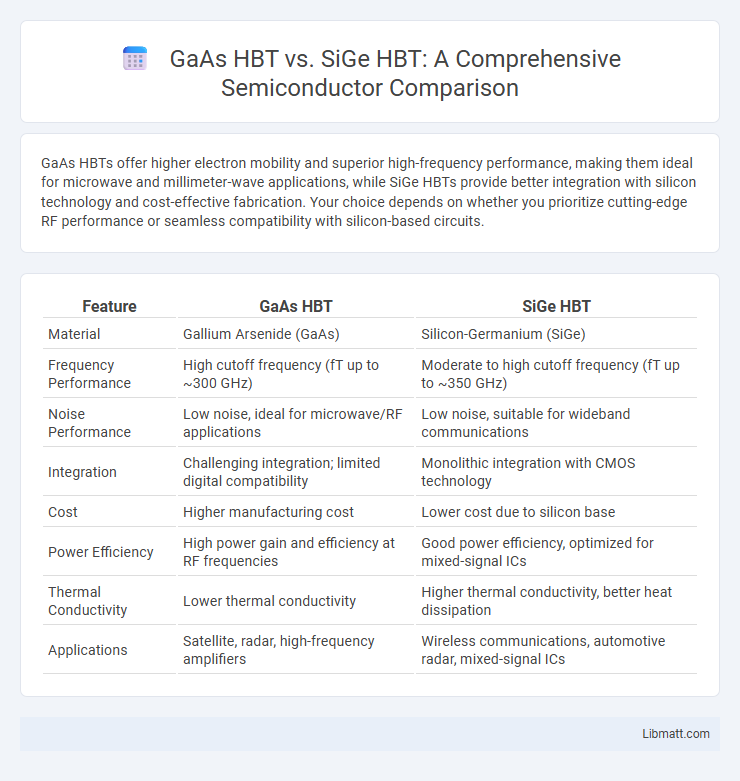

GaAs HBTs offer higher electron mobility and superior high-frequency performance, making them ideal for microwave and millimeter-wave applications, while SiGe HBTs provide better integration with silicon technology and cost-effective fabrication. Your choice depends on whether you prioritize cutting-edge RF performance or seamless compatibility with silicon-based circuits.

Table of Comparison

| Feature | GaAs HBT | SiGe HBT |

|---|---|---|

| Material | Gallium Arsenide (GaAs) | Silicon-Germanium (SiGe) |

| Frequency Performance | High cutoff frequency (fT up to ~300 GHz) | Moderate to high cutoff frequency (fT up to ~350 GHz) |

| Noise Performance | Low noise, ideal for microwave/RF applications | Low noise, suitable for wideband communications |

| Integration | Challenging integration; limited digital compatibility | Monolithic integration with CMOS technology |

| Cost | Higher manufacturing cost | Lower cost due to silicon base |

| Power Efficiency | High power gain and efficiency at RF frequencies | Good power efficiency, optimized for mixed-signal ICs |

| Thermal Conductivity | Lower thermal conductivity | Higher thermal conductivity, better heat dissipation |

| Applications | Satellite, radar, high-frequency amplifiers | Wireless communications, automotive radar, mixed-signal ICs |

Introduction to GaAs HBT and SiGe HBT

GaAs Heterojunction Bipolar Transistors (HBTs) utilize gallium arsenide semiconductor material to achieve high electron mobility and superior frequency response, making them ideal for high-speed RF and microwave applications. SiGe HBTs incorporate silicon-germanium alloys in the base region, enhancing carrier injection efficiency and enabling integration with mainstream silicon CMOS technology for cost-effective, high-performance solutions. Both GaAs HBT and SiGe HBT are essential in communication systems, with GaAs devices excelling in power and frequency, while SiGe HBTs offer a balance of speed, integration, and manufacturing scalability.

Fundamental Working Principles

Gallium Arsenide (GaAs) Heterojunction Bipolar Transistors (HBTs) utilize a heterojunction formed between GaAs and AlGaAs materials, enabling higher electron mobility and faster switching speeds due to reduced base resistance and improved electron injection efficiency. Silicon-Germanium (SiGe) HBTs integrate a graded SiGe base layer with silicon emitter and collector regions, enhancing carrier transport by bandgap engineering and strain effects to achieve a high current gain and frequency response. Both devices leverage heterojunctions to optimize charge carrier flow, but GaAs HBTs excel in high-frequency applications, while SiGe HBTs balance performance with CMOS compatibility and cost efficiency.

Material Properties Comparison

GaAs HBTs leverage the direct bandgap and high electron mobility of gallium arsenide, enabling faster switching speeds and higher frequency performance compared to SiGe HBTs, which utilize silicon-germanium alloy's compatibility with silicon processes and better thermal conductivity. GaAs offers superior electron saturation velocity and lower noise figures, enhancing analog and RF applications, while SiGe balances performance with cost-effective integration in silicon-based circuits. Your choice between GaAs and SiGe HBTs depends on whether ultra-high frequency operation or seamless silicon integration is prioritized.

Electrical Performance Metrics

GaAs HBTs deliver higher electron mobility and superior frequency response, making them ideal for high-speed RF applications with enhanced cutoff frequencies (fT) often exceeding 100 GHz. SiGe HBTs provide better integration with silicon technology, offering lower noise figures and improved linearity crucial for broadband communication systems. Your choice depends on the required balance between power efficiency, gain, and fabrication cost for specific electrical performance metrics.

Frequency Response and Bandwidth

GaAs HBTs (Gallium Arsenide Heterojunction Bipolar Transistors) typically exhibit superior frequency response and wider bandwidth compared to SiGe HBTs (Silicon-Germanium Heterojunction Bipolar Transistors) due to higher electron mobility and lower parasitic capacitances. GaAs HBTs can achieve cut-off frequencies (fT) exceeding 300 GHz, making them ideal for millimeter-wave applications, while SiGe HBTs generally reach up to approximately 300 GHz but with improved integration and cost advantages. The higher saturation velocity in GaAs affords better high-frequency performance, whereas SiGe offers bandwidth optimization through advanced CMOS-compatible manufacturing processes.

Power Efficiency and Thermal Management

GaAs HBTs offer superior power efficiency due to their higher electron mobility and wider bandgap, enabling faster switching speeds and lower power consumption compared to SiGe HBTs. However, SiGe HBTs provide better thermal management because silicon substrates have higher thermal conductivity, allowing more effective heat dissipation during operation. Your choice between GaAs and SiGe HBTs should balance power efficiency needs against thermal constraints specific to your application.

Integration with Existing Technologies

GaAs HBTs offer superior electron mobility and high-frequency performance but face integration challenges with silicon-based CMOS due to lattice mismatch and higher costs. SiGe HBTs leverage compatibility with standard silicon fabrication processes, enabling seamless integration into existing CMOS technologies and reducing manufacturing expenses. This compatibility makes SiGe HBTs ideal for mixed-signal and RF applications within well-established silicon platforms.

Fabrication Processes and Cost Analysis

GaAs HBTs (Gallium Arsenide Heterojunction Bipolar Transistors) utilize compound semiconductor fabrication involving complex epitaxial growth and wafer handling, resulting in higher manufacturing costs compared to SiGe HBTs (Silicon Germanium Heterojunction Bipolar Transistors), which leverage silicon-based processes compatible with standard CMOS technology. The cost efficiency of SiGe HBT fabrication stems from mature silicon foundry infrastructure and economies of scale, making it more suitable for high-volume applications. Your choice between the two depends on balancing GaAs HBT's superior high-frequency performance against the cost-effective, scalable SiGe HBT production.

Typical Applications and Use Cases

GaAs HBTs excel in high-frequency and high-power applications such as RF amplifiers, satellite communications, and radar systems due to their superior electron mobility and power efficiency. SiGe HBTs are widely used in mixed-signal integrated circuits, high-speed digital communication, and low-noise amplifiers, benefiting from their compatibility with standard silicon CMOS processes and integration capabilities. Your choice between GaAs and SiGe HBT technologies depends on performance requirements, cost constraints, and application-specific needs in wireless infrastructure or semiconductor devices.

Future Trends and Advancements

GaAs HBTs continue to demonstrate superior high-frequency performance and power efficiency, making them ideal for emerging 5G and millimeter-wave applications, while SiGe HBTs leverage CMOS compatibility and cost-effectiveness for large-scale integration in next-generation RF front-ends. Future trends indicate GaAs HBT advancements in epitaxial growth and device scaling, improving linearity and thermal stability, whereas SiGe HBTs benefit from enhanced heterojunction engineering and strain techniques to push speed and noise figures closer to GaAs levels. Your choice between GaAs and SiGe HBT technologies will depend on balancing performance requirements with integration and manufacturing considerations in rapidly evolving wireless communication systems.

GaAs HBT vs SiGe HBT Infographic

libmatt.com

libmatt.com