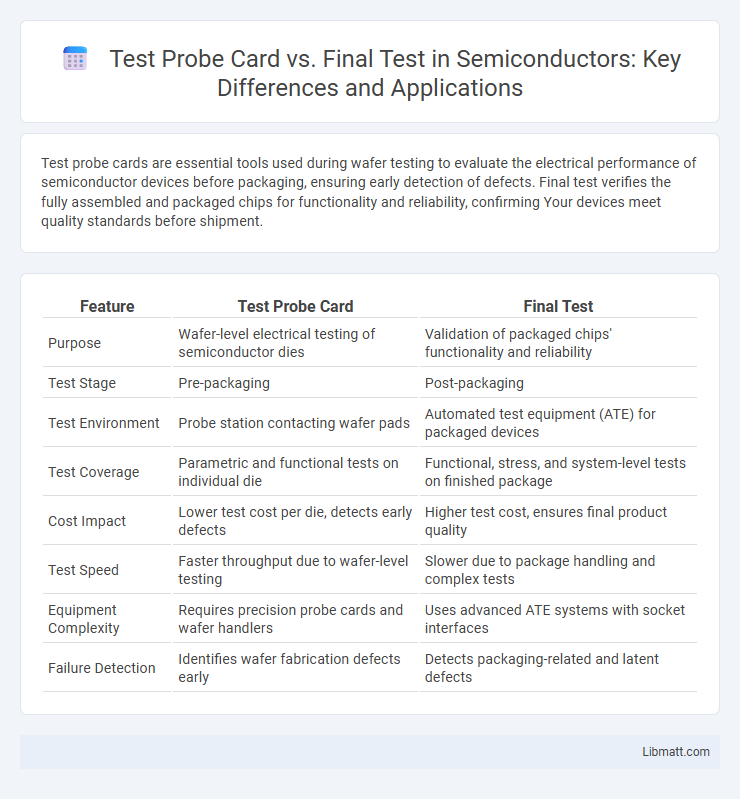

Test probe cards are essential tools used during wafer testing to evaluate the electrical performance of semiconductor devices before packaging, ensuring early detection of defects. Final test verifies the fully assembled and packaged chips for functionality and reliability, confirming Your devices meet quality standards before shipment.

Table of Comparison

| Feature | Test Probe Card | Final Test |

|---|---|---|

| Purpose | Wafer-level electrical testing of semiconductor dies | Validation of packaged chips' functionality and reliability |

| Test Stage | Pre-packaging | Post-packaging |

| Test Environment | Probe station contacting wafer pads | Automated test equipment (ATE) for packaged devices |

| Test Coverage | Parametric and functional tests on individual die | Functional, stress, and system-level tests on finished package |

| Cost Impact | Lower test cost per die, detects early defects | Higher test cost, ensures final product quality |

| Test Speed | Faster throughput due to wafer-level testing | Slower due to package handling and complex tests |

| Equipment Complexity | Requires precision probe cards and wafer handlers | Uses advanced ATE systems with socket interfaces |

| Failure Detection | Identifies wafer fabrication defects early | Detects packaging-related and latent defects |

Introduction to Test Probe Card and Final Test

Test probe cards are critical tools used during wafer testing to establish electrical connections between the test equipment and semiconductor devices, enabling early detection of defects on integrated circuits. Final test is the last phase in semiconductor manufacturing where fully packaged chips undergo comprehensive performance verification to ensure functionality and reliability before shipment. The distinction lies in test probe cards targeting wafer-level assessment, while final tests confirm the quality of finished products.

Overview of Semiconductor Testing Stages

Test Probe Card plays a critical role in semiconductor testing by establishing an interface between the test equipment and the wafer, enabling initial electrical assessments of integrated circuits during wafer probing. Final Test occurs after wafer dicing and packaging, where fully assembled semiconductor devices undergo comprehensive functional and parametric testing to ensure performance and reliability. These distinct stages collectively ensure defect identification and quality control throughout semiconductor manufacturing.

What is a Test Probe Card?

A Test Probe Card is a specialized interface device used in semiconductor manufacturing to connect test equipment to the integrated circuits on a wafer during the wafer sort process. It enables electrical testing of chip functionality and performance before the die are separated, ensuring early defect detection. Your choice of probe card directly impacts test accuracy and efficiency in the final test phase.

Defining Final Test in Semiconductor Manufacturing

Final Test in semiconductor manufacturing refers to the critical phase where fully assembled and packaged chips undergo comprehensive electrical testing to ensure functionality, performance, and reliability before shipment. Unlike test probe cards that interface directly with wafer-level devices to detect defects early, Final Test evaluates finished products under actual operating conditions to verify compliance with design specifications and quality standards. This stage is essential for identifying latent failures and categorizing parts for yield analysis and binning.

Key Differences Between Probe Card and Final Test

Test probe cards are specialized tools used during wafer-level testing to physically contact semiconductor chips and measure electrical parameters, ensuring device functionality before packaging. Final test refers to the comprehensive evaluation phase after packaging, where the fully assembled semiconductor device undergoes performance validation under real-world operating conditions. Understanding the key differences between probe card testing and final test helps optimize your semiconductor production by distinguishing between wafer-level screening and final device verification.

Advantages of Probe Card Testing

Probe card testing offers precise wafer-level electrical characterization, enabling early detection of defects before packaging and assembly. This method reduces manufacturing costs by minimizing wasted materials and shortening the production cycle. High-throughput testing with probe cards ensures improved yield and reliable quality control for semiconductor devices.

Benefits of Final Test for Quality Assurance

Final Test ensures comprehensive quality assurance by verifying the complete functionality of semiconductor devices under actual operating conditions, leading to higher reliability and performance consistency. This process identifies latent defects missed during Test Probe Card testing, reducing the risk of field failures and warranty costs. Implementing Final Test enhances customer satisfaction through improved yield accuracy and defect detection rates.

Challenges in Probe Card and Final Test Processes

Test probe cards face challenges such as ensuring precise alignment with semiconductor wafers to maintain signal integrity and avoid damage, while coping with high contact resistance and wear during multiple test cycles. Final test processes demand accurate functional verification under various environmental conditions, requiring sophisticated test algorithms to identify subtle device failures and maintain throughput efficiency. Optimizing Your probe card and final test strategies involves balancing test accuracy, equipment durability, and cost-effectiveness to achieve reliable semiconductor quality assurance.

Choosing Between Probe Card and Final Test

Choosing between a test probe card and a final test hinges on balancing cost, accuracy, and test coverage in semiconductor manufacturing. Probe cards offer rapid, wafer-level testing to identify defects early, enabling cost-effective screening before packaging. Final tests deliver comprehensive chip verification, ensuring functionality under real-world conditions but at higher expense and time investment.

Future Trends in Semiconductor Testing Technologies

Test Probe Cards are evolving with advancements in precision and multi-site testing capabilities, enabling faster and more accurate wafer-level diagnostics. Final Test processes are integrating AI-driven analytics and high-throughput systems to enhance defect detection and yield optimization at the packaged chip stage. Future trends emphasize the convergence of real-time data analytics, adaptive testing algorithms, and scalable automation to meet the increasing complexity and miniaturization of semiconductor devices.

Test Probe Card vs Final Test Infographic

libmatt.com

libmatt.com