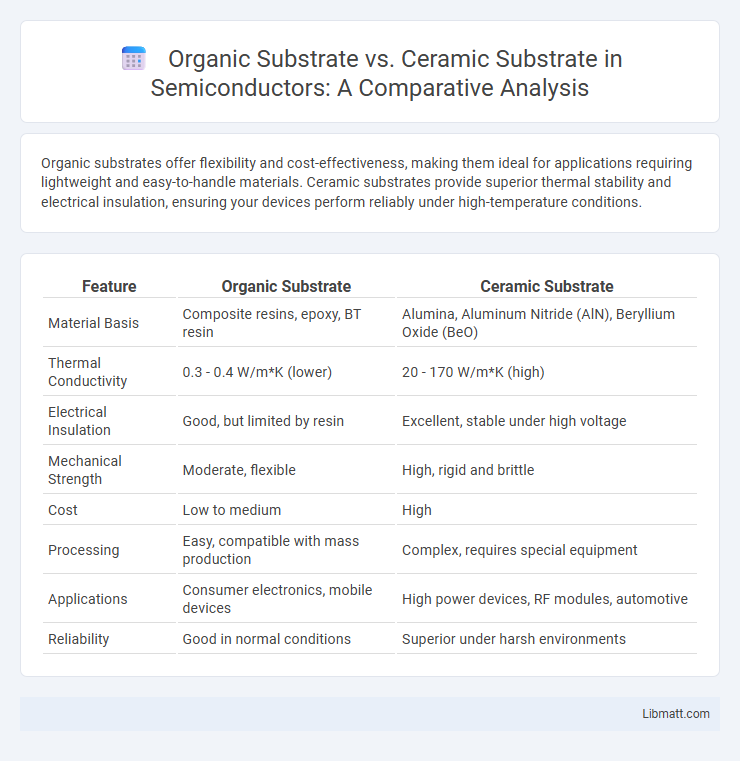

Organic substrates offer flexibility and cost-effectiveness, making them ideal for applications requiring lightweight and easy-to-handle materials. Ceramic substrates provide superior thermal stability and electrical insulation, ensuring your devices perform reliably under high-temperature conditions.

Table of Comparison

| Feature | Organic Substrate | Ceramic Substrate |

|---|---|---|

| Material Basis | Composite resins, epoxy, BT resin | Alumina, Aluminum Nitride (AlN), Beryllium Oxide (BeO) |

| Thermal Conductivity | 0.3 - 0.4 W/m*K (lower) | 20 - 170 W/m*K (high) |

| Electrical Insulation | Good, but limited by resin | Excellent, stable under high voltage |

| Mechanical Strength | Moderate, flexible | High, rigid and brittle |

| Cost | Low to medium | High |

| Processing | Easy, compatible with mass production | Complex, requires special equipment |

| Applications | Consumer electronics, mobile devices | High power devices, RF modules, automotive |

| Reliability | Good in normal conditions | Superior under harsh environments |

Introduction to Electronic Substrates

Electronic substrates serve as foundational materials for mounting and interconnecting electronic components, influencing device performance and reliability. Organic substrates, typically made from materials like FR4 or BT resin, offer flexibility, cost-efficiency, and ease of manufacturing for consumer electronics and mobile devices. Ceramic substrates, composed of materials such as alumina or aluminum nitride, provide superior thermal conductivity, electrical insulation, and mechanical strength, making them ideal for high-power and high-frequency applications.

What is an Organic Substrate?

An organic substrate is a high-performance printed circuit board (PCB) foundation made from composite materials such as fiberglass-reinforced epoxy resin, designed to provide excellent electrical insulation and thermal management. It offers lightweight, flexibility, and cost-effective manufacturing suited for various electronic applications, especially in LEDs and automotive lighting. Unlike ceramic substrates, organic substrates have lower thermal conductivity but superior mechanical adaptability for complex circuit designs.

What is a Ceramic Substrate?

A ceramic substrate is a solid base material made primarily from inorganic, non-metallic ceramics such as alumina, aluminum nitride, or silicon carbide, known for excellent electrical insulation and thermal conductivity. It provides a stable platform for electronic components, ensuring efficient heat dissipation and durability in high-temperature environments, crucial in power electronics and LED manufacturing. Compared to organic substrates, ceramic substrates offer superior mechanical strength, chemical resistance, and longer operational lifespan under harsh conditions.

Key Material Properties: Organic vs Ceramic

Organic substrates exhibit lower thermal conductivity and reduced heat resistance compared to ceramic substrates, making them less suitable for high-temperature applications. Ceramic substrates provide superior insulation, high thermal stability, and excellent mechanical strength, which enhances device reliability in demanding environments. The dielectric constant of ceramic materials is typically lower, improving signal integrity and performance in electronic circuits compared to organic substrates.

Thermal Performance Comparison

Ceramic substrates exhibit superior thermal conductivity, often exceeding 20 W/m*K, facilitating efficient heat dissipation in high-power electronic devices. Organic substrates typically have lower thermal conductivity, ranging from 0.3 to 1.0 W/m*K, which can limit performance in thermal-intensive applications. The enhanced thermal performance of ceramic substrates reduces thermal resistance, improving device reliability and lifespan in demanding operational environments.

Electrical Performance Considerations

Organic substrates offer lower electrical conductivity and are prone to higher signal loss due to their dielectric properties, making them less ideal for high-frequency applications. Ceramic substrates provide superior electrical insulation, low dielectric constant, and minimal signal attenuation, enhancing performance in RF and microwave circuits. The thermal stability and low dielectric loss tangent of ceramic substrates also contribute to improved signal integrity and faster electrical switching speeds.

Cost and Manufacturing Differences

Organic substrates are generally lower in cost due to cheaper raw materials such as fiberglass or paper-based composites, making them suitable for cost-sensitive applications. Ceramic substrates, while more expensive, offer superior thermal conductivity and durability, resulting from high-temperature sintering processes involving alumina or aluminum nitride powders. Manufacturing organic substrates is faster and involves less complex processing steps compared to ceramic substrates, which require precision firing and grinding to achieve exact specifications and performance standards.

Applications and Industry Uses

Organic substrates are widely used in consumer electronics, automotive, and LED lighting due to their cost-effectiveness and flexibility in circuit board applications. Ceramic substrates are preferred in high-power and high-frequency industries such as aerospace, defense, and medical devices because of their superior thermal conductivity and electrical insulation properties. Both materials serve critical functions in semiconductor packaging, with ceramics supporting high-reliability applications and organics enabling mass production of lightweight, compact electronics.

Pros and Cons: Organic Substrate

Organic substrates offer advantages such as lower production costs and excellent electrical insulation properties, making them ideal for consumer electronics. Their flexibility and lightweight nature enhance design versatility, but they typically have lower thermal conductivity and reduced heat resistance compared to ceramic substrates. Your choice depends on whether cost efficiency and flexibility outweigh the need for high thermal performance in your application.

Pros and Cons: Ceramic Substrate

Ceramic substrates offer superior thermal stability and excellent electrical insulation, making them ideal for high-temperature applications and electronic circuits. Their brittle nature and higher manufacturing costs are significant drawbacks compared to organic substrates, which are more flexible and cost-effective. Ceramic substrates also provide better chemical resistance but can be heavier and less adaptable for intricate designs.

Organic Substrate vs Ceramic Substrate Infographic

libmatt.com

libmatt.com