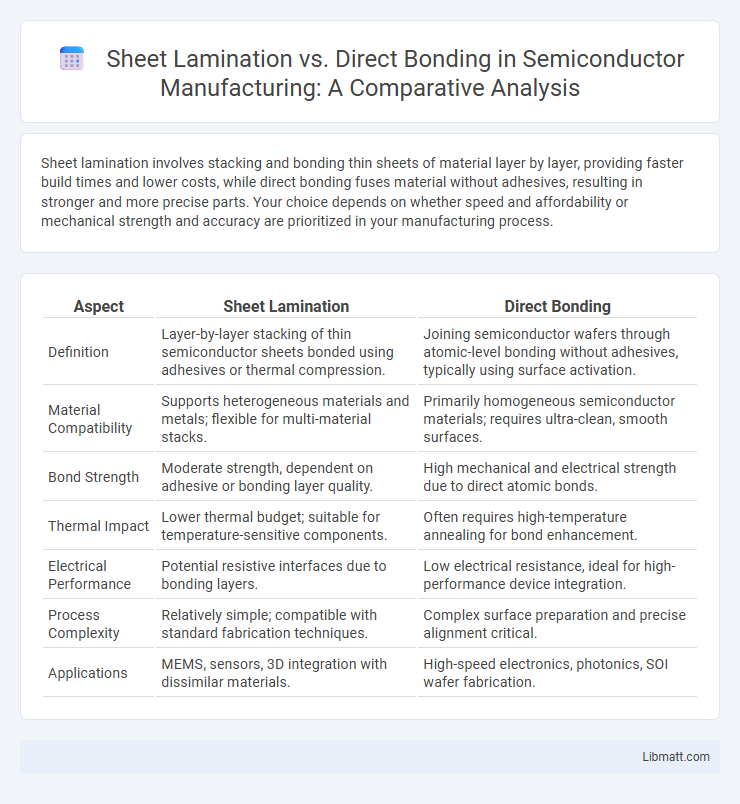

Sheet lamination involves stacking and bonding thin sheets of material layer by layer, providing faster build times and lower costs, while direct bonding fuses material without adhesives, resulting in stronger and more precise parts. Your choice depends on whether speed and affordability or mechanical strength and accuracy are prioritized in your manufacturing process.

Table of Comparison

| Aspect | Sheet Lamination | Direct Bonding |

|---|---|---|

| Definition | Layer-by-layer stacking of thin semiconductor sheets bonded using adhesives or thermal compression. | Joining semiconductor wafers through atomic-level bonding without adhesives, typically using surface activation. |

| Material Compatibility | Supports heterogeneous materials and metals; flexible for multi-material stacks. | Primarily homogeneous semiconductor materials; requires ultra-clean, smooth surfaces. |

| Bond Strength | Moderate strength, dependent on adhesive or bonding layer quality. | High mechanical and electrical strength due to direct atomic bonds. |

| Thermal Impact | Lower thermal budget; suitable for temperature-sensitive components. | Often requires high-temperature annealing for bond enhancement. |

| Electrical Performance | Potential resistive interfaces due to bonding layers. | Low electrical resistance, ideal for high-performance device integration. |

| Process Complexity | Relatively simple; compatible with standard fabrication techniques. | Complex surface preparation and precise alignment critical. |

| Applications | MEMS, sensors, 3D integration with dissimilar materials. | High-speed electronics, photonics, SOI wafer fabrication. |

Introduction to Sheet Lamination and Direct Bonding

Sheet Lamination involves stacking and bonding thin sheets of material layer by layer to create a solid 3D object, often used with metals, paper, or polymers for rapid prototyping and manufacturing. Direct Bonding, also known as diffusion bonding, fuses materials at the atomic level through high temperature and pressure without melting, ensuring strong, seamless joints ideal for advanced engineering applications. Your choice depends on factors like material compatibility, desired mechanical properties, and production speed.

Overview of Additive Manufacturing Techniques

Sheet lamination builds objects by stacking and bonding thin layers of material, typically paper, metal, or plastic sheets, using adhesives or ultrasonic welding. Direct bonding, also known as direct metal bonding, involves joining metal layers through heat and pressure without adhesives, resulting in highly dense and strong parts. Both techniques serve distinct roles in additive manufacturing, with sheet lamination favored for rapid prototyping and cost-effectiveness, while direct bonding excels in producing structurally robust metal components.

How Sheet Lamination Works

Sheet lamination builds 3D objects by stacking and bonding thin layers of material, usually paper, plastic, or metal sheets, which are cut according to the digital model. Each sheet is precisely aligned and fused through processes like adhesive application, ultrasonic welding, or thermal bonding to form a solid structure. This additive manufacturing method enables rapid prototyping and low-cost production with good mechanical properties and minimal post-processing.

The Direct Bonding Process Explained

Direct bonding is a process where two smooth, flat surfaces are joined at the atomic level without adhesives, relying on van der Waals forces and subsequent heat treatment to create a strong, permanent bond. This technique ensures high precision and durability, making it ideal for semiconductor and microelectromechanical systems (MEMS) manufacturing. Your projects benefit from enhanced material compatibility and reduced contamination risks compared to sheet lamination methods.

Materials Compatible with Sheet Lamination

Sheet lamination is compatible with a wide range of materials, including paper, plastic, metal foils, and composite laminates, enabling multi-material fabrication and rapid prototyping. Materials such as thermoplastics like ABS, PLA, and nylon, as well as metal sheets including aluminum and steel, are commonly utilized in sheet lamination processes like laminated object manufacturing (LOM). This versatility in material compatibility distinguishes sheet lamination from direct bonding, which often requires more homogeneous substrate materials for effective adhesion and mechanical performance.

Material Options for Direct Bonding

Direct bonding supports a range of material options including metals like aluminum, copper, and stainless steel, as well as ceramics and glass. These materials benefit from the atomic-level adhesion achieved without adhesives or interlayers, providing high mechanical strength and thermal stability. Unlike sheet lamination, which often limits choices to paper or polymer-based sheets, direct bonding enables the integration of high-performance materials suitable for aerospace, electronics, and biomedical applications.

Strengths and Limitations of Sheet Lamination

Sheet Lamination offers rapid prototyping and cost-effective production by stacking and bonding thin material layers, making it ideal for complex geometries and multi-material parts. Its limitations include lower resolution and surface finish quality compared to other additive manufacturing techniques, as well as challenges in achieving uniform bonding strength throughout the laminate. You should consider Sheet Lamination when prioritizing speed and material versatility over fine detail and surface smoothness in your projects.

Advantages and Drawbacks of Direct Bonding

Direct bonding offers superior mechanical strength and thermal conductivity compared to sheet lamination, making it ideal for high-performance applications. However, its process complexity and higher cost can limit scalability and increase production time. You should weigh these factors when choosing the best bonding method for your manufacturing needs.

Industrial Applications: Sheet Lamination vs Direct Bonding

Sheet lamination techniques, such as laminated object manufacturing (LOM), are widely used in rapid prototyping, architectural modeling, and tooling due to their ability to process various materials including paper, plastic, and metal sheets with relatively low cost and high speed. Direct bonding, commonly employed in semiconductor wafer bonding, microelectronics packaging, and advanced materials fabrication, offers superior bond strength and precision, enabling applications that require high thermal conductivity and hermetic sealing. Industrial sectors like automotive and aerospace leverage sheet lamination for manufacturing large, complex parts quickly, while microelectronics and MEMS industries prefer direct bonding for microscale device integration and reliability.

Choosing the Best Method: Key Considerations and Future Trends

Choosing the best method between sheet lamination and direct bonding depends on factors like material compatibility, desired mechanical properties, and production speed. Sheet lamination offers cost-effective manufacturing for complex geometries, while direct bonding provides superior structural integrity for high-performance applications. Future trends emphasize hybrid techniques combining both methods and the integration of AI-driven process optimization to enhance precision and reduce defects.

Sheet Lamination vs Direct Bonding Infographic

libmatt.com

libmatt.com