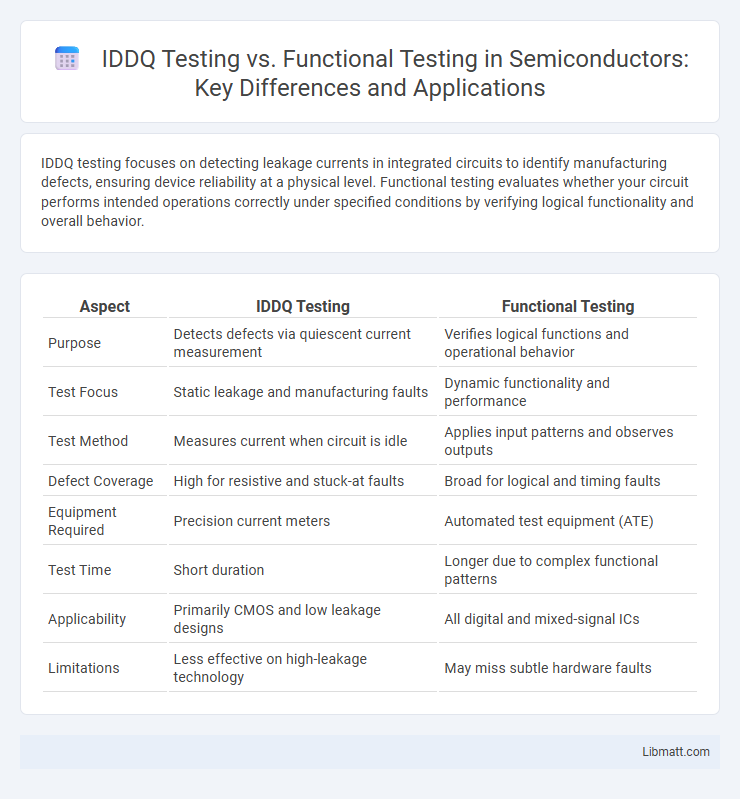

IDDQ testing focuses on detecting leakage currents in integrated circuits to identify manufacturing defects, ensuring device reliability at a physical level. Functional testing evaluates whether your circuit performs intended operations correctly under specified conditions by verifying logical functionality and overall behavior.

Table of Comparison

| Aspect | IDDQ Testing | Functional Testing |

|---|---|---|

| Purpose | Detects defects via quiescent current measurement | Verifies logical functions and operational behavior |

| Test Focus | Static leakage and manufacturing faults | Dynamic functionality and performance |

| Test Method | Measures current when circuit is idle | Applies input patterns and observes outputs |

| Defect Coverage | High for resistive and stuck-at faults | Broad for logical and timing faults |

| Equipment Required | Precision current meters | Automated test equipment (ATE) |

| Test Time | Short duration | Longer due to complex functional patterns |

| Applicability | Primarily CMOS and low leakage designs | All digital and mixed-signal ICs |

| Limitations | Less effective on high-leakage technology | May miss subtle hardware faults |

Introduction to Semiconductor Testing

IDDQ testing measures the quiescent current in a semiconductor device to detect manufacturing defects such as gate oxide shorts and leakage paths that are often undetectable by functional testing. Functional testing verifies the logical operation of a chip by applying input patterns and checking the corresponding output responses against expected behavior. Combining IDDQ testing with functional testing enhances fault coverage by identifying both parametric and functional defects in semiconductor devices.

Overview of IDDQ Testing

IDDQ testing is a semiconductor test technique that measures the quiescent power supply current to identify manufacturing defects in integrated circuits. Unlike functional testing, which verifies the logical operation of a device, IDDQ testing detects subtle defects such as gate oxide shorts and leakage currents by analyzing current consumption during idle states. This method enhances fault coverage and reliability by pinpointing defects that may not cause functional test failures but can lead to long-term operational issues.

Overview of Functional Testing

Functional testing evaluates a system's operational behavior against specified requirements by validating input-output processes and user interactions. It ensures that your software performs expected tasks correctly under various conditions without delving into internal code structures. This testing method complements IDDQ testing, which focuses on detecting manufacturing faults at the hardware level by measuring quiescent current.

Key Differences Between IDDQ and Functional Testing

IDDQ testing measures the quiescent supply current to identify defects in integrated circuits by detecting abnormal leakage currents, ensuring hardware reliability at the transistor level. Functional testing verifies that the overall system or device operates according to its specified functions by applying input vectors and observing outputs under normal operating conditions. Your choice between IDDQ and functional testing depends on whether the goal is to detect manufacturing faults at the transistor level or validate correct behavior of the complete digital system.

Advantages of IDDQ Testing

IDDQ testing offers high sensitivity in detecting manufacturing defects by measuring the quiescent supply current, enabling early identification of faults such as gate oxide shorts and leakage paths that functional testing might miss. This technique improves yield and reliability by catching defects during the production phase, reducing costly field failures and ensuring robust circuit performance. IDDQ testing is particularly effective for CMOS technology where low static current makes deviations easier to detect compared to relying solely on logical output verification in functional tests.

Benefits of Functional Testing

Functional testing verifies that software applications perform according to specified requirements, ensuring user satisfaction and system reliability. It identifies defects related to user interface, APIs, databases, security, and functionality, thereby enhancing the overall quality of the product. This testing approach supports better risk management by validating real-world usage scenarios and reducing costly post-release failures.

Limitations of IDDQ Testing

IDDQ testing faces limitations such as sensitivity to process variations, which can cause false positives, and its ineffectiveness in detecting defects that do not affect quiescent current. This method is less suitable for lower voltage and advanced technology nodes where leakage currents increase naturally. You should complement IDDQ testing with functional testing to ensure comprehensive defect coverage and accurate fault detection.

Limitations of Functional Testing

Functional testing evaluates software behavior against requirements but often misses subtle hardware defects like leakage currents that IDDQ testing detects. These undetected leakage currents can cause power inefficiencies and reliability issues, which functional testing alone cannot address. Incorporating IDDQ testing complements your quality assurance by identifying such hidden physical faults.

When to Choose IDDQ Testing vs Functional Testing

Choose IDDQ testing when identifying manufacturing defects like gate oxide shorts and leakage currents is critical, especially in advanced CMOS technologies where low power consumption and reliability are priorities. Functional testing is preferred for verifying that your device performs its intended operations under normal conditions, detecting logical errors and functional failures effectively. Combining both methods enhances overall quality assurance by addressing both physical defects and functional correctness.

Future Trends in Semiconductor Testing

IDDQ testing will become increasingly vital for identifying leakage currents in advanced semiconductor nodes, where power efficiency and device reliability are critical. Functional testing continues to evolve with AI-driven methods to enhance fault detection and accelerate test times, ensuring higher yield in complex integrated circuits. Your semiconductor testing strategy must integrate both techniques to address emerging challenges in nanoscale device fabrication and ensure future-proof quality assurance.

IDDQ Testing vs Functional Testing Infographic

libmatt.com

libmatt.com