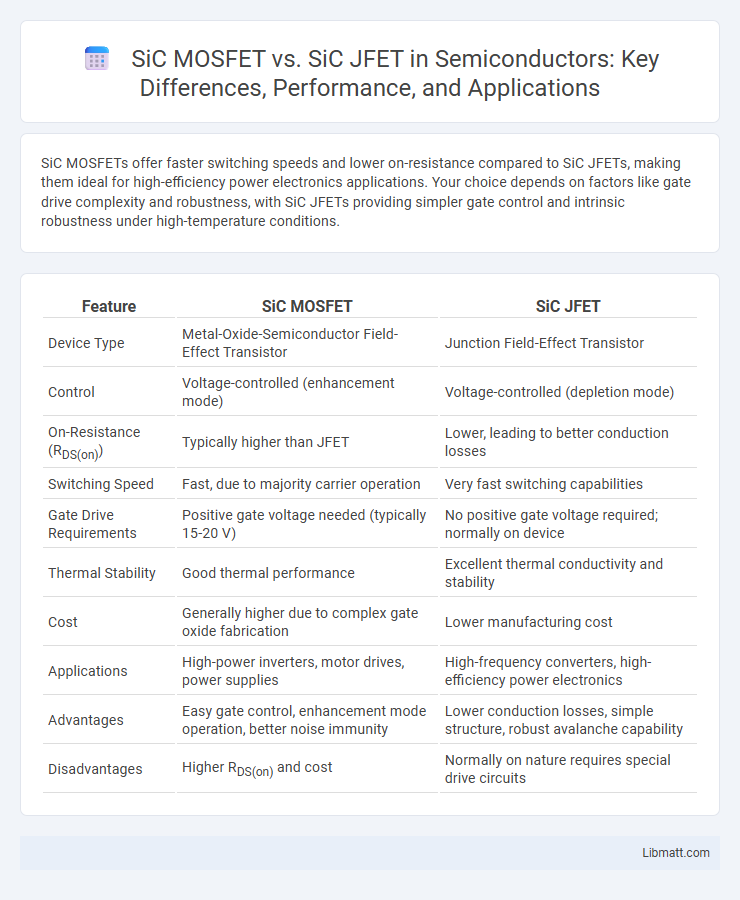

SiC MOSFETs offer faster switching speeds and lower on-resistance compared to SiC JFETs, making them ideal for high-efficiency power electronics applications. Your choice depends on factors like gate drive complexity and robustness, with SiC JFETs providing simpler gate control and intrinsic robustness under high-temperature conditions.

Table of Comparison

| Feature | SiC MOSFET | SiC JFET |

|---|---|---|

| Device Type | Metal-Oxide-Semiconductor Field-Effect Transistor | Junction Field-Effect Transistor |

| Control | Voltage-controlled (enhancement mode) | Voltage-controlled (depletion mode) |

| On-Resistance (RDS(on)) | Typically higher than JFET | Lower, leading to better conduction losses |

| Switching Speed | Fast, due to majority carrier operation | Very fast switching capabilities |

| Gate Drive Requirements | Positive gate voltage needed (typically 15-20 V) | No positive gate voltage required; normally on device |

| Thermal Stability | Good thermal performance | Excellent thermal conductivity and stability |

| Cost | Generally higher due to complex gate oxide fabrication | Lower manufacturing cost |

| Applications | High-power inverters, motor drives, power supplies | High-frequency converters, high-efficiency power electronics |

| Advantages | Easy gate control, enhancement mode operation, better noise immunity | Lower conduction losses, simple structure, robust avalanche capability |

| Disadvantages | Higher RDS(on) and cost | Normally on nature requires special drive circuits |

Introduction to SiC Power Devices

SiC MOSFETs and SiC JFETs are critical components in Silicon Carbide (SiC) power devices, offering superior efficiency and high-temperature performance compared to traditional silicon-based devices. SiC MOSFETs provide enhanced switching speed and reduced on-resistance, making them ideal for applications requiring precise control and high-frequency operation. In contrast, SiC JFETs deliver robust performance with a normally-on characteristic and lower conduction losses, suitable for high-voltage, high-current environments.

What is a SiC MOSFET?

A SiC MOSFET (Silicon Carbide Metal-Oxide-Semiconductor Field-Effect Transistor) is a high-performance power semiconductor device designed for efficient switching and low conduction losses in high-voltage applications. It features a gate oxide layer that controls the channel conductivity, enabling fast switching speeds, high thermal conductivity, and excellent voltage blocking capabilities. SiC MOSFETs are widely used in electric vehicles, renewable energy inverters, and industrial power supplies due to their superior efficiency and reliability compared to traditional silicon devices.

What is a SiC JFET?

A SiC JFET (Silicon Carbide Junction Field-Effect Transistor) is a type of semiconductor device designed for high-voltage and high-temperature applications, leveraging silicon carbide's wide bandgap properties. Unlike SiC MOSFETs, SiC JFETs offer normally-on operation and exhibit lower conduction losses with simpler gate structures, making them efficient for power switching. Their robustness and ability to operate at elevated temperatures make SiC JFETs ideal for automotive, industrial, and renewable energy systems requiring high efficiency and reliability.

Structural Differences: SiC MOSFET vs SiC JFET

SiC MOSFETs feature a metal-oxide-semiconductor gate structure allowing voltage-controlled operation with a thin oxide layer, enhancing switching speed and reducing gate leakage. SiC JFETs utilize a junction gate formed by pn junctions, providing normally-on behavior and simpler fabrication but requiring a negative gate voltage for turn-off. The oxide layer in SiC MOSFETs increases gate control precision, whereas SiC JFETs rely on depletion regions for current modulation.

Conductivity and On-Resistance Comparison

SiC MOSFETs typically exhibit lower on-resistance (R_DS(on)) due to their vertical channel design, which enhances conductivity and reduces power losses in high-voltage applications. SiC JFETs, while also offering excellent conductivity, generally have higher on-resistance because of their normally-on operation and channel structure, affecting efficiency during switching. The superior conductivity and lower on-resistance of SiC MOSFETs make them more suitable for energy-efficient power electronics requiring fast switching and minimal conduction losses.

Switching Speed and Efficiency

SiC MOSFETs provide faster switching speeds compared to SiC JFETs due to their majority carrier operation and lower gate charge, minimizing switching losses in high-frequency applications. Their improved efficiency results from reduced conduction resistance and enhanced control over threshold voltage, enabling better performance in power electronics. SiC JFETs, while robust, generally exhibit slower switching speed and higher conduction losses, making SiC MOSFETs the preferred choice for efficiency-critical, high-speed switching scenarios.

Gate Drive Requirements

SiC MOSFETs require a positive gate voltage (typically 15-20V) for full enhancement and have a voltage-controlled gate drive, enabling easier integration with standard gate drivers. SiC JFETs use a depletion-mode device requiring a negative gate voltage to turn off, making their gate drive circuits more complex and less compatible with traditional drivers. Your choice between SiC MOSFET and JFET will impact the complexity and cost of the gate drive design in power electronics applications.

Thermal Performance and Reliability

SiC MOSFETs exhibit superior thermal performance due to lower on-resistance and improved switching efficiency, enabling higher temperature operation and enhanced power density. SiC JFETs, known for robust reliability under harsh thermal conditions, maintain stable conduction with less thermal runaway risk due to their majority-carrier conduction mechanism. Both devices offer advantages, but SiC MOSFETs are preferred in applications demanding lower conduction losses and faster thermal cycling, while SiC JFETs excel in high-reliability, high-temperature environments.

Application Suitability: MOSFETs vs JFETs

SiC MOSFETs excel in high-frequency switching applications such as power converters and electric vehicles due to their low gate drive voltage and fast switching speeds, while SiC JFETs are preferred for rugged high-temperature environments and simple drive circuits because of their normally-on characteristic and robustness. MOSFETs offer better control and efficiency in PWM-controlled motor drives and renewable energy inverters, whereas JFETs provide superior reliability in harsh industrial or aerospace settings. Application suitability depends on the trade-off between control complexity and environmental robustness, with MOSFETs favored for precision power management and JFETs for durable, high-reliability systems.

Cost Analysis and Market Trends

SiC MOSFETs generally exhibit higher manufacturing costs compared to SiC JFETs due to complex fabrication techniques and enhanced performance features such as improved switching speeds and lower on-resistance. Market trends indicate growing adoption of SiC MOSFETs in EV and renewable energy sectors driven by their superior efficiency, while SiC JFETs remain preferred for cost-sensitive applications requiring robustness and simpler circuitry. Cost analysis reveals that despite higher initial investments, long-term energy savings and performance gains position SiC MOSFETs as a strategic choice in expanding high-power semiconductor markets.

SiC MOSFET vs SiC JFET Infographic

libmatt.com

libmatt.com