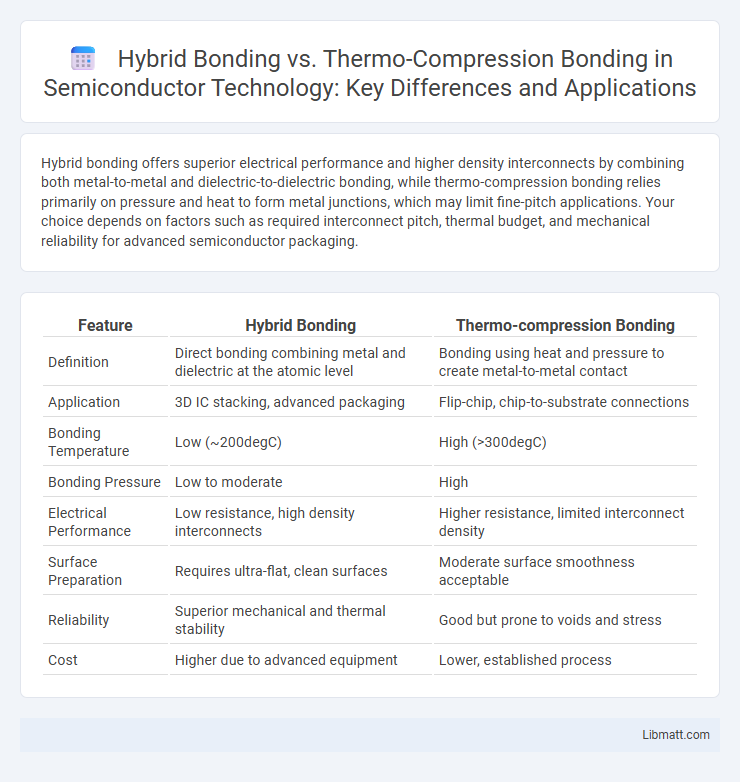

Hybrid bonding offers superior electrical performance and higher density interconnects by combining both metal-to-metal and dielectric-to-dielectric bonding, while thermo-compression bonding relies primarily on pressure and heat to form metal junctions, which may limit fine-pitch applications. Your choice depends on factors such as required interconnect pitch, thermal budget, and mechanical reliability for advanced semiconductor packaging.

Table of Comparison

| Feature | Hybrid Bonding | Thermo-compression Bonding |

|---|---|---|

| Definition | Direct bonding combining metal and dielectric at the atomic level | Bonding using heat and pressure to create metal-to-metal contact |

| Application | 3D IC stacking, advanced packaging | Flip-chip, chip-to-substrate connections |

| Bonding Temperature | Low (~200degC) | High (>300degC) |

| Bonding Pressure | Low to moderate | High |

| Electrical Performance | Low resistance, high density interconnects | Higher resistance, limited interconnect density |

| Surface Preparation | Requires ultra-flat, clean surfaces | Moderate surface smoothness acceptable |

| Reliability | Superior mechanical and thermal stability | Good but prone to voids and stress |

| Cost | Higher due to advanced equipment | Lower, established process |

Introduction to Wafer Bonding Technologies

Wafer bonding technologies, including hybrid bonding and thermo-compression bonding, play a crucial role in semiconductor device fabrication by enabling the integration of heterogeneous materials with high precision. Hybrid bonding combines dielectric and metal bonds, offering low-resistance electrical interconnects and superior mechanical strength without requiring high temperatures. Thermo-compression bonding relies on heat and pressure to form metallic bonds, providing reliable connections but often necessitating elevated temperatures that can impact sensitive device layers.

Defining Hybrid Bonding

Hybrid bonding combines direct oxide bonding with metal-metal bonding, typically copper-to-copper, enabling fine pitch interconnections below 1 micron. Unlike thermo-compression bonding, which relies on heat and pressure to deform metals for adhesion, hybrid bonding forms robust atomic bonds without significant thermal expansion issues. This technology enhances electrical performance and mechanical reliability, crucial for advanced semiconductor packaging and 3D integration.

Overview of Thermo-compression Bonding

Thermo-compression bonding involves using elevated temperature and pressure to create a strong metallic or semiconductor bond at the interface of two substrates, typically in microelectronics packaging. This process ensures high electrical conductivity and mechanical strength by promoting atomic diffusion and plastic deformation at the bonding surfaces. Compared to hybrid bonding, thermo-compression bonding demands precise control of temperature and pressure to prevent damage while achieving reliable metallurgical bonds.

Key Process Differences

Hybrid bonding integrates dielectric and metal bonding simultaneously at room temperature, enabling direct copper-to-copper connections with minimal thermal budget. Thermo-compression bonding relies on applying heat and pressure to align and bond metal surfaces, typically requiring higher temperatures to achieve atomic diffusion and mechanical adhesion. Hybrid bonding offers finer pitch alignment and reduced processing complexity, whereas thermo-compression bonding is traditionally used for robust metal-to-metal interfaces but demands more stringent thermal management.

Material Compatibility and Surface Preparation

Hybrid bonding excels in material compatibility by enabling direct bonding between copper and low-k dielectrics with minimal thermal budget, enhancing device performance and scalability. Surface preparation for hybrid bonding requires ultra-flat, contaminant-free surfaces achieved through chemical-mechanical polishing (CMP) and plasma activation to ensure atomic-level contact. Thermo-compression bonding relies on deformable metal interlayers like gold or copper, necessitating higher temperatures and pressures for solid-state diffusion, with surface preparation focusing on removing oxides and contaminants to enable strong metallurgical bonds.

Bonding Strength and Reliability

Hybrid bonding offers superior bonding strength and reliability compared to thermo-compression bonding due to its direct oxide-to-oxide and metal-to-metal atomic interface, resulting in enhanced mechanical stability and lower interface resistance. Thermo-compression bonding relies on high temperature and pressure to create metal interdiffusion, which can lead to increased residual stress and potential reliability issues under thermal cycling. The atomic-level bonding in hybrid bonding significantly reduces void formation and improves long-term device performance in advanced semiconductor packaging.

Electrical and Thermal Performance

Hybrid bonding offers superior electrical performance due to direct copper-to-copper interconnects, minimizing resistance and enhancing signal integrity in high-speed applications. It also improves thermal conductivity by enabling efficient heat dissipation through tightly bonded interfaces, crucial for advanced semiconductor devices. Thermo-compression bonding, while adequate for certain uses, generally exhibits higher electrical resistance and less effective heat transfer because of the interposing materials and bonding pressures required.

Integration with Advanced Packaging

Hybrid bonding enables ultra-fine pitch interconnections and higher density integration by combining metal and dielectric bonding, which enhances signal integrity and reduces parasitic capacitance in advanced packaging. Thermo-compression bonding relies on pressure and heat to form metal-to-metal bonds, offering robust mechanical strength but limiting scaling due to larger bond pitch and potential thermal stress. Hybrid bonding facilitates 3D integration and heterogeneous stacking in cutting-edge semiconductor packages, supporting developments like chiplets and wafer-level packaging more effectively than thermo-compression bonding.

Scalability and Manufacturing Challenges

Hybrid bonding offers superior scalability due to its ability to create fine-pitch interconnections below 1 micron, facilitating higher density integration in advanced semiconductor packaging. Thermo-compression bonding, while reliable for larger pitch applications, faces significant manufacturing challenges such as stringent temperature and pressure control, which limit its scalability for next-generation devices. The precise alignment and uniform pressure distribution required in thermo-compression bonding increase process complexity and reduce throughput compared to the more scalable and automatable hybrid bonding techniques.

Future Trends in 3D IC Bonding Techniques

Future trends in 3D IC bonding techniques highlight Hybrid Bonding as a key innovation due to its ability to provide ultra-fine pitch interconnections, improved electrical performance, and higher density integration compared to Thermo-compression Bonding. Thermo-compression remains valuable for its reliability and well-established process but faces limitations in scaling for next-generation devices, pushing the industry towards hybrid approaches that combine fine direct metal-to-metal bonding with low thermal budgets. Your choice of bonding method will increasingly depend on the specific performance, integration density, and cost trade-offs demanded by advanced semiconductor applications.

Hybrid Bonding vs Thermo-compression Bonding Infographic

libmatt.com

libmatt.com