Dummy fill involves inserting placeholder text or values in a design or data structure to reserve space, while slot fill refers to dynamically populating these reserved areas with actual content or user-specific information. Understanding the distinction helps optimize workflows by ensuring your templates remain flexible and ready for real data integration.

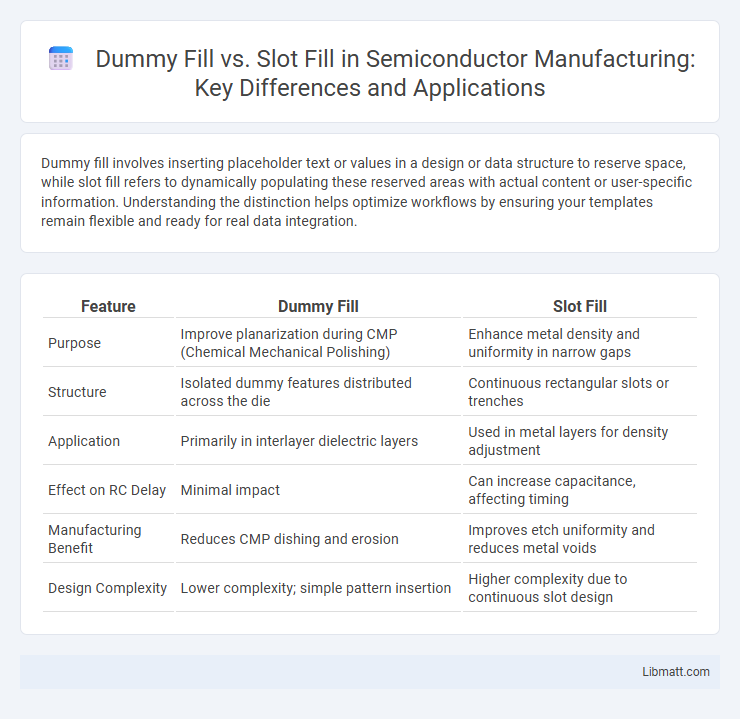

Table of Comparison

| Feature | Dummy Fill | Slot Fill |

|---|---|---|

| Purpose | Improve planarization during CMP (Chemical Mechanical Polishing) | Enhance metal density and uniformity in narrow gaps |

| Structure | Isolated dummy features distributed across the die | Continuous rectangular slots or trenches |

| Application | Primarily in interlayer dielectric layers | Used in metal layers for density adjustment |

| Effect on RC Delay | Minimal impact | Can increase capacitance, affecting timing |

| Manufacturing Benefit | Reduces CMP dishing and erosion | Improves etch uniformity and reduces metal voids |

| Design Complexity | Lower complexity; simple pattern insertion | Higher complexity due to continuous slot design |

Understanding Dummy Fill and Slot Fill

Dummy Fill refers to inserting placeholder content in website layouts to maintain design structure during the development phase, ensuring consistent visual flow without final text. Slot Fill involves dynamically injecting specific content or components into predefined areas or "slots" within a web application, allowing for flexible and context-driven user interfaces. Understanding the distinction helps optimize content management and user experience by balancing static placeholders with dynamic, context-aware content delivery.

Key Differences Between Dummy Fill and Slot Fill

Dummy Fill refers to placeholder content used temporarily in a template or layout, lacking meaningful or relevant data, while Slot Fill involves inserting actual, contextually appropriate information into predefined slots or fields. Dummy Fill is primarily utilized during the design phase or testing to visualize structure, whereas Slot Fill actively populates a system, form, or document with specific values to finalize output. Understanding the key differences allows you to effectively manage content development and ensure accurate data presentation in your projects.

Importance of Fill Techniques in Semiconductor Manufacturing

Dummy fill and slot fill techniques play a crucial role in semiconductor manufacturing by improving planarity and reducing chemical-mechanical polishing (CMP) dishing effects, which directly impact device performance and yield. Dummy fill involves adding non-functional structures to ensure uniform density, while slot fill strategically fills specific areas to prevent pattern distortion and enhance lithographic accuracy. Optimizing these fill methods ensures your chips maintain structural integrity and meet stringent quality standards essential for advanced integrated circuits.

Purpose and Functionality of Dummy Fill

Dummy fill serves primarily to improve the performance and manufacturability of semiconductor devices by filling unused areas on a wafer with non-functional features. These dummy structures help maintain uniform chemical-mechanical planarization (CMP) across the wafer, preventing issues like uneven polishing and layer thickness variation. In contrast, slot fill focuses on filling specific etched slots or trenches with functional materials to ensure electrical continuity and device integrity.

Slot Fill: Definition and Applications

Slot Fill refers to the process of identifying and extracting specific pieces of information, known as slots, from unstructured data to populate predefined templates or databases. Common applications include natural language understanding in virtual assistants, information retrieval in question-answering systems, and data extraction for customer service automation. Your ability to implement Slot Fill techniques enhances the accuracy and efficiency of systems relying on structured knowledge representation.

Impact on Yield and Device Performance

Dummy fill enhances chemical mechanical planarization (CMP) uniformity, improving yield by reducing dishing and erosion, but can introduce parasitic capacitance affecting device performance. Slot fill, tailored to specific layout patterns, minimizes metal density variation more precisely, offering better control over stress-induced defects and electrical characteristics. Choosing the appropriate fill technique directly influences yield optimization and device reliability in advanced semiconductor manufacturing.

Challenges Associated with Dummy and Slot Fills

Challenges associated with dummy fill include its potential to introduce inaccurate or irrelevant data, which can mislead semantic models and degrade natural language understanding accuracy. Slot fill, while more contextually precise, faces difficulties in handling ambiguous or missing information, often requiring complex algorithms to correctly interpret and extract relevant entities from varied inputs. Ensuring Your system distinguishes between meaningful slot fills and placeholders is crucial for maintaining data integrity and improving overall model reliability.

Design Considerations for Effective Fill Placement

Effective fill placement in Dummy Fill vs Slot Fill requires careful analysis of wafer topography to maintain planar uniformity and minimize pattern density variations. You must consider the impact of fill structures on CMP (chemical mechanical polishing) and etch uniformity, ensuring that fills do not interfere with signal integrity or device performance. Optimizing the size, shape, and distribution of fills helps achieve balanced stress and process uniformity across the entire chip layout.

Evolution of Filling Methods in Modern IC Design

Dummy fill and slot fill techniques have evolved to address the challenges of planarization and density uniformity in modern IC design, ensuring improved manufacturability and performance. Dummy fill involves adding non-functional geometric patterns to balance density, mitigating CMP (chemical-mechanical polishing) dishing and erosion, while slot fill strategically places fill patterns within empty slots to maintain topographical uniformity. Your choice between these methods impacts process control and device reliability, as each approach optimizes layout uniformity differently to meet evolving semiconductor fabrication requirements.

Future Trends in Fill Strategy Optimization

Future trends in fill strategy optimization emphasize integrating AI-driven predictive analytics to enhance accuracy in slot fill, reducing reliance on dummy fill placeholders that can lead to inefficiencies. Advanced natural language processing models will improve contextual understanding, enabling dynamic slot fill that adapts to user intent and data variability in real-time. Combining machine learning with semantic data enrichment offers scalable solutions for optimizing fill strategies across diverse industries, promoting higher precision and reduced operational costs.

Dummy Fill vs Slot Fill Infographic

libmatt.com

libmatt.com