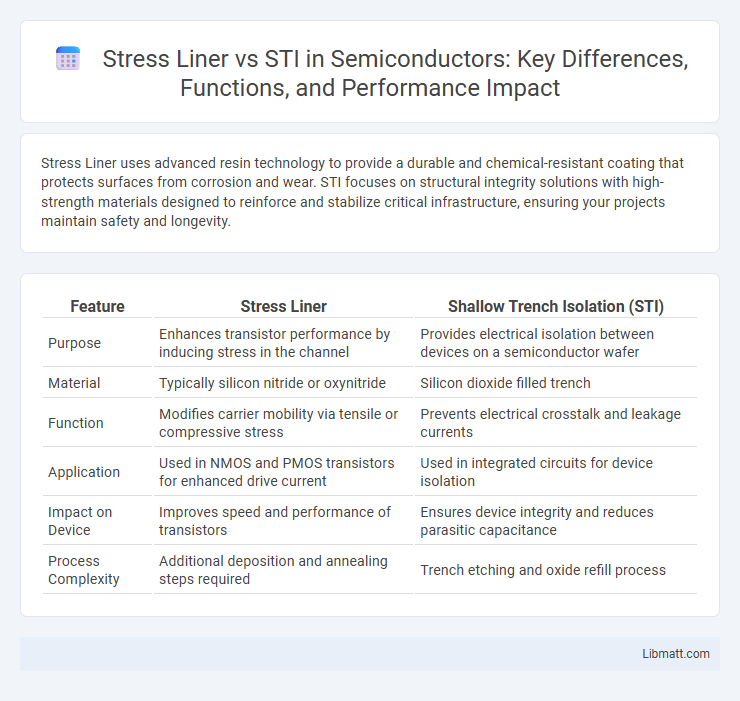

Stress Liner uses advanced resin technology to provide a durable and chemical-resistant coating that protects surfaces from corrosion and wear. STI focuses on structural integrity solutions with high-strength materials designed to reinforce and stabilize critical infrastructure, ensuring your projects maintain safety and longevity.

Table of Comparison

| Feature | Stress Liner | Shallow Trench Isolation (STI) |

|---|---|---|

| Purpose | Enhances transistor performance by inducing stress in the channel | Provides electrical isolation between devices on a semiconductor wafer |

| Material | Typically silicon nitride or oxynitride | Silicon dioxide filled trench |

| Function | Modifies carrier mobility via tensile or compressive stress | Prevents electrical crosstalk and leakage currents |

| Application | Used in NMOS and PMOS transistors for enhanced drive current | Used in integrated circuits for device isolation |

| Impact on Device | Improves speed and performance of transistors | Ensures device integrity and reduces parasitic capacitance |

| Process Complexity | Additional deposition and annealing steps required | Trench etching and oxide refill process |

Introduction to Stress Liners and STI

Stress liners are thin, flexible layers applied inside pipelines to isolate corrosion or repair damaged sections without extensive excavation. Stress Transfer Interfaces (STI) refer to engineered systems designed to redistribute mechanical stress within structures, enhancing durability and preventing failures. Both technologies improve infrastructure integrity by addressing stress-related issues through advanced material application and design techniques.

Understanding the Function of Stress Liners

Stress liners serve as crucial components in manufacturing processes by absorbing expansion and contraction forces to prevent damage in materials such as glass and ceramics. These liners distribute mechanical stress evenly, enhancing product durability and reducing breakage risks compared to standard STI applications. Their function is essential in industries requiring high precision and reliability, including electronics and automotive sectors.

What is STI (Shallow Trench Isolation)?

STI (Shallow Trench Isolation) is a semiconductor fabrication technique used to isolate neighboring transistors in integrated circuits by etching shallow trenches in the silicon substrate and filling them with an insulating material like silicon dioxide. This method improves device performance by minimizing electrical leakage and crosstalk between components, enabling higher packing densities on chips compared to traditional Stress Liner isolation. STI is critical in advanced CMOS technology nodes for achieving precise transistor separation and enhanced reliability in microelectronics.

Key Differences Between Stress Liner and STI

Stress Liner is a specialized product designed to control shrinkage and provide a smooth finish in concrete surfaces, while STI (Strain Tolerant Interface) focuses on accommodating movement and preventing cracking in expansion joints. Stress Liner enhances durability by minimizing surface tension, whereas STI improves structural integrity through flexibility and strain absorption. Understanding these key differences helps you select the optimal solution for specific construction needs and performance requirements.

Material Composition: Stress Liner vs STI

Stress Liner pipes are engineered with a robust composite structure, typically featuring a high-strength polymer core fused with a corrosion-resistant outer layer, designed to withstand extreme pressures and aggressive chemical environments. In contrast, STI pipes primarily utilize carbon steel with advanced alloy treatments, offering superior tensile strength and thermal resistance for industrial applications. The material composition of Stress Liner emphasizes lightweight durability and corrosion resistance, while STI focuses on mechanical strength and high-temperature tolerance.

Impact on Semiconductor Performance

Stress liners enhance semiconductor performance by introducing controlled mechanical strain into transistor channels, which boosts carrier mobility and increases switching speed, leading to improved device efficiency. STI (Shallow Trench Isolation) defines active regions by electrically isolating transistors, minimizing leakage currents and crosstalk, thereby stabilizing device operation. Your choice between stress liner and STI directly affects transistor speed, power consumption, and overall chip reliability in integrated circuits.

Manufacturing Process Comparison

The manufacturing process of Stress Liner involves applied stress to create a permanent deformation that enhances durability and dimensional stability, typically through controlled tensile forces during production. In contrast, STI (Stress Transfer Interface) manufacturing emphasizes the integration of materials with different mechanical properties to optimize stress distribution, often utilizing layered composites or bonded interfaces. Stress Liner production focuses on uniform stress application for improved resilience, whereas STI manufacturing prioritizes material synergy and interface engineering for functional performance.

Reliability and Longevity: Stress Liner vs STI

Stress Liner systems offer high reliability due to their corrosion-resistant materials and robust design, ensuring consistent performance in harsh environments. STI (Strain Transfer Instrumentation) devices provide precise stress measurements but may require regular calibration and maintenance to maintain accuracy over time. Long-term durability favors Stress Liners in underground applications where structural integrity is critical, while STI excels in monitoring dynamic stress changes with reliable data acquisition.

Applications in Modern IC Design

Stress liners enhance transistor performance by applying mechanical strain to the channel, boosting carrier mobility and drive current in advanced logic circuits. STI (Shallow Trench Isolation) provides electrical isolation between devices, preventing leakage and crosstalk in densely packed IC layouts. Combining stress liners with STI optimizes both device isolation and transistor speed, crucial for high-performance CPUs and SoCs in modern IC design.

Future Trends in Stress Liners and STI Technology

Future trends in Stress Liners and STI (Shallow Trench Isolation) technology emphasize enhanced precision and scalability to support advanced semiconductor nodes below 5nm. Innovations include integrating novel materials like high-k dielectrics and stress-engineered liners to improve device performance and reduce parasitic capacitance. Machine learning algorithms are increasingly utilized to optimize fabrication processes, enabling more efficient STI formation and improved stress liner uniformity for next-generation integrated circuits.

Stress Liner vs STI Infographic

libmatt.com

libmatt.com