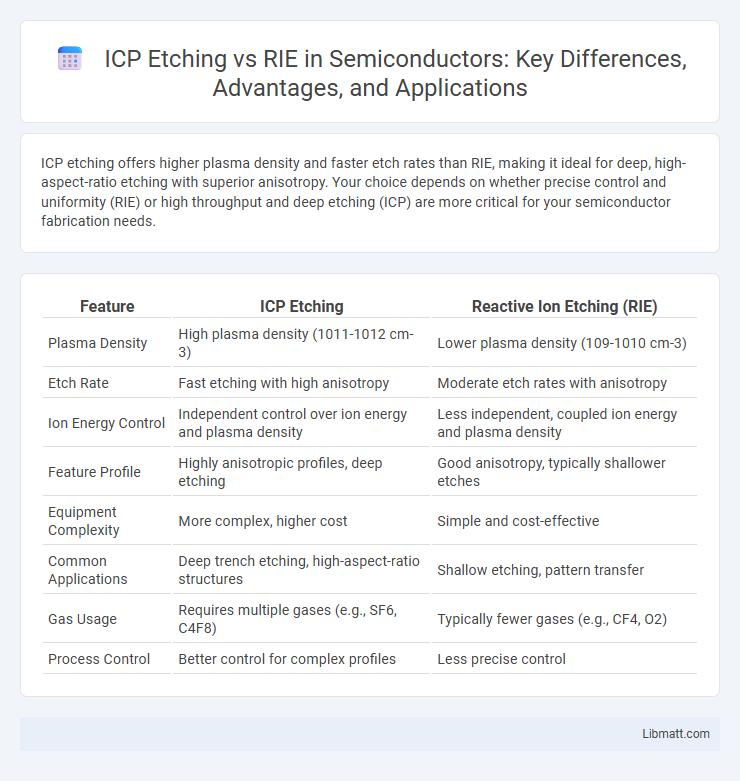

ICP etching offers higher plasma density and faster etch rates than RIE, making it ideal for deep, high-aspect-ratio etching with superior anisotropy. Your choice depends on whether precise control and uniformity (RIE) or high throughput and deep etching (ICP) are more critical for your semiconductor fabrication needs.

Table of Comparison

| Feature | ICP Etching | Reactive Ion Etching (RIE) |

|---|---|---|

| Plasma Density | High plasma density (1011-1012 cm-3) | Lower plasma density (109-1010 cm-3) |

| Etch Rate | Fast etching with high anisotropy | Moderate etch rates with anisotropy |

| Ion Energy Control | Independent control over ion energy and plasma density | Less independent, coupled ion energy and plasma density |

| Feature Profile | Highly anisotropic profiles, deep etching | Good anisotropy, typically shallower etches |

| Equipment Complexity | More complex, higher cost | Simple and cost-effective |

| Common Applications | Deep trench etching, high-aspect-ratio structures | Shallow etching, pattern transfer |

| Gas Usage | Requires multiple gases (e.g., SF6, C4F8) | Typically fewer gases (e.g., CF4, O2) |

| Process Control | Better control for complex profiles | Less precise control |

Introduction to Plasma Etching: ICP vs RIE

ICP etching and RIE are advanced plasma etching techniques used in semiconductor fabrication for precise material removal. ICP (Inductively Coupled Plasma) etching provides high-density plasma and independent control of ion energy and ion flux, resulting in high etch rates with excellent anisotropy. RIE (Reactive Ion Etching) offers directional etching through combined chemical and physical mechanisms, making it suitable for fine feature pattern transfer, and your choice depends on the desired etch profile and material selectivity.

Fundamental Principles of ICP and RIE

ICP etching employs inductively coupled plasma to generate a high-density ion environment, enabling precise and anisotropic material removal with high etch rates and low ion energy damage. RIE, or reactive ion etching, relies on a combination of chemical reactions and physical ion bombardment within a low-density plasma, offering greater control over etch profiles and selectivity but typically with lower etch rates. Understanding these fundamental principles helps you select the optimal etching method based on desired etch rate, anisotropy, and substrate sensitivity.

Equipment Design Differences

ICP etching utilizes a high-density plasma source generated by inductively coupled coils, allowing independent control of ion density and ion energy, which improves etch uniformity and rate. In contrast, RIE equipment employs a capacitively coupled plasma system where ion density and energy are interdependent, often resulting in lower plasma density and slower etch rates. The ICP reactor features separate RF power supplies for plasma generation and wafer biasing, whereas RIE systems typically use a single RF power source, limiting process flexibility and precision.

Process Mechanisms: Ionization and Etching

ICP etching utilizes inductively coupled plasma to generate a high-density ionized gas, enhancing ionization efficiency and enabling deeper, faster etching with excellent anisotropy. RIE combines reactive ion species generated by capacitively coupled plasma with physical ion bombardment, allowing precise control of etching directionality but typically at lower plasma densities. Your choice between ICP and RIE impacts ionization levels and etching uniformity, with ICP favoring higher ion densities and RIE offering refined directional etching control.

Etch Rate Comparison

ICP etching offers significantly higher etch rates compared to RIE due to its high-density plasma source, which enhances ion flux and energy at the substrate surface. RIE typically provides lower etch rates but allows for better anisotropy and selectivity control, making it suitable for delicate microfabrication tasks. The optimized ion energy and plasma density in ICP lead to faster material removal, improving throughput in semiconductor manufacturing processes.

Profile Control and Anisotropy

ICP etching offers superior profile control and high anisotropy due to its high-density plasma and independent control of ion energy and density, enabling precise vertical sidewalls in microfabrication. In contrast, RIE provides moderate anisotropy with less plasma density, often resulting in slightly tapered profiles and less refined etch selectivity. ICP's advanced ability to tailor etch parameters makes it the preferred technique for achieving highly anisotropic and well-defined etch profiles in complex semiconductor device structures.

Substrate Damage and Selectivity

ICP etching offers higher ion density and lower ion energy, resulting in reduced substrate damage compared to RIE, which employs higher energy ions that can cause more surface damage. ICP provides superior selectivity due to better control over etching parameters and anisotropy, enabling finer tuning between the mask and substrate materials. Your choice between ICP and RIE should consider the sensitivity of the substrate and the desired precision in material removal.

Applications in Semiconductor Manufacturing

ICP etching offers high-density plasma and independent control of ion energy, making it ideal for deep, high-aspect-ratio features in semiconductor manufacturing such as through-silicon vias and MEMS devices. RIE provides more isotropic etching with precise control suited for shallow, planar etch processes like pattern transfer in photolithography and dielectric layer etching. Your choice depends on device architecture requirements, with ICP favored for complex 3D structures and RIE for uniform surface etching.

Advantages and Limitations of ICP and RIE

ICP etching offers high plasma density and independent control of ion energy and density, enabling deep, anisotropic etching with excellent selectivity, but tends to be more complex and costly than RIE systems. RIE provides simpler operation with moderate plasma density suitable for fine patterning in microfabrication, though it may suffer from slower etch rates and less control over ion energy, potentially limiting precision. Your choice depends on etching depth, material selectivity, and budget constraints, as ICP excels in high-aspect-ratio etching while RIE is effective for shallower, less demanding processes.

Choosing the Right Etching Technology

Selecting the appropriate etching technology depends on the desired etch profile, precision, and material compatibility. Inductively Coupled Plasma (ICP) etching offers high plasma density and enhanced anisotropy, making it ideal for deep etching and complex pattern transfer in semiconductor fabrication. Reactive Ion Etching (RIE) provides better control over ion energy, suitable for shallow etching and applications requiring minimal substrate damage.

ICP Etching vs RIE Infographic

libmatt.com

libmatt.com