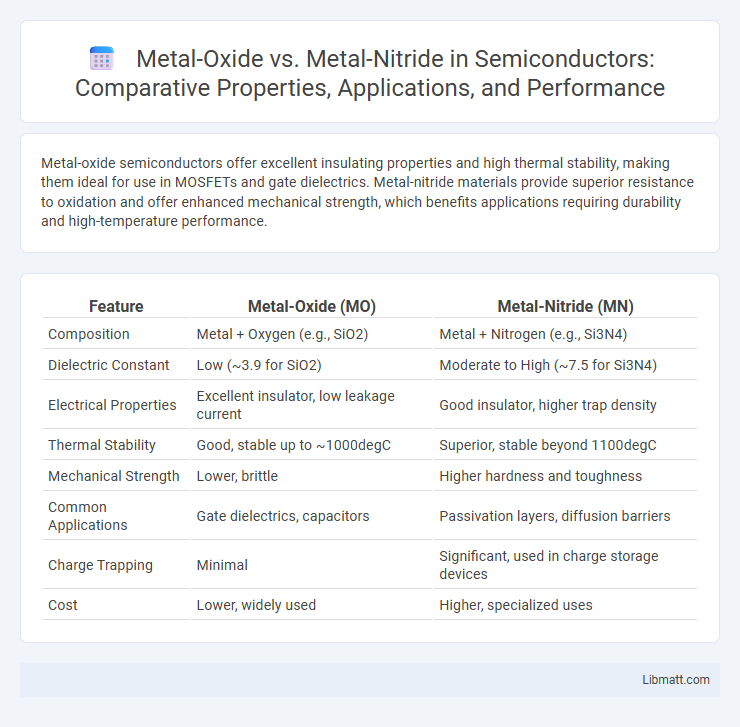

Metal-oxide semiconductors offer excellent insulating properties and high thermal stability, making them ideal for use in MOSFETs and gate dielectrics. Metal-nitride materials provide superior resistance to oxidation and offer enhanced mechanical strength, which benefits applications requiring durability and high-temperature performance.

Table of Comparison

| Feature | Metal-Oxide (MO) | Metal-Nitride (MN) |

|---|---|---|

| Composition | Metal + Oxygen (e.g., SiO2) | Metal + Nitrogen (e.g., Si3N4) |

| Dielectric Constant | Low (~3.9 for SiO2) | Moderate to High (~7.5 for Si3N4) |

| Electrical Properties | Excellent insulator, low leakage current | Good insulator, higher trap density |

| Thermal Stability | Good, stable up to ~1000degC | Superior, stable beyond 1100degC |

| Mechanical Strength | Lower, brittle | Higher hardness and toughness |

| Common Applications | Gate dielectrics, capacitors | Passivation layers, diffusion barriers |

| Charge Trapping | Minimal | Significant, used in charge storage devices |

| Cost | Lower, widely used | Higher, specialized uses |

Introduction to Metal-Oxides and Metal-Nitrides

Metal-oxides, composed of oxygen atoms bonded to metal elements such as aluminum oxide and titanium dioxide, exhibit excellent insulating properties and high thermal stability essential in electronics and catalysis. Metal-nitrides, including silicon nitride and titanium nitride, consist of nitrogen atoms bonded to metals, offering exceptional hardness, chemical resistance, and electrical conductivity beneficial for protective coatings and semiconductor applications. Both classes demonstrate distinct structural and electronic characteristics that define their use in advanced material technologies.

Chemical Structure and Bonding Differences

Metal-oxide compounds consist of metal cations bonded to oxygen anions, forming predominantly ionic bonds characterized by high electronegativity differences and strong ionic lattice structures. In contrast, metal-nitride materials feature metal cations bonded to nitrogen anions, where the bonding exhibits a mixed ionic-covalent character due to nitrogen's lower electronegativity compared to oxygen, resulting in stronger covalent interactions and enhanced hardness. Understanding these chemical structure and bonding differences helps tailor your material selection for applications requiring specific mechanical and electrical properties.

Electrical Properties Comparison

Metal-oxide materials typically exhibit higher dielectric constants and better electrical insulation properties compared to metal-nitride compounds, making them ideal for gate dielectrics in semiconductor devices. Metal-nitride layers offer superior thermal stability and lower leakage currents due to their strong covalent bonding and resistance to oxygen diffusion. By choosing the right material, your device's electrical performance can be optimized for reduced power consumption and improved reliability.

Thermal Stability and Conductivity

Metal-oxide materials generally exhibit higher thermal stability due to their strong ionic bonds and resistance to oxidation at elevated temperatures, making them suitable for high-temperature applications. Metal-nitride compounds boast superior electrical conductivity and thermal conductivity attributed to their covalent bonding and dense crystal structures, enhancing heat dissipation in electronic devices. Choosing between metal-oxide and metal-nitride depends on your specific needs for balancing thermal endurance and efficient heat conduction in advanced materials engineering.

Mechanical Strength and Hardness

Metal-oxide materials typically exhibit higher hardness due to their strong ionic and covalent bonding, making them more resistant to deformation and wear. Metal-nitride compounds offer superior mechanical strength with enhanced toughness and fracture resistance, attributed to their dense crystal structures and strong covalent bonds. The combination of higher hardness in metal-oxides and greater toughness in metal-nitrides is critical for applications requiring durable, abrasion-resistant coatings and structural components.

Corrosion Resistance and Durability

Metal-oxide coatings generally exhibit superior corrosion resistance due to their stable, dense oxide layer that prevents further oxidation and degradation. Metal-nitride layers offer enhanced durability with higher hardness and wear resistance, making them ideal for protective applications under mechanical stress. Your choice between metal-oxide and metal-nitride coatings should consider the specific environmental conditions and mechanical demands to maximize lifespan and protection.

Applications in Electronics and Semiconductors

Metal-oxide materials, such as silicon dioxide (SiO2), are widely used as insulating layers in semiconductor devices due to their excellent dielectric properties and thermal stability. Metal-nitride compounds like silicon nitride (Si3N4) provide superior mechanical strength and act as diffusion barriers in microelectronics, enhancing device reliability. You can optimize semiconductor performance by selecting metal-oxide for gate dielectrics and metal-nitride for protective coatings or passivation layers.

Synthesis Methods and Material Processing

Metal-oxide synthesis commonly employs sol-gel, hydrothermal, and thermal oxidation processes, offering controlled particle size and high purity, while metal-nitride synthesis primarily utilizes chemical vapor deposition (CVD), reactive sputtering, and ammonolysis for precise stoichiometry and phase control. Metal-oxide processing benefits from well-established sintering and annealing techniques to enhance crystallinity and conductivity, whereas metal-nitride materials often require high-temperature treatments under ammonia or nitrogen atmospheres to stabilize nitride phases and improve mechanical properties. Differences in chemical bonding and thermal stability dictate tailored processing parameters crucial for optimizing the functional performance of metal-oxide and metal-nitride materials in electronic and catalytic applications.

Environmental Impact and Sustainability

Metal-oxide materials generally have a lower environmental impact due to their abundance and less energy-intensive extraction processes compared to metal-nitride compounds, which often require higher energy inputs and produce more greenhouse gas emissions. The sustainability of metal-oxide applications is enhanced by their recyclability and reduced toxicity, making them preferable in eco-friendly technologies. You can support greener manufacturing by choosing metal-oxide components in your products, aligning with sustainable development goals.

Future Trends and Research Directions

Metal-oxide semiconductors continue to dominate due to their mature fabrication processes and high carrier mobility, but metal-nitride materials are gaining traction for their superior thermal stability and wide bandgap properties, making them ideal for high-power and high-frequency applications. Emerging research focuses on hybrid structures combining metal-oxides and metal-nitrides to optimize electrical performance and reliability for next-generation electronic devices. Future trends emphasize scalable deposition techniques and interface engineering to improve device endurance and reduce leakage currents in metal-oxide and metal-nitride based components.

Metal-Oxide vs Metal-Nitride Infographic

libmatt.com

libmatt.com