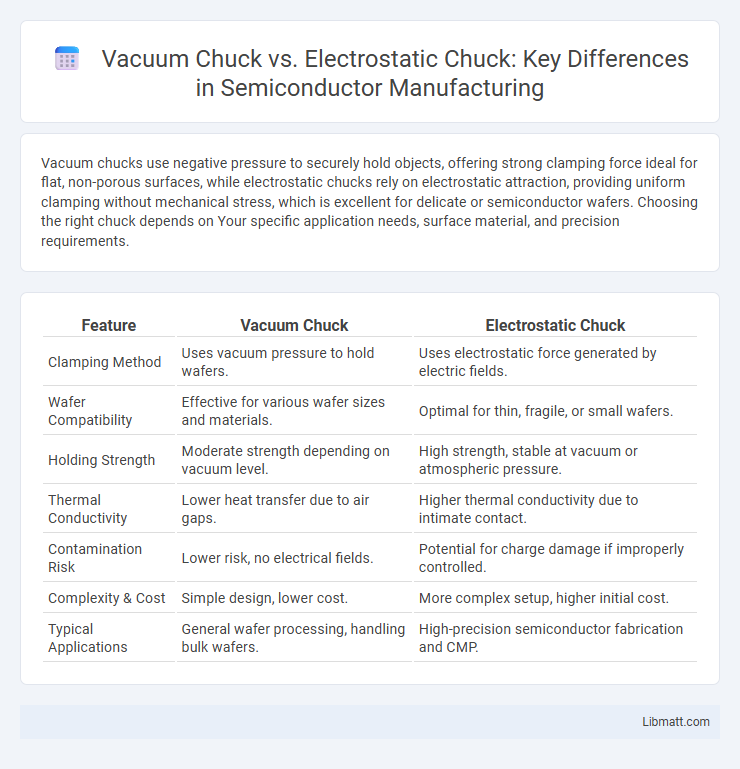

Vacuum chucks use negative pressure to securely hold objects, offering strong clamping force ideal for flat, non-porous surfaces, while electrostatic chucks rely on electrostatic attraction, providing uniform clamping without mechanical stress, which is excellent for delicate or semiconductor wafers. Choosing the right chuck depends on Your specific application needs, surface material, and precision requirements.

Table of Comparison

| Feature | Vacuum Chuck | Electrostatic Chuck |

|---|---|---|

| Clamping Method | Uses vacuum pressure to hold wafers. | Uses electrostatic force generated by electric fields. |

| Wafer Compatibility | Effective for various wafer sizes and materials. | Optimal for thin, fragile, or small wafers. |

| Holding Strength | Moderate strength depending on vacuum level. | High strength, stable at vacuum or atmospheric pressure. |

| Thermal Conductivity | Lower heat transfer due to air gaps. | Higher thermal conductivity due to intimate contact. |

| Contamination Risk | Lower risk, no electrical fields. | Potential for charge damage if improperly controlled. |

| Complexity & Cost | Simple design, lower cost. | More complex setup, higher initial cost. |

| Typical Applications | General wafer processing, handling bulk wafers. | High-precision semiconductor fabrication and CMP. |

Introduction to Workholding Technologies

Vacuum chucks use suction to secure workpieces by creating a pressure differential, offering strong holding force for flat or slightly irregular surfaces in semiconductor and precision machining applications. Electrostatic chucks employ Coulombic attraction through charged electrodes to hold wafers firmly, ensuring minimal mechanical stress and optimal thermal conductivity in microfabrication. Both technologies enhance positioning accuracy and reduce workpiece distortion, but selection depends on factors like material type, process temperature, and required holding strength.

What is a Vacuum Chuck?

A vacuum chuck is a device that secures workpieces using negative pressure created by suction, making it ideal for holding flat or smooth surfaces firmly during machining or inspection. It provides uniform clamping force without mechanical stress, ensuring precision and reducing the risk of damage to delicate components. Your choice of a vacuum chuck can enhance stability and accuracy in manufacturing processes requiring gentle yet reliable workpiece retention.

What is an Electrostatic Chuck?

An electrostatic chuck is a device used to securely hold semiconductor wafers during manufacturing by generating an electrostatic force that clamps the wafer without physical pressure. Unlike vacuum chucks that rely on suction to maintain grip, electrostatic chucks offer uniform wafer holding, reducing particle contamination and mechanical damage. Your choice between these chucks depends on the specific application requirements, such as wafer size, sensitive material handling, and process precision.

Core Principles of Vacuum vs Electrostatic Chucks

Vacuum chucks operate by creating a pressure differential, where air is evacuated from a sealed cavity to generate a strong holding force on the workpiece, relying on mechanical suction principles. Electrostatic chucks use electrostatic forces generated by applying high voltage to create Coulombic attraction between the chuck surface and the substrate, enabling secure, non-mechanical clamping. The core principle difference lies in vacuum chucks utilizing physical pressure gradients for retention, while electrostatic chucks depend on electric field-induced adhesion for precise and contamination-free holding.

Applications in Precision Manufacturing

Vacuum chucks are widely used in precision manufacturing for holding flat, non-porous materials such as glass, silicon wafers, and metal sheets, providing reliable grip through suction force ideal for machining and inspection processes. Electrostatic chucks offer superior clamping for delicate or thin substrates like semiconductor wafers, utilizing electrostatic attraction to maintain uniform hold without mechanical stress. Your choice between vacuum and electrostatic chucks depends on the material properties and sensitivity required in microelectronics fabrication and precision component assembly.

Advantages of Vacuum Chucks

Vacuum chucks offer strong gripping force through negative pressure, ensuring precise and stable workpiece holding during machining or inspection processes. They perform effectively on a variety of materials and surface textures, providing versatility that suits many industrial applications. Your choice of a vacuum chuck enhances reliability and reduces the risk of slippage, leading to improved accuracy and consistent results.

Advantages of Electrostatic Chucks

Electrostatic chucks offer superior holding force compared to vacuum chucks, enabling precise and stable wafer handling during semiconductor manufacturing. They provide uniform clamping pressure without requiring a vacuum source, reducing contamination risks and improving process cleanliness. Their ability to operate effectively at high temperatures makes them ideal for advanced lithography and etching processes.

Limitations and Challenges

Vacuum chucks face limitations such as difficulty in maintaining uniform suction on porous or uneven surfaces, leading to possible workpiece damage or slippage during machining. Electrostatic chucks present challenges including sensitivity to surface contamination and humidity, which can reduce their holding force and reliability. Your material compatibility and environmental conditions play a crucial role in selecting between these chuck types.

Key Selection Factors

Vacuum chucks provide high holding force by creating suction through a vacuum seal, ideal for applications requiring robust mechanical grip on non-conductive or porous materials. Electrostatic chucks use electrostatic forces to securely hold conductive or semiconductor substrates with minimal particle generation, making them suitable for precision wafer handling in semiconductor manufacturing. Your choice depends on factors such as material type, surface flatness, operating environment, and contamination sensitivity to ensure optimal performance and reliability.

Conclusion: Choosing the Right Chuck Technology

Selecting the right chuck technology depends on your specific application requirements, such as material type, temperature tolerance, and wafer size. Vacuum chucks offer strong holding force for smooth surfaces but may struggle with porous or delicate substrates, while electrostatic chucks provide uniform clamping with minimal mechanical stress, ideal for advanced semiconductor fabrication. Your choice should balance precision, reliability, and operational conditions to optimize manufacturing efficiency and product quality.

Vacuum Chuck vs Electrostatic Chuck Infographic

libmatt.com

libmatt.com