An interposer serves as a physical and electrical interface that routes signals between different semiconductor components, enhancing communication and integration in multi-chip modules. Your choice between an interposer and a bridge die depends on factors like signal integrity, thermal management, and packaging complexity in your advanced electronic designs.

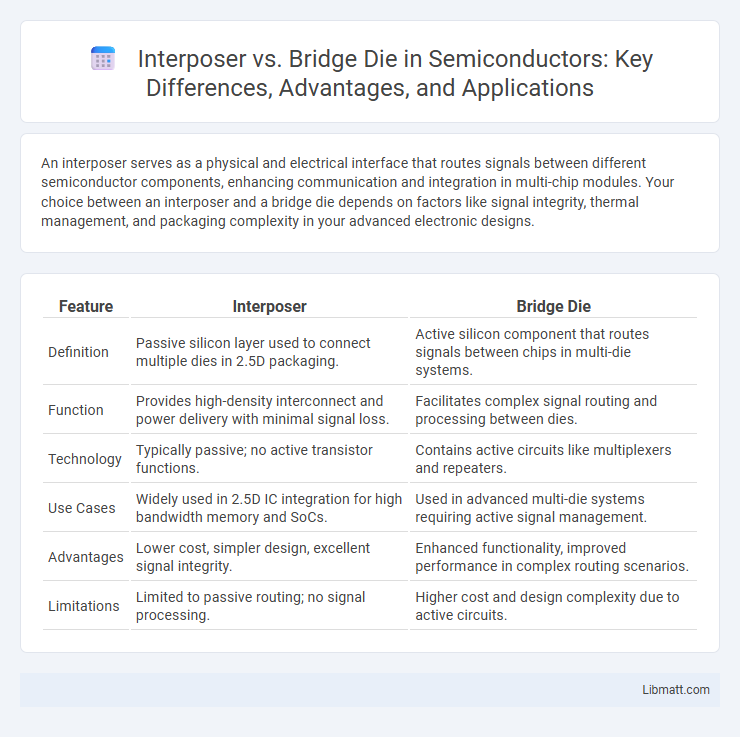

Table of Comparison

| Feature | Interposer | Bridge Die |

|---|---|---|

| Definition | Passive silicon layer used to connect multiple dies in 2.5D packaging. | Active silicon component that routes signals between chips in multi-die systems. |

| Function | Provides high-density interconnect and power delivery with minimal signal loss. | Facilitates complex signal routing and processing between dies. |

| Technology | Typically passive; no active transistor functions. | Contains active circuits like multiplexers and repeaters. |

| Use Cases | Widely used in 2.5D IC integration for high bandwidth memory and SoCs. | Used in advanced multi-die systems requiring active signal management. |

| Advantages | Lower cost, simpler design, excellent signal integrity. | Enhanced functionality, improved performance in complex routing scenarios. |

| Limitations | Limited to passive routing; no signal processing. | Higher cost and design complexity due to active circuits. |

Introduction to Interposer and Bridge Die

An interposer serves as a high-density substrate that facilitates electrical connections between semiconductor dies, enhancing signal integrity and reducing latency in advanced packaging. Bridge die acts as an intermediary component that connects multiple chiplets, enabling component integration and heterogeneous system designs. Both technologies are crucial in 2.5D and 3D IC packaging for improving performance and miniaturization.

What is an Interposer?

An interposer is a crucial component in advanced semiconductor packaging, serving as an intermediary layer that electrically connects a chip to a substrate or another chip, enabling high-density integration and improved signal integrity. Unlike a bridge die, which actively manages signal routing between different dies, an interposer primarily provides passive wiring and redistribution of connections with minimal active circuitry. Your choice of an interposer can significantly enhance performance in multi-chip modules and 2.5D IC architectures by facilitating tighter interconnect pitch and reduced latency.

What is a Bridge Die?

A Bridge Die is a specialized semiconductor component used to connect two or more chiplets within a package, enhancing performance and reducing latency by enabling direct communication paths. Unlike traditional interposers, which serve as passive substrates for routing electrical signals, Bridge Dies actively manage signal integrity and power distribution across chiplets. Your system benefits from a Bridge Die's compact, high-bandwidth interconnect architecture that supports advanced multi-die integration technologies like 2.5D and 3D ICs.

Key Differences Between Interposer and Bridge Die

Interposers serve as passive substrates that facilitate high-density electrical connections between chips in advanced packaging, primarily enabling 2.5D integration through silicon, organic, or glass materials. Bridge dies are active semiconductor components embedded within multi-chip modules to manage signal routing, power distribution, or logic functions, often found in advanced 3D integrated circuits. The key difference lies in interposers being primarily passive platforms providing physical and electrical connectivity, while bridge dies actively process or modify signals and power within the package.

Use Cases: When to Use Interposer vs Bridge Die

Interposers are ideal for high-density integration and advanced packaging in applications like HPC and AI accelerators, where signal integrity and bandwidth are critical. Bridge dies suit scenarios requiring cost-effective interconnects between heterogeneous dies in 2.5D packages, often used in consumer electronics and mid-range computing devices. Your choice depends on performance needs, complexity, and budget constraints of the target application.

Performance Implications

Interposer technology offers lower latency and higher signal integrity by providing a shorter, more direct path between components compared to bridge die solutions. Bridge dies, while useful for integrating heterogeneous elements, can introduce additional signal delay and power consumption due to their larger footprint and more complex routing. Optimizing your system choice depends on balancing performance needs with design constraints, where interposers excel in high-frequency, low-latency applications.

Cost Considerations

Interposers typically incur higher manufacturing costs due to complex fabrication processes involving silicon or organic materials with fine-pitch routing capabilities. Bridge die solutions often present a cost-effective alternative by simplifying integration between chiplets without extensive redistribution layers, reducing overall expenses. Evaluating your design requirements against these cost factors helps determine the most economical approach for multi-chip packaging.

Integration and Manufacturing Complexity

Interposers enable high-density integration by providing a silicon or organic layer that connects multiple dies with fine-pitch interconnects, but they introduce significant manufacturing complexity due to precise alignment and advanced lithography techniques. Bridge dies, used primarily in fan-out wafer-level packaging, simplify stacking by acting as intermediary connectors with lower complexity, yet may limit integration density compared to interposers. Your choice between interposer and bridge die technologies depends on balancing integration demands against manufacturing capabilities and cost.

Industry Applications and Trends

Interposers and bridge dies serve critical roles in advanced semiconductor packaging, with interposers predominantly used in high-performance computing, AI accelerators, and bandwidth-intensive applications thanks to their ability to enable dense interconnects and heterogeneous integration. Bridge dies offer efficient die-to-die connectivity in 3D packaging solutions, finding growing adoption in mobile devices, edge computing, and automotive electronics where space constraints and thermal management are essential. Your choice between interposer and bridge die technologies should align with the specific industry requirements for speed, power efficiency, and integration complexity, reflecting major trends toward miniaturization and increased system functionality.

Future Outlook: Interposer vs Bridge Die Technologies

Interposer and bridge die technologies both play crucial roles in advancing semiconductor packaging, with interposers enabling high-density, high-bandwidth interconnections and bridge dies offering flexible scalability for heterogeneous integration. The future outlook points towards increased adoption of bridge die solutions due to their cost-effectiveness and compatibility with advanced nodes, while interposers remain vital for ultra-high-performance applications in AI and HPC systems. Your choice between these technologies should consider evolving industry trends, performance requirements, and integration complexity.

Interposer vs Bridge Die Infographic

libmatt.com

libmatt.com