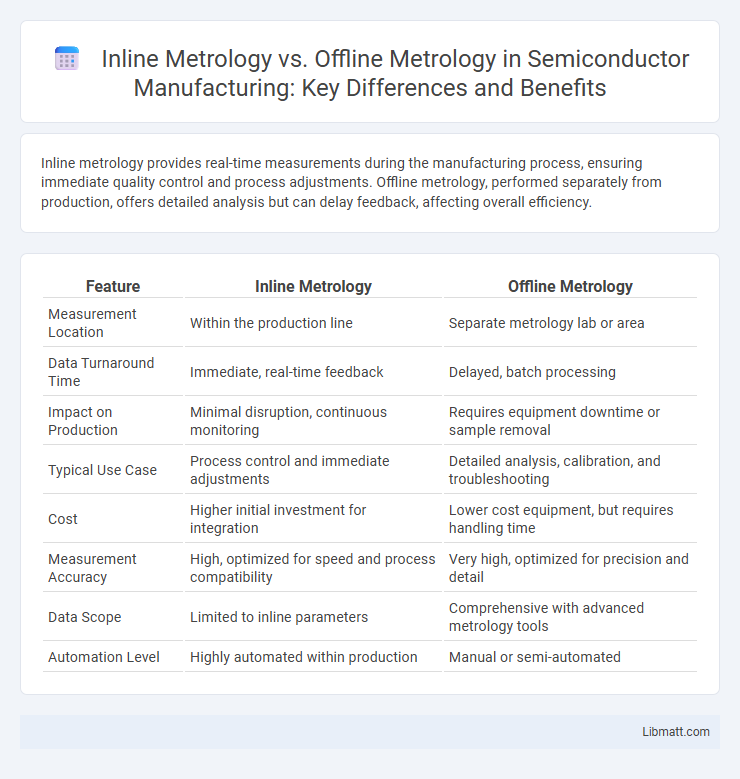

Inline metrology provides real-time measurements during the manufacturing process, ensuring immediate quality control and process adjustments. Offline metrology, performed separately from production, offers detailed analysis but can delay feedback, affecting overall efficiency.

Table of Comparison

| Feature | Inline Metrology | Offline Metrology |

|---|---|---|

| Measurement Location | Within the production line | Separate metrology lab or area |

| Data Turnaround Time | Immediate, real-time feedback | Delayed, batch processing |

| Impact on Production | Minimal disruption, continuous monitoring | Requires equipment downtime or sample removal |

| Typical Use Case | Process control and immediate adjustments | Detailed analysis, calibration, and troubleshooting |

| Cost | Higher initial investment for integration | Lower cost equipment, but requires handling time |

| Measurement Accuracy | High, optimized for speed and process compatibility | Very high, optimized for precision and detail |

| Data Scope | Limited to inline parameters | Comprehensive with advanced metrology tools |

| Automation Level | Highly automated within production | Manual or semi-automated |

Introduction to Inline and Offline Metrology

Inline metrology integrates measurement tools directly into the production line, enabling real-time data collection and immediate quality control. Offline metrology involves measuring components separately from the manufacturing process, often requiring additional time for analysis. Your choice between inline and offline metrology impacts production efficiency and accuracy based on the application's speed and precision requirements.

Key Differences Between Inline and Offline Metrology

Inline metrology involves real-time measurement and inspection integrated directly into the production process, enabling immediate identification of defects and process variations. Offline metrology, by contrast, occurs separately from the manufacturing line, requiring samples to be transported to specialized measurement equipment, often resulting in delayed feedback. Key differences include the speed and frequency of data collection, with inline systems providing continuous monitoring while offline systems offer higher precision but less immediate data.

Advantages of Inline Metrology

Inline metrology offers real-time process monitoring, enabling immediate detection and correction of manufacturing deviations that significantly reduces waste and downtime. By integrating sensors directly into the production line, inline metrology ensures continuous quality control and higher throughput without interrupting workflows. This approach improves yield predictability and accelerates decision-making compared to traditional offline metrology methods that rely on periodic, post-process inspections.

Benefits of Offline Metrology

Offline metrology offers the benefit of comprehensive and detailed analysis without interrupting production processes, allowing you to perform accurate measurements in a controlled environment. It enables flexibility in scheduling inspections and reduces the risk of contaminating or disrupting sensitive manufacturing lines. These advantages lead to improved data reliability and enhanced product quality assurance.

Accuracy and Precision: A Comparative Analysis

Inline metrology provides real-time measurement accuracy by integrating sensors directly into the production line, reducing variations caused by environmental changes and handling errors commonly seen in offline metrology. Offline metrology, while often offering higher precision through controlled laboratory conditions and advanced instruments, introduces delays and potential sample degradation during transfer. Your choice depends on whether immediate feedback (inline) or highly controlled, precise measurements (offline) align best with your quality control requirements.

Speed and Throughput Considerations

Inline metrology offers real-time measurement and analysis directly within the production line, significantly enhancing speed and throughput by eliminating delays associated with sample transport and setup. Offline metrology, while often more precise, requires batch processing and manual handling, which can slow overall production flow and reduce throughput. Optimizing your process with inline metrology can accelerate decision-making and improve yield by providing immediate feedback during manufacturing.

Integration with Manufacturing Processes

Inline metrology integrates directly with manufacturing processes, allowing real-time measurement and immediate feedback to optimize production efficiency and quality control. Offline metrology operates separately from production lines, requiring manual sampling and analysis, which can delay identification of defects and process adjustments. For Your manufacturing setup, inline metrology offers seamless data flow and faster decision-making, crucial for high-speed or automated environments.

Cost Implications: Inline vs Offline

Inline metrology reduces long-term costs by enabling real-time process monitoring, minimizing scrap rates, and preventing costly production downtime. Offline metrology often involves higher labor and equipment expenses due to separate measurement steps and potential delays in feedback loops. Your choice between inline and offline metrology should consider both immediate capital investment and the ongoing operational savings associated with each approach.

Application Scenarios and Industry Use Cases

Inline metrology provides real-time measurement and quality control during manufacturing, making it ideal for high-volume production lines in semiconductor, automotive, and electronics industries where immediate feedback ensures process optimization. Offline metrology is suited for detailed analysis, calibration, and troubleshooting in industries such as aerospace and medical device manufacturing, where accuracy and comprehensive testing are crucial but can be performed outside the production flow. Your choice between inline and offline metrology depends on whether your application requires continuous, real-time monitoring or periodic, in-depth measurement for quality assurance and product development.

Choosing the Right Metrology Approach for Your Needs

Inline metrology provides real-time measurement data directly integrated into the manufacturing process, enabling immediate detection and correction of deviations to improve production efficiency and yield. Offline metrology offers high-precision, comprehensive analysis typically performed in a controlled environment, ideal for detailed quality control and validation of complex components. Selecting the right metrology approach depends on factors such as production speed, accuracy requirements, cost constraints, and the specific application's need for immediate feedback versus thorough post-process inspection.

Inline Metrology vs Offline Metrology Infographic

libmatt.com

libmatt.com