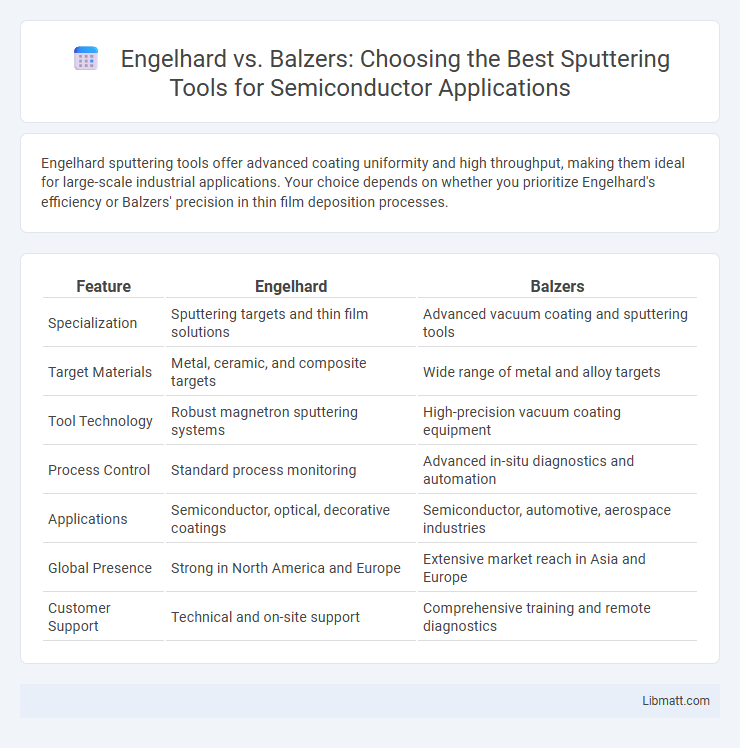

Engelhard sputtering tools offer advanced coating uniformity and high throughput, making them ideal for large-scale industrial applications. Your choice depends on whether you prioritize Engelhard's efficiency or Balzers' precision in thin film deposition processes.

Table of Comparison

| Feature | Engelhard | Balzers |

|---|---|---|

| Specialization | Sputtering targets and thin film solutions | Advanced vacuum coating and sputtering tools |

| Target Materials | Metal, ceramic, and composite targets | Wide range of metal and alloy targets |

| Tool Technology | Robust magnetron sputtering systems | High-precision vacuum coating equipment |

| Process Control | Standard process monitoring | Advanced in-situ diagnostics and automation |

| Applications | Semiconductor, optical, decorative coatings | Semiconductor, automotive, aerospace industries |

| Global Presence | Strong in North America and Europe | Extensive market reach in Asia and Europe |

| Customer Support | Technical and on-site support | Comprehensive training and remote diagnostics |

Introduction to Sputtering Targets

Sputtering targets are critical components in thin-film deposition processes used in semiconductor manufacturing and optics, where materials are atomistically ejected to coat substrates. Engelhard and Balzers offer specialized sputtering targets, with Engelhard known for high-purity metal targets and Balzers recognized for advanced coating technology compatibility. Understanding your application's material requirements ensures selecting the optimal target type, maximizing film quality and deposition efficiency.

Overview of Engelhard as a Sputtering Target Supplier

Engelhard, a leading supplier in the sputtering target industry, excels in providing high-purity metals and alloys tailored for thin film deposition processes. Renowned for advanced material science innovations, Engelhard delivers sputtering targets with superior consistency and minimal contamination, optimizing coating uniformity and adhesion. Their comprehensive product range supports applications in semiconductor manufacturing, data storage, and optical coatings, reflecting a strong commitment to quality and technological advancement.

Balzers: Company Profile and Expertise

Balzers, a leading name in the sputtering tools industry, specializes in advanced coating technologies that enhance the durability and performance of thin films used in various applications. With decades of expertise, Balzers offers innovative PVD (Physical Vapor Deposition) and sputtering solutions known for exceptional precision, uniformity, and material versatility. Your projects benefit from Balzers' commitment to quality and cutting-edge research, making it a preferred partner for high-performance sputtering tool needs.

Material Range and Purity Comparison

Engelhard sputtering targets offer a broad material range including precious metals, alloys, and ceramics with purity levels typically exceeding 99.99%, ensuring superior film quality for advanced semiconductor and optical applications. Balzers specializes in high-purity metallic sputtering targets, particularly for noble metals and specialized alloys, maintaining purity standards above 99.995% to optimize deposition performance and minimize contamination. Both manufacturers deliver high-purity materials, but Balzers focuses more on ultra-high purity and precision-engineered alloys, whereas Engelhard provides a wider selection of material compositions suited for diverse industrial coatings.

Sputtering Performance: Engelhard vs Balzers

Engelhard and Balzers sputtering tools differ significantly in sputtering performance, with Engelhard offering high-density coatings and superior adhesion properties ideal for industrial applications. Balzers excels in uniform thin film deposition, providing precision and consistency crucial for semiconductor manufacturing. Both brands optimize target utilization, but Engelhard's advanced magnetron designs deliver higher sputtering rates and durability under aggressive operating conditions.

Customization Capabilities and Services

Engelhard offers extensive customization capabilities for sputtering tools, tailoring target materials and compositions to meet specific industrial needs, enhancing film properties and process efficiency. Balzers provides highly specialized coating solutions with flexible system configurations, enabling precision adjustments for unique substrate requirements and complex layer structures. Both companies emphasize responsive service support, ensuring optimal performance through tailored equipment modifications and on-site technical assistance.

Pricing Structure and Value Proposition

Engelhard and Balzers offer distinct pricing structures for their sputtering tools, with Engelhard typically providing bundled packages that include integrated system components, leading to higher upfront costs but comprehensive solutions. Balzers focuses on modular pricing, allowing You to select specific components, resulting in more flexible investment options tailored to your production needs. The value proposition of Engelhard lies in turnkey systems with optimized performance, while Balzers emphasizes customization and scalability, enabling cost-efficiency aligned with evolving sputtering applications.

Reliability and Quality Control Standards

Engelhard and Balzers lead the sputtering tools industry with rigorous reliability and quality control standards, ensuring consistent deposition performance and minimal tool downtime. Engelhard implements advanced in-situ monitoring and statistical process control to maintain uniform thin film properties, while Balzers emphasizes ISO-certified quality management systems and real-time diagnostics for defect reduction. Both companies prioritize high material purity and precision engineering, resulting in superior sputtering targets and coating uniformity crucial for semiconductor and optical applications.

Industry Applications and Customer Feedback

Engelhard and Balzers sputtering tools are extensively used across semiconductor manufacturing, data storage, and optical coatings, with Engelhard favored for its precise thin-film deposition in microelectronics and Balzers valued for high-quality surface functionalization in medical devices. Customer feedback highlights Engelhard's reliability in producing ultra-thin, uniform films vital for advanced chip fabrication, while Balzers receives praise for its consistent coating performance and strong technical support. Your choice depends on specific industry requirements, balancing Engelhard's expertise in advanced electronics with Balzers' strength in versatile, high-durability coatings.

Conclusion: Selecting Between Engelhard and Balzers

Choosing between Engelhard and Balzers sputtering tools depends heavily on specific application requirements such as coating uniformity, target material compatibility, and deposition rates. Engelhard offers robust equipment with established performance in high-volume manufacturing, while Balzers excels in precision and advanced control features suitable for research and niche coatings. Your decision should weigh operational efficiency, maintenance support, and cost-effectiveness to optimize thin film deposition outcomes.

Engelhard vs Balzers (for sputtering tools) Infographic

libmatt.com

libmatt.com