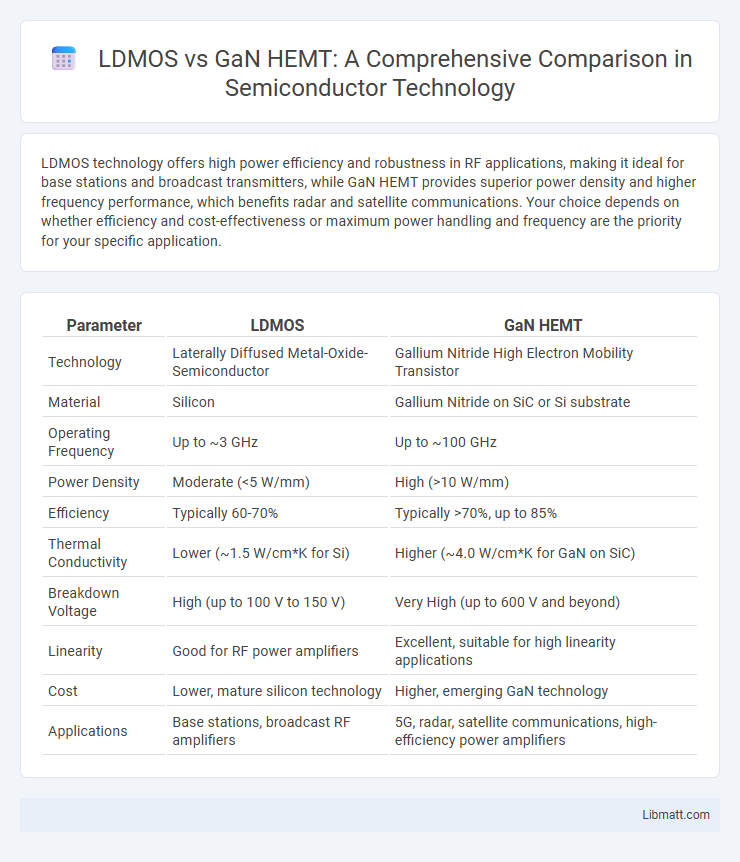

LDMOS technology offers high power efficiency and robustness in RF applications, making it ideal for base stations and broadcast transmitters, while GaN HEMT provides superior power density and higher frequency performance, which benefits radar and satellite communications. Your choice depends on whether efficiency and cost-effectiveness or maximum power handling and frequency are the priority for your specific application.

Table of Comparison

| Parameter | LDMOS | GaN HEMT |

|---|---|---|

| Technology | Laterally Diffused Metal-Oxide-Semiconductor | Gallium Nitride High Electron Mobility Transistor |

| Material | Silicon | Gallium Nitride on SiC or Si substrate |

| Operating Frequency | Up to ~3 GHz | Up to ~100 GHz |

| Power Density | Moderate (<5 W/mm) | High (>10 W/mm) |

| Efficiency | Typically 60-70% | Typically >70%, up to 85% |

| Thermal Conductivity | Lower (~1.5 W/cm*K for Si) | Higher (~4.0 W/cm*K for GaN on SiC) |

| Breakdown Voltage | High (up to 100 V to 150 V) | Very High (up to 600 V and beyond) |

| Linearity | Good for RF power amplifiers | Excellent, suitable for high linearity applications |

| Cost | Lower, mature silicon technology | Higher, emerging GaN technology |

| Applications | Base stations, broadcast RF amplifiers | 5G, radar, satellite communications, high-efficiency power amplifiers |

Introduction to LDMOS and GaN HEMT Technologies

LDMOS (Laterally Diffused Metal-Oxide-Semiconductor) transistors are silicon-based devices widely used in RF power amplifiers for their robustness and cost-effectiveness. GaN HEMT (Gallium Nitride High Electron Mobility Transistor) technology leverages wide bandgap semiconductor properties to achieve higher power density, efficiency, and frequency performance compared to silicon-based LDMOS. GaN HEMTs are increasingly preferred in applications requiring high-frequency, high-power, and high-efficiency operation such as 5G base stations and radar systems.

Basic Operating Principles: LDMOS vs GaN HEMT

LDMOS (Laterally Diffused Metal Oxide Semiconductor) transistors operate by controlling the current flow through a laterally diffused channel within a silicon substrate, offering high gain and efficiency for RF power amplifiers. GaN HEMT (Gallium Nitride High Electron Mobility Transistor) devices leverage a heterojunction between GaN and AlGaN layers to create a high-mobility two-dimensional electron gas, enabling superior electron velocity and breakdown voltage. Understanding these fundamental operating principles helps you select the optimal technology for high-frequency, high-power applications.

Material Properties Comparison

LDMOS (Laterally Diffused Metal Oxide Semiconductor) devices are primarily fabricated on silicon substrates, offering high breakdown voltage and excellent thermal conductivity suitable for high-power RF applications. GaN HEMT (Gallium Nitride High Electron Mobility Transistor) devices leverage the wide bandgap and high electron mobility of GaN material, enabling higher electron saturation velocity, superior power density, and increased efficiency at microwave and millimeter-wave frequencies. The intrinsic material advantages of GaN, including greater electric field strength and thermal stability, surpass silicon-based LDMOS in output power and frequency scaling, making GaN HEMTs ideal for next-generation high-frequency amplifiers.

Frequency Performance: LDMOS vs GaN HEMT

GaN HEMT devices exhibit superior frequency performance compared to LDMOS transistors, offering higher cutoff frequencies (f_T) often exceeding 100 GHz, while LDMOS generally operates effectively below 10 GHz. The high electron mobility and wide bandgap of GaN enable faster switching speeds and lower parasitic capacitances, making GaN HEMTs ideal for microwave and millimeter-wave applications. LDMOS remains advantageous in lower-frequency, high-power scenarios due to its robustness and cost-effectiveness but falls short in ultra-high-frequency efficiency and gain.

Power Efficiency and Output

LDMOS transistors excel in power efficiency and high output for RF power applications, delivering reliable performance in base station amplifiers. GaN HEMT devices offer superior power density and higher breakdown voltage, enabling greater power efficiency and output in compact, high-frequency systems. Your choice depends on whether you prioritize cost-effective, proven LDMOS technology or the advanced efficiency and power capabilities of GaN HEMTs for demanding applications.

Thermal Management and Reliability

LDMOS devices typically offer better thermal conductivity and robustness, enabling efficient heat dissipation and superior reliability under high-power operations. GaN HEMT devices, while exhibiting higher power density and efficiency, require advanced thermal management solutions like heat sinks and thermal interface materials to prevent hotspot formation and ensure long-term reliability. Optimizing Your system's cooling strategy is crucial when choosing between LDMOS and GaN HEMT for high-performance applications.

Cost and Manufacturing Differences

LDMOS technology benefits from lower manufacturing costs due to its use of mature silicon-based processes and widespread industry adoption, making it more economical for high-volume production. GaN HEMT devices, while offering superior performance in high-frequency and high-power applications, involve higher fabrication costs stemming from complex epitaxial growth on expensive substrates such as SiC or sapphire. The cost disparity also arises from GaN's lower manufacturing yield and less established production infrastructure compared to the well-optimized LDMOS supply chain.

Applications in RF and Power Electronics

LDMOS technology excels in RF power amplifiers for base stations due to its high linearity and cost-effectiveness, while GaN HEMT devices dominate in high-frequency and high-power applications like radar and satellite communications because of superior electron mobility and thermal conductivity. In power electronics, GaN HEMTs enable higher efficiency and miniaturization in DC-DC converters and electric vehicle inverters, outperforming LDMOS in switching speed and thermal management. Your choice between LDMOS and GaN HEMT depends on application-specific requirements for frequency, power density, and efficiency.

Longevity and Device Lifetime

LDMOS transistors typically offer longer device lifetimes due to their mature silicon-based technology and robust thermal performance, making them suitable for high-reliability applications. GaN HEMTs, while achieving higher power densities and efficiency, experience accelerated degradation mechanisms under high electric fields and temperature stress, potentially limiting their longevity. Device lifetime in GaN technology continues to improve with advances in material quality and packaging, but LDMOS remains the benchmark for established, long-term reliability in RF power amplifiers.

Future Trends in LDMOS and GaN HEMT Development

Future trends in LDMOS technology emphasize improvements in power density, breakdown voltage, and cost efficiency to support expanding 5G infrastructure and advanced radar systems. GaN HEMT development focuses on achieving higher electron mobility, increased thermal conductivity, and enhanced linearity to enable next-generation high-frequency applications and electric vehicle powertrains. Integration of GaN HEMTs with advanced packaging and wide bandgap substrates is expected to accelerate their adoption in both commercial and defense sectors.

LDMOS vs GaN HEMT Infographic

libmatt.com

libmatt.com