Gold wire bond offers superior corrosion resistance and excellent conductivity, making it ideal for high-reliability applications, while copper wire bond provides higher electrical and thermal conductivity at a lower cost but may require protective coatings to prevent oxidation. Your choice depends on balancing cost, performance, and environmental durability to suit the specific requirements of your electronic device.

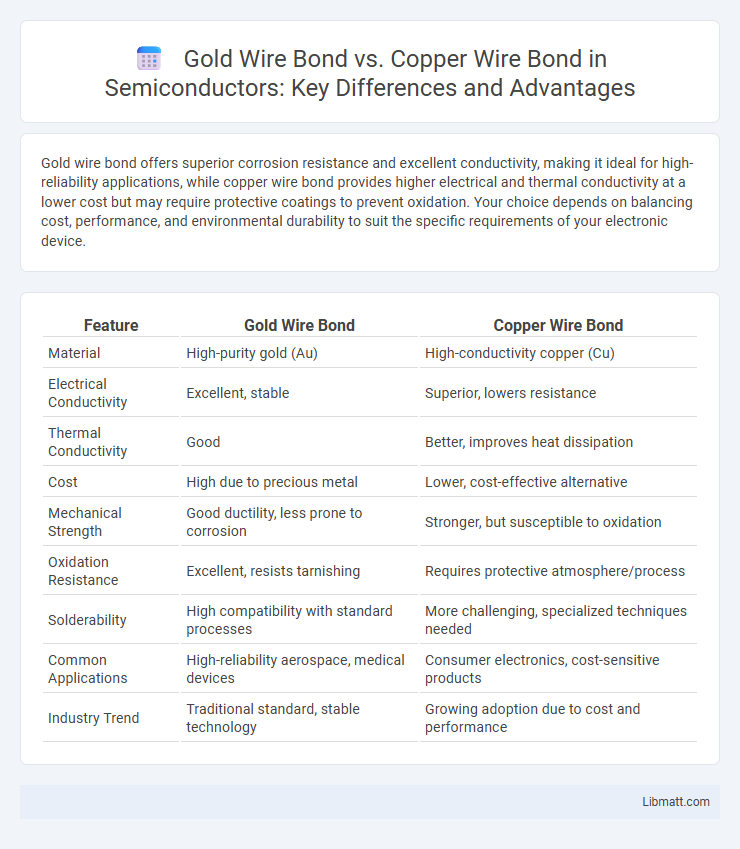

Table of Comparison

| Feature | Gold Wire Bond | Copper Wire Bond |

|---|---|---|

| Material | High-purity gold (Au) | High-conductivity copper (Cu) |

| Electrical Conductivity | Excellent, stable | Superior, lowers resistance |

| Thermal Conductivity | Good | Better, improves heat dissipation |

| Cost | High due to precious metal | Lower, cost-effective alternative |

| Mechanical Strength | Good ductility, less prone to corrosion | Stronger, but susceptible to oxidation |

| Oxidation Resistance | Excellent, resists tarnishing | Requires protective atmosphere/process |

| Solderability | High compatibility with standard processes | More challenging, specialized techniques needed |

| Common Applications | High-reliability aerospace, medical devices | Consumer electronics, cost-sensitive products |

| Industry Trend | Traditional standard, stable technology | Growing adoption due to cost and performance |

Introduction to Wire Bonding: Gold vs Copper

Wire bonding is a critical process in semiconductor packaging where fine wires connect a chip to its external circuitry. Gold wire bonding offers excellent corrosion resistance, high conductivity, and reliable performance in harsh environments, making it a preferred choice for high-reliability applications. Copper wire bonding is gaining popularity due to its lower cost and higher electrical and thermal conductivity, although it requires advanced techniques to manage oxidation and mechanical strength challenges.

Material Properties: Gold Wire vs Copper Wire

Gold wire bond exhibits excellent corrosion resistance, superior ductility, and consistent electrical conductivity, making it ideal for highly reliable semiconductor connections. Copper wire bond provides higher electrical and thermal conductivity with lower material costs but requires protective measures against oxidation to maintain performance. Your choice depends on balancing material properties with cost and application-specific requirements in electronic packaging.

Electrical Conductivity and Performance

Copper wire bonds exhibit superior electrical conductivity, approximately 40% higher than gold wire bonds, resulting in lower electrical resistance and enhanced performance in high-frequency applications. Gold wire bonds, while offering excellent corrosion resistance and ease of bonding, may experience increased signal loss compared to copper wire bonds due to their higher resistivity. The choice between gold and copper wire bonds significantly impacts the efficiency and reliability of semiconductor devices, with copper favored for advanced, high-performance circuits requiring optimal electrical properties.

Cost Comparison: Gold and Copper Wire Bonds

Gold wire bonds typically cost significantly more than copper wire bonds due to the high market price of gold, averaging around $60 per gram compared to copper's $0.01 per gram. Despite the higher initial expense, gold offers superior corrosion resistance and reliable electrical conductivity, which may reduce long-term costs in specific applications. Copper wire bonds, while cheaper, require protective coatings to prevent oxidation, potentially increasing processing expenses and impacting overall cost-effectiveness.

Reliability and Durability in Different Environments

Gold wire bonds offer superior corrosion resistance and stable electrical performance in harsh environments, making them highly reliable for long-term durability. Copper wire bonds provide excellent mechanical strength and thermal conductivity but may require protective coatings to prevent oxidation in humid or corrosive conditions. Your choice depends on the specific environmental challenges and reliability requirements of your application.

Bonding Process Differences

Gold wire bond utilizes thermosonic bonding, combining ultrasonic energy, heat, and pressure to form reliable intermetallic compounds on gold pads, whereas copper wire bond commonly requires higher bonding forces and inert atmosphere to prevent oxidation during thermosonic or ultrasonic bonding. Copper wire bonding demands more precise control of bonding parameters to avoid pad damage due to its hardness and oxidation tendency, contrasting with gold's inherent oxidation resistance and ductility. The bonding process for copper also involves pre- or post-bond cleaning steps to ensure bond integrity, while gold bonding generally has fewer stringent surface preparation requirements.

Challenges in Gold and Copper Wire Bonding

Gold wire bonding faces challenges such as high material cost and susceptibility to stitch and ball defects under high-temperature conditions. Copper wire bonding encounters issues like increased hardness causing equipment wear, risk of oxidation affecting bond reliability, and the need for specialized bonding parameters to prevent intermetallic formation. Both materials require precise process control to optimize bond strength and minimize defects in semiconductor packaging.

Applications in Semiconductor Packaging

Gold wire bonding remains prevalent in semiconductor packaging for its excellent conductivity, corrosion resistance, and reliability in high-frequency applications like RF devices and sensors. Copper wire bonding offers cost-efficiency and superior electrical performance, making it ideal for power semiconductors and devices requiring robust thermal management. Understanding your application's specific thermal and electrical demands will help determine whether gold or copper wire bonds best enhance device performance and longevity.

Industry Trends and Adoption Rates

Copper wire bond adoption has surged in the semiconductor industry due to its lower cost and superior electrical conductivity compared to gold wire bond. Industry trends reveal a growing preference for copper in high-volume applications, driven by advancements in corrosion resistance and bonding techniques. Your choice of wire bond material can impact production efficiency and overall device performance in rapidly evolving electronics markets.

Future Prospects in Wire Bond Technology

Copper wire bonds are increasingly favored in the semiconductor industry due to their lower cost, higher electrical conductivity, and improved mechanical strength compared to traditional gold wire bonds. Advancements in copper wire bonding techniques, such as improved oxidation resistance and finer wire diameters, enhance reliability and enable higher-density microelectronic packaging. Your choice between gold and copper wire bonds will be influenced by these future trends emphasizing performance, cost efficiency, and integration capabilities in next-generation electronic devices.

Gold Wire Bond vs Copper Wire Bond Infographic

libmatt.com

libmatt.com