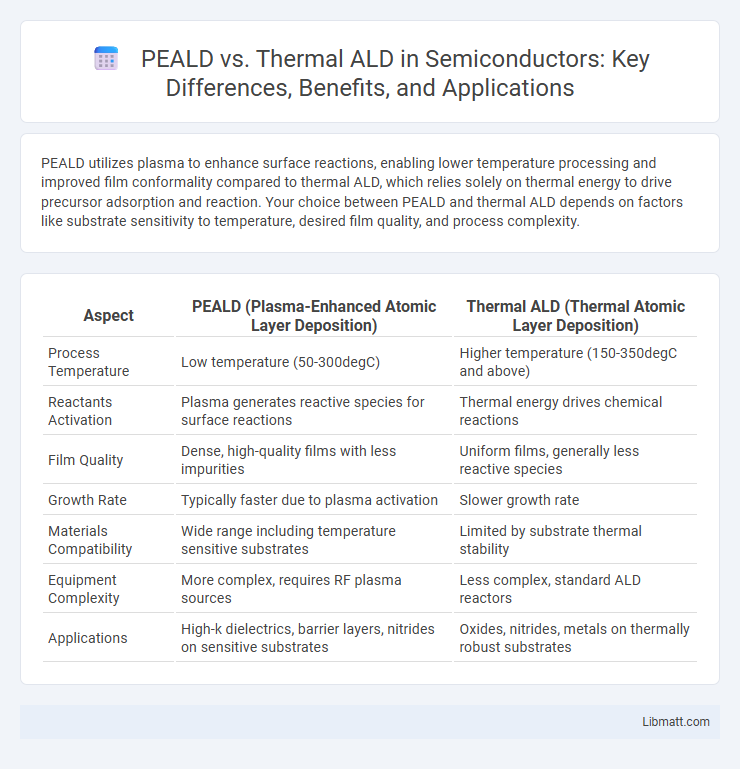

PEALD utilizes plasma to enhance surface reactions, enabling lower temperature processing and improved film conformality compared to thermal ALD, which relies solely on thermal energy to drive precursor adsorption and reaction. Your choice between PEALD and thermal ALD depends on factors like substrate sensitivity to temperature, desired film quality, and process complexity.

Table of Comparison

| Aspect | PEALD (Plasma-Enhanced Atomic Layer Deposition) | Thermal ALD (Thermal Atomic Layer Deposition) |

|---|---|---|

| Process Temperature | Low temperature (50-300degC) | Higher temperature (150-350degC and above) |

| Reactants Activation | Plasma generates reactive species for surface reactions | Thermal energy drives chemical reactions |

| Film Quality | Dense, high-quality films with less impurities | Uniform films, generally less reactive species |

| Growth Rate | Typically faster due to plasma activation | Slower growth rate |

| Materials Compatibility | Wide range including temperature sensitive substrates | Limited by substrate thermal stability |

| Equipment Complexity | More complex, requires RF plasma sources | Less complex, standard ALD reactors |

| Applications | High-k dielectrics, barrier layers, nitrides on sensitive substrates | Oxides, nitrides, metals on thermally robust substrates |

Introduction to Atomic Layer Deposition (ALD)

Atomic Layer Deposition (ALD) is a thin film deposition technique known for its precise atomic-scale control and uniform coating on complex substrates. Plasma-Enhanced ALD (PEALD) utilizes plasma to generate reactive species, enabling lower temperature processing and enhanced film quality compared to Thermal ALD, which relies solely on thermal energy for surface reactions. Your choice between PEALD and Thermal ALD depends on substrate sensitivity and desired film properties.

Overview of Plasma-Enhanced ALD (PEALD)

Plasma-Enhanced Atomic Layer Deposition (PEALD) utilizes plasma to generate highly reactive species, enabling lower temperature deposition and improved film conformality compared to Thermal ALD. The plasma source enhances precursor surface reactions, resulting in denser, purer thin films ideal for advanced semiconductor manufacturing and flexible electronics. PEALD offers increased process flexibility and material compatibility, making it suitable for high-aspect-ratio structures and temperature-sensitive substrates.

Fundamentals of Thermal ALD

Thermal Atomic Layer Deposition (ALD) relies on sequential, self-limiting surface reactions between gaseous precursors and a substrate, ensuring precise thickness control at the atomic scale. This process operates at elevated temperatures, typically between 150degC and 350degC, which activates chemical reactions without plasma assistance. Your choice between Thermal ALD and Plasma-Enhanced ALD (PEALD) depends on factors like film conformity, material properties, and temperature sensitivity, with Thermal ALD offering excellent film uniformity through purely thermal reactions.

Key Differences Between PEALD and Thermal ALD

PEALD (Plasma-Enhanced Atomic Layer Deposition) utilizes plasma to activate chemical reactions at lower temperatures, enabling precise thin-film growth on temperature-sensitive substrates, whereas Thermal ALD relies solely on thermal energy to drive surface reactions, often requiring higher temperatures. The plasma in PEALD enhances reactivity and film conformality, leading to improved film density and reduced defect levels, while Thermal ALD typically offers better uniformity on complex 3D structures due to its surface saturation mechanism. Your choice between PEALD and Thermal ALD depends on factors such as substrate sensitivity, required film properties, and process temperature constraints.

Comparative Process Conditions: Temperature and Pressure

Plasma-Enhanced Atomic Layer Deposition (PEALD) typically operates at lower temperatures, often between 50degC and 300degC, compared to Thermal Atomic Layer Deposition (ALD), which usually requires higher temperatures ranging from 150degC to 400degC. PEALD utilizes plasma to generate reactive species, enabling deposition at reduced pressures and enhancing film quality on temperature-sensitive substrates. Your choice between PEALD and Thermal ALD depends on the specific thermal budget and pressure constraints of the application, with PEALD offering greater flexibility for delicate materials.

Material Compatibility and Film Quality

PEALD offers superior material compatibility with temperature-sensitive substrates due to its low thermal budget, enabling deposition on polymers and flexible electronics without damage. Film quality in PEALD is enhanced by plasma-assisted reactions that produce denser, more uniform films with reduced impurities compared to thermal ALD. Your choice between PEALD and thermal ALD depends on the specific material system and desired film properties, where PEALD provides greater versatility and high-quality thin films for advanced applications.

Throughput and Deposition Rates

Plasma-Enhanced Atomic Layer Deposition (PEALD) offers higher deposition rates compared to Thermal ALD due to the enhanced reactivity of plasma species, which accelerates surface chemical reactions. This increased reaction rate translates to improved throughput, making PEALD suitable for applications requiring faster film growth without sacrificing atomic-level control. Your choice between PEALD and Thermal ALD should consider that PEALD typically achieves throughput up to 2-3 times greater under similar conditions.

Application Areas: PEALD vs Thermal ALD

Plasma-Enhanced Atomic Layer Deposition (PEALD) excels in applications requiring low-temperature processing, such as flexible electronics and temperature-sensitive substrates, by enabling high-quality thin films with improved surface reactivity. Thermal ALD is preferred for semiconductor device fabrication and high-precision coating in microelectronics where thermal stability and conformality over complex topographies are critical. Your choice between PEALD and Thermal ALD should consider the substrate sensitivity and desired film properties in applications like photovoltaics, MEMS, and advanced coatings.

Challenges and Limitations of Each Technique

PEALD faces challenges including plasma-induced damage to sensitive substrates and limited penetration in high aspect ratio structures, restricting uniform film growth. Thermal ALD struggles with lower reactivity at reduced temperatures, leading to slower deposition rates and possible precursor decomposition. Both techniques are limited by precursor availability and compatibility, impacting the quality and scalability of thin-film deposition.

Future Trends in ALD Technology

Plasma-Enhanced Atomic Layer Deposition (PEALD) offers faster deposition rates and lower temperature processes compared to Thermal ALD, making it ideal for next-generation semiconductor applications. Future trends in ALD technology emphasize hybrid techniques combining PEALD and Thermal ALD to optimize film quality, conformality, and throughput for advanced device architectures. Your choice between these methods will increasingly depend on the balance of process temperature constraints and desired material properties in emerging nanotechnology fields.

PEALD vs Thermal ALD Infographic

libmatt.com

libmatt.com