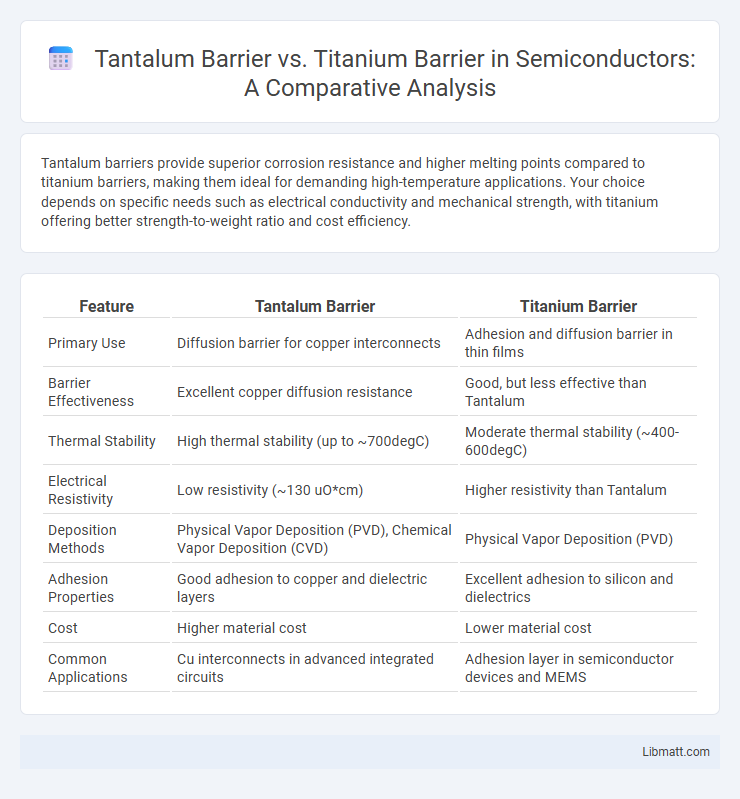

Tantalum barriers provide superior corrosion resistance and higher melting points compared to titanium barriers, making them ideal for demanding high-temperature applications. Your choice depends on specific needs such as electrical conductivity and mechanical strength, with titanium offering better strength-to-weight ratio and cost efficiency.

Table of Comparison

| Feature | Tantalum Barrier | Titanium Barrier |

|---|---|---|

| Primary Use | Diffusion barrier for copper interconnects | Adhesion and diffusion barrier in thin films |

| Barrier Effectiveness | Excellent copper diffusion resistance | Good, but less effective than Tantalum |

| Thermal Stability | High thermal stability (up to ~700degC) | Moderate thermal stability (~400-600degC) |

| Electrical Resistivity | Low resistivity (~130 uO*cm) | Higher resistivity than Tantalum |

| Deposition Methods | Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD) | Physical Vapor Deposition (PVD) |

| Adhesion Properties | Good adhesion to copper and dielectric layers | Excellent adhesion to silicon and dielectrics |

| Cost | Higher material cost | Lower material cost |

| Common Applications | Cu interconnects in advanced integrated circuits | Adhesion layer in semiconductor devices and MEMS |

Introduction to Tantalum and Titanium Barriers

Tantalum and titanium barriers are critical components in microelectronics and semiconductor manufacturing, offering distinct properties that influence device performance. Tantalum barriers provide excellent corrosion resistance and high melting point, making them suitable for high-temperature applications, while titanium barriers excel in adhesion and act as effective diffusion barriers. Their specific roles in preventing metal interdiffusion and enhancing structural integrity are essential for reliable and efficient electronic devices.

Material Properties Comparison

Tantalum barriers exhibit superior corrosion resistance and higher melting points compared to titanium barriers, making them ideal for high-temperature and aggressive chemical environments. Titanium barriers offer excellent strength-to-weight ratios and are more cost-effective, with strong biocompatibility for medical applications. Your choice depends on the specific material property requirements such as thermal stability, chemical resistance, and budget constraints.

Corrosion Resistance: Tantalum vs Titanium

Tantalum exhibits superior corrosion resistance compared to titanium due to its stable oxide layer that protects against aggressive environments, including acids and saline solutions. Titanium also resists corrosion effectively, especially in oxidizing environments, but its performance declines in reducing or highly acidic conditions where tantalum excels. When selecting a barrier for your application, consider tantalum for extreme corrosion resistance and titanium for general durability with lighter weight benefits.

Thermal and Electrical Conductivity Differences

Tantalum barrier exhibits lower thermal conductivity compared to titanium, making it more effective in high-temperature applications where heat retention is critical. Titanium offers superior electrical conductivity, which enhances performance in electronic components requiring efficient current flow. Your choice between tantalum and titanium barriers should consider the specific thermal and electrical conductivity demands of your application.

Barrier Performance in Semiconductor Applications

Tantalum barriers exhibit superior resistance to copper diffusion and excellent thermal stability, making them highly effective in preventing metal interdiffusion in semiconductor interconnects. Titanium barriers provide good adhesion and moderate diffusion resistance but generally show higher susceptibility to electromigration compared to tantalum. In advanced semiconductor applications, tantalum barriers are preferred for their enhanced reliability and longer lifespan under high current densities and elevated temperatures.

Mechanical Strength and Durability

Tantalum barriers exhibit superior mechanical strength due to their high tensile strength and excellent resistance to deformation under stress, making them ideal for applications requiring long-term durability. Titanium barriers also offer notable strength but can be more prone to fatigue and wear in harsh environments compared to tantalum. The corrosion resistance of tantalum further enhances its durability, outperforming titanium in aggressive chemical and thermal conditions.

Fabrication and Deposition Techniques

Tantalum barriers are commonly fabricated using physical vapor deposition (PVD) and chemical vapor deposition (CVD) methods, offering excellent conformality and strong adhesion to silicon substrates. Titanium barriers are typically deposited using sputtering techniques and atomic layer deposition (ALD), providing good step coverage and low impurity incorporation in semiconductor applications. The choice between tantalum and titanium barriers depends on the required electrical properties, thermal stability, and compatibility with subsequent metallization processes.

Cost Analysis and Economic Considerations

Tantalum barriers typically incur higher material and production costs compared to titanium barriers due to the rarity and complex processing of tantalum. While titanium offers cost-efficiency and widespread availability, its lower density and corrosion resistance might affect long-term durability and maintenance expenses. Evaluating Your project budget should balance initial costs against lifecycle performance to determine the most economically viable barrier material.

Industry Use Cases and Adoption Trends

Tantalum barriers are widely used in the semiconductor and aerospace industries due to their excellent corrosion resistance and high melting point, making them ideal for high-temperature and harsh environment applications. Titanium barriers, favored in medical devices and automotive sectors, provide superior strength-to-weight ratio and biocompatibility, driving adoption for implants and lightweight structural components. Your choice between tantalum and titanium barriers depends on specific industry requirements, balancing factors such as durability, cost, and environmental conditions.

Future Prospects in Barrier Material Technology

Tantalum barriers offer superior corrosion resistance and electrical conductivity, making them a strong candidate for next-generation semiconductor devices, while titanium barriers are favored for their mechanical strength and lower cost. Emerging research focuses on enhancing the integration of tantalum with advanced nanostructures to improve durability and performance at smaller scales, addressing the demands of future high-performance electronics. Your choice between tantalum and titanium barriers will depend on specific device requirements, but tantalum's promising future in barrier material technology is reshaping industry standards.

Tantalum Barrier vs Titanium Barrier Infographic

libmatt.com

libmatt.com