A blanking die is designed for cutting out blank shapes from material sheets without any prior electrical testing, while a known good die (KGD) refers to a semiconductor die that has passed rigorous electrical and functional tests to ensure it meets performance standards. You should choose a known good die when reliability and performance are critical for your application, whereas blanking dies are primarily used for initial shaping and material preparation.

Table of Comparison

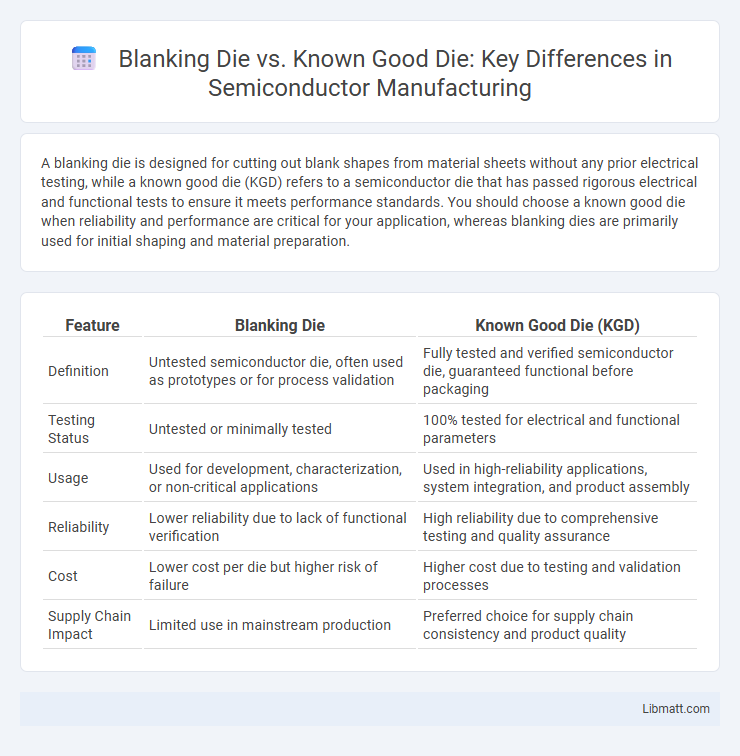

| Feature | Blanking Die | Known Good Die (KGD) |

|---|---|---|

| Definition | Untested semiconductor die, often used as prototypes or for process validation | Fully tested and verified semiconductor die, guaranteed functional before packaging |

| Testing Status | Untested or minimally tested | 100% tested for electrical and functional parameters |

| Usage | Used for development, characterization, or non-critical applications | Used in high-reliability applications, system integration, and product assembly |

| Reliability | Lower reliability due to lack of functional verification | High reliability due to comprehensive testing and quality assurance |

| Cost | Lower cost per die but higher risk of failure | Higher cost due to testing and validation processes |

| Supply Chain Impact | Limited use in mainstream production | Preferred choice for supply chain consistency and product quality |

Introduction to Blanking Die and Known Good Die

Blanking die refers to a specialized stamping tool used in manufacturing to cut or shape material by removing a portion of the workpiece, often utilized in metal fabrication processes. Known good die (KGD) signifies a semiconductor die that has been tested and verified to meet all functional and performance specifications before being used in assembly to ensure reliability. Understanding the roles and quality assurance of blanking die and known good die is critical for optimizing production efficiency and product integrity in industrial and semiconductor applications.

Definition of Blanking Die

Blanking Die is a precision manufacturing tool used to cut or blank out a specific shape from a sheet of material, often metal, with high accuracy and consistency. It forms the initial stage in semiconductor production or metal fabrications where the individual die or components are separated for further processing. Your choice of using Blanking Die impacts the quality and efficiency of producing Known Good Die, which are tested and verified functional semiconductor units.

Definition of Known Good Die

A Known Good Die (KGD) refers to an individual semiconductor die that has been tested and verified to function correctly before packaging. Unlike blanking dies, which are untested or raw semiconductor dies, KGDs have passed electrical and functional tests to ensure reliability and performance. Using KGDs in multi-chip modules or system-in-package designs improves yield and reduces the risk of device failure.

Key Differences Between Blanking Die and Known Good Die

Blanking Die is a manufacturing tool designed to stamp precise shapes from raw materials, ensuring consistent component dimensions, while Known Good Die refers to a verified, defect-free die used as a quality benchmark in production. The key difference lies in their application: Blanking Die actively shapes parts during fabrication, whereas Known Good Die serves as a reference to detect flaws and maintain production accuracy. Your production line benefits from using Known Good Dies by reducing errors and improving overall product reliability compared to relying solely on Blanking Dies without validation.

Manufacturing Processes: Blanking Die vs Known Good Die

Blanking Die manufacturing involves precise stamping techniques to cut raw materials into specific shapes, ensuring consistent dimensional accuracy for initial component formation. Known Good Die (KGD) processes emphasize rigorous testing and validation steps, confirming that each die meets quality standards and functions flawlessly before integration. Your production efficiency depends on balancing the high-volume capabilities of blanking dies with the reliability assurance offered by Known Good Dies.

Applications of Blanking Die

Blanking dies are essential in manufacturing for precisely cutting sheet metal into specific shapes, commonly used in automotive, aerospace, and electronics industries to produce components like brackets, enclosures, and connectors. These dies enhance efficiency and accuracy during mass production, ensuring consistent part quality and material utilization. Your production process benefits from blanking dies by streamlining sheet metal preparation before further machining or assembly, contrasting with Known Good Dies, which verify die performance rather than perform cutting.

Applications of Known Good Die

Known Good Die (KGD) is critical in semiconductor packaging, used to ensure only fully tested, defect-free dies are integrated into multi-chip modules and stacked die configurations. KGD application improves yield and reliability in complex assemblies such as 3D ICs, system-in-package (SiP), and wafer-level packaging. This approach reduces costs related to testing and rework by eliminating defective dies before final assembly.

Advantages and Disadvantages Comparison

Blanking Die offers higher precision in producing consistent die profiles, which improves manufacturing efficiency but may require more initial investment and maintenance compared to Known Good Die (KGD). KGD ensures reliability by verifying die functionality before integration, reducing the risk of faults in your final product but can result in higher testing costs and longer lead times. Balancing these factors depends on your production scale and quality standards, with Blanking Die suited for mass production and KGD ideal for high-reliability applications.

Cost Implications of Each Die Type

Blanking Dies typically offer lower initial costs due to simpler design and manufacturing processes, making them suitable for high-volume production with standardized parts. Known Good Dies, while more expensive upfront because they require extensive testing and verification to ensure defect-free quality, reduce long-term costs by minimizing scrap rates and rework. Your decision between these die types should consider the balance between upfront investment and potential savings from improved yield and reliability.

Choosing Between Blanking Die and Known Good Die

Choosing between a blanking die and a known good die depends on production requirements and quality control priorities. Blanking dies are ideal for high-volume manufacturing due to their efficiency in cutting raw material into uniform blanks, whereas known good dies ensure higher reliability by using pre-tested, defect-free components for precision assembly. Evaluating cost, yield rates, and failure risks guides manufacturers in selecting the most suitable die type for their semiconductor or electronics assembly process.

Blanking Die vs Known Good Die Infographic

libmatt.com

libmatt.com