TGV trains offer high-speed travel across long distances in France, featuring widespread routes and frequent service, whereas TSV typically refers to "Transport Semi-Vitesse," a slower or regional train service with fewer amenities and limited coverage. Your choice depends on whether you prioritize speed and connectivity (TGV) or cost and regional access (TSV).

Table of Comparison

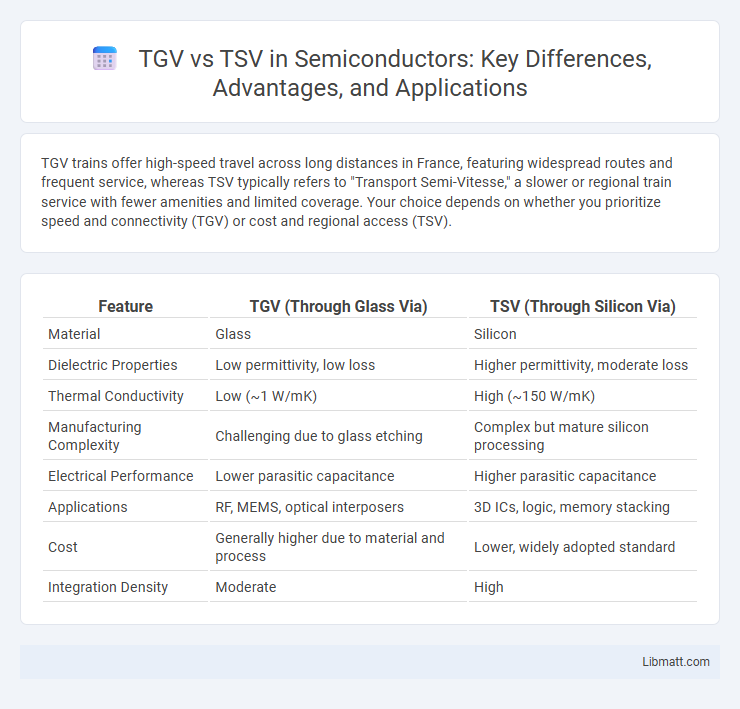

| Feature | TGV (Through Glass Via) | TSV (Through Silicon Via) |

|---|---|---|

| Material | Glass | Silicon |

| Dielectric Properties | Low permittivity, low loss | Higher permittivity, moderate loss |

| Thermal Conductivity | Low (~1 W/mK) | High (~150 W/mK) |

| Manufacturing Complexity | Challenging due to glass etching | Complex but mature silicon processing |

| Electrical Performance | Lower parasitic capacitance | Higher parasitic capacitance |

| Applications | RF, MEMS, optical interposers | 3D ICs, logic, memory stacking |

| Cost | Generally higher due to material and process | Lower, widely adopted standard |

| Integration Density | Moderate | High |

Overview: Understanding TGV and TSV Technologies

TGV (Through-Glass Via) and TSV (Through-Silicon Via) technologies enable vertical electrical connections within semiconductor devices, improving performance and miniaturization. TGV is primarily used in glass substrates offering excellent electrical insulation and optical transparency, while TSV involves silicon substrates, providing superior thermal conductivity and mechanical strength. Both technologies are pivotal for 3D integrated circuits and heterogeneous integration in advanced packaging solutions.

Definition and Key Differences Between TGV and TSV

TGV (Transposon-Gene Variant) and TSV (Transposon Sequence Variant) differ primarily in their genomic context and function; TGVs refer to variations within transposon-adjacent genes affecting gene expression, while TSVs are variations within the transposon sequences themselves impacting transposon mobility and regulation. TGVs can influence phenotypic traits by altering gene function, whereas TSVs mainly affect transposon activity and genome stability. Understanding these key differences helps you interpret their roles in genetic diversity and genome evolution.

Technical Structure of TGV (Through-Glass Via)

The technical structure of TGV (Through-Glass Via) consists of vertical electrical connections that pass directly through a glass substrate, enabling high-density and high-speed interconnections in advanced semiconductor packaging. TGVs offer superior electrical insulation and low dielectric loss compared to TSVs (Through-Silicon Vias), which traverse silicon substrates and can introduce higher parasitic capacitance. Your choice between TGV and TSV will depend on the specific performance requirements and material properties needed for your electronic device.

Technical Structure of TSV (Through-Silicon Via)

TSV (Through-Silicon Via) is a vertical electrical connection that passes through a silicon wafer or die, enabling high-density 3D integration in semiconductor devices. Its technical structure consists of a cylindrical via etched through the silicon substrate, lined with an insulating dielectric layer, and filled with conductive materials such as copper or tungsten to ensure efficient signal transmission and thermal management. Unlike TGV (Through-Glass Via), TSV offers lower resistance and capacitance due to the conductive copper filling and direct silicon integration, enhancing performance in advanced microelectronics and packaging.

Manufacturing Processes: TGV vs TSV

TGV (Through Glass Via) manufacturing involves laser drilling precise holes in glass substrates, followed by metal deposition and plating to create vertical interconnections with superior insulation and thermal stability. TSV (Through Silicon Via) processes require deep silicon etching, dielectric liner deposition, and copper filling, demanding complex handling due to silicon's mechanical fragility and electrical conductivity. Your choice between TGV and TSV impacts manufacturing speed, cost, and integration capabilities in advanced semiconductor packaging.

Performance Comparison: Electrical and Thermal Properties

TGV (Through-Glass Via) and TSV (Through-Silicon Via) technologies differ significantly in electrical and thermal performance characteristics. TSVs typically offer lower electrical resistance and inductance due to silicon's higher conductivity, enabling faster signal transmission and improved power delivery, whereas TGVs, embedded in glass, provide superior insulation and reduced parasitic capacitance, enhancing signal integrity. Thermally, TSVs display better heat dissipation capabilities because silicon has higher thermal conductivity compared to glass, making TSVs more suitable for high-power applications, while TGVs excel in minimizing thermal-induced stress due to glass's stable thermal expansion coefficient.

Application Areas: Where TGV and TSV Are Used

TGV (Through Glass Via) is widely utilized in advanced semiconductor packaging, particularly in 3D integrated circuits and high-frequency applications due to its superior electrical performance and thermal management. TSV (Through Silicon Via) dominates in memory stacking, heterogeneous integration, and system-on-chip designs, enabling shorter interconnects and enhanced performance in mobile devices, data centers, and AI processors. Your choice between TGV and TSV depends on specific application needs, such as the material compatibility and performance requirements of your electronic system.

Advantages and Limitations of TGV

TGV (Tubular Goods with Vertical profile) offers superior structural stability and easier installation compared to TSV (Through-Silicon Via), making it advantageous for high-performance electronic packaging applications. Its vertical orientation allows efficient heat dissipation and enhanced electrical performance, but fabrication complexity and higher manufacturing costs limit widespread adoption. Your choice depends on whether the benefits in thermal management and signal integrity outweigh the increased production challenges associated with TGV technology.

Advantages and Limitations of TSV

TSV (Through-Silicon Via) technology offers significant advantages over traditional TGV (Through-Glass Via) by providing higher integration density and improved electrical performance due to shorter interconnect lengths and better thermal conductivity in silicon substrates. Limitations of TSV include increased fabrication complexity and cost, potential stress-induced wafer warping, and challenges in mitigating signal crosstalk and reliability issues under thermal cycling. Despite these drawbacks, TSV remains a preferred solution for 3D integrated circuits demanding high bandwidth and low latency interconnections.

Future Trends: The Evolving Role of TGV and TSV in Microelectronics

Future trends in microelectronics highlight the complementary roles of TGV (Through Glass Via) and TSV (Through Silicon Via) technologies in enabling higher device integration and enhanced performance. TGV offers superior electrical insulation and reduced parasitic capacitance ideal for RF and optoelectronic applications, while TSV continues to dominate 3D IC stacking due to its silicon compatibility and thermal management capabilities. Your microelectronics designs will benefit from leveraging the evolving synergy between TGV and TSV for optimized signal integrity and miniaturization in next-generation devices.

TGV vs TSV Infographic

libmatt.com

libmatt.com