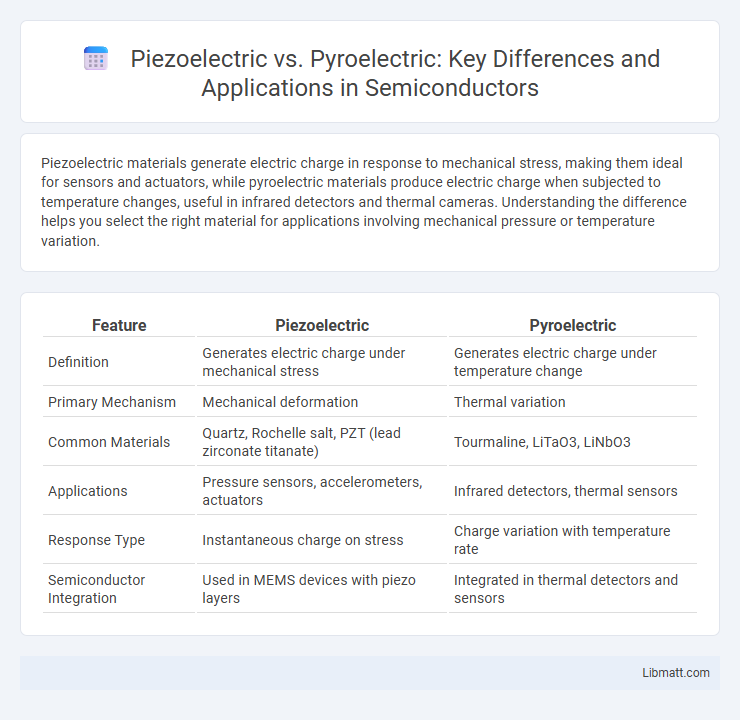

Piezoelectric materials generate electric charge in response to mechanical stress, making them ideal for sensors and actuators, while pyroelectric materials produce electric charge when subjected to temperature changes, useful in infrared detectors and thermal cameras. Understanding the difference helps you select the right material for applications involving mechanical pressure or temperature variation.

Table of Comparison

| Feature | Piezoelectric | Pyroelectric |

|---|---|---|

| Definition | Generates electric charge under mechanical stress | Generates electric charge under temperature change |

| Primary Mechanism | Mechanical deformation | Thermal variation |

| Common Materials | Quartz, Rochelle salt, PZT (lead zirconate titanate) | Tourmaline, LiTaO3, LiNbO3 |

| Applications | Pressure sensors, accelerometers, actuators | Infrared detectors, thermal sensors |

| Response Type | Instantaneous charge on stress | Charge variation with temperature rate |

| Semiconductor Integration | Used in MEMS devices with piezo layers | Integrated in thermal detectors and sensors |

Introduction to Piezoelectric and Pyroelectric Materials

Piezoelectric materials generate electric charge in response to mechanical stress, making them essential for sensors, actuators, and energy harvesting devices. Pyroelectric materials produce an electric charge when subjected to temperature changes, which is critical for infrared detectors and thermal sensors. Both materials belong to the broader class of ferroelectrics but differ in their response stimuli--mechanical versus thermal--enabling diverse applications in electronics and material science.

Fundamental Principles: How Piezoelectricity Works

Piezoelectricity arises from the mechanical deformation of certain crystalline materials, which generates an electric charge due to the displacement of electric dipoles within their crystal lattice. This effect occurs when stress or pressure is applied, causing a shift in charge centers and resulting in a voltage across the material. The fundamental distinction from pyroelectricity lies in the direct conversion of mechanical energy into electrical energy, whereas pyroelectricity is driven by temperature fluctuations influencing spontaneous polarization.

Understanding Pyroelectricity: The Basics

Pyroelectricity refers to the ability of certain materials to generate an electric charge in response to temperature changes, distinguishing it from piezoelectricity, which is driven by mechanical stress. These pyroelectric materials exhibit spontaneous polarization that varies with temperature fluctuations, creating a temporary voltage. Understanding pyroelectricity helps you optimize applications like infrared sensors and thermal imaging by leveraging temperature-induced electric responses.

Key Differences Between Piezoelectric and Pyroelectric Effects

Piezoelectric materials generate electric charge in response to mechanical stress, while pyroelectric materials produce electric charge due to temperature changes. The piezoelectric effect is associated with pressure or deformation, making it ideal for sensors and actuators, whereas the pyroelectric effect is temperature-dependent and commonly used in infrared detectors and thermal sensors. Understanding these distinct mechanisms helps you select the right material for applications requiring mechanical energy conversion or thermal energy detection.

Common Materials Exhibiting Piezoelectricity

Quartz, Rochelle salt, and lead zirconate titanate (PZT) are common materials exhibiting piezoelectricity, widely used in sensors and actuators. These materials generate an electric charge in response to mechanical stress, making them essential in medical ultrasound devices, electronic frequency generation, and precision actuators. Understanding the properties of these materials can help you select the right piezoelectric component for your application.

Typical Pyroelectric Materials and Their Properties

Typical pyroelectric materials include lithium tantalate (LiTaO3), triglycine sulfate (TGS), and polyvinylidene fluoride (PVDF), each exhibiting strong spontaneous polarization changes with temperature fluctuations. These materials possess high pyroelectric coefficients, enabling efficient conversion of thermal variations into electrical signals, crucial for infrared sensors and thermal imaging devices. Your selection of a pyroelectric material depends on factors like temperature range, sensitivity, and stability for optimizing performance in temperature-sensing applications.

Applications of Piezoelectric Materials in Industry

Piezoelectric materials find extensive applications in industry, including precision sensors, actuators, and energy harvesting devices due to their ability to convert mechanical stress into electrical signals. They are widely used in ultrasonic transducers, medical imaging equipment, and vibration monitoring systems, enhancing product performance and reliability. Your industrial processes can benefit from piezoelectric technology by improving automation, quality control, and real-time monitoring capabilities.

Pyroelectric Materials: Uses and Innovations

Pyroelectric materials, which generate an electrical charge in response to temperature changes, are widely utilized in infrared sensors, thermal imaging, and energy harvesting devices. Innovations in pyroelectric ceramics and polymers have enhanced their sensitivity and stability, enabling advanced applications in medical diagnostics and environmental monitoring. Your next project can benefit from these materials' unique ability to convert thermal variations directly into electrical signals, driving efficiency in smart sensor technology.

Advantages and Limitations: Piezoelectric vs Pyroelectric

Piezoelectric materials excel in converting mechanical stress into electrical energy, making them ideal for sensors and actuators with high sensitivity and durability, but their effectiveness diminishes under static pressure. Pyroelectric materials generate electrical charges in response to temperature changes, offering advantages in thermal sensing applications, yet their performance is limited by environmental temperature stability and lower energy conversion efficiency. Your choice between piezoelectric and pyroelectric depends on whether mechanical vibrations or thermal fluctuations dominate your application's environment.

Future Trends and Research in Electroactive Materials

Future trends in electroactive materials emphasize the development of multifunctional devices combining piezoelectric and pyroelectric properties for enhanced energy harvesting and sensing applications. Research is advancing toward nanostructured materials and flexible substrates to improve sensitivity, durability, and integration in wearable and IoT devices. Emerging studies focus on lead-free compositions and environmentally sustainable materials to meet regulatory demands and promote broader commercial adoption.

Piezoelectric vs Pyroelectric Infographic

libmatt.com

libmatt.com