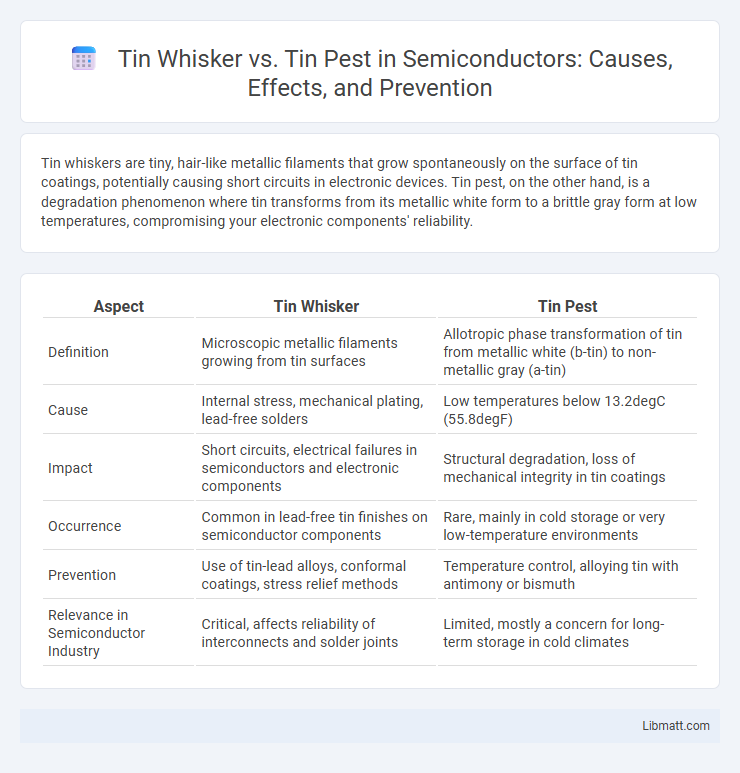

Tin whiskers are tiny, hair-like metallic filaments that grow spontaneously on the surface of tin coatings, potentially causing short circuits in electronic devices. Tin pest, on the other hand, is a degradation phenomenon where tin transforms from its metallic white form to a brittle gray form at low temperatures, compromising your electronic components' reliability.

Table of Comparison

| Aspect | Tin Whisker | Tin Pest |

|---|---|---|

| Definition | Microscopic metallic filaments growing from tin surfaces | Allotropic phase transformation of tin from metallic white (b-tin) to non-metallic gray (a-tin) |

| Cause | Internal stress, mechanical plating, lead-free solders | Low temperatures below 13.2degC (55.8degF) |

| Impact | Short circuits, electrical failures in semiconductors and electronic components | Structural degradation, loss of mechanical integrity in tin coatings |

| Occurrence | Common in lead-free tin finishes on semiconductor components | Rare, mainly in cold storage or very low-temperature environments |

| Prevention | Use of tin-lead alloys, conformal coatings, stress relief methods | Temperature control, alloying tin with antimony or bismuth |

| Relevance in Semiconductor Industry | Critical, affects reliability of interconnects and solder joints | Limited, mostly a concern for long-term storage in cold climates |

Introduction to Tin Whisker and Tin Pest

Tin whisker refers to tiny, hair-like metallic filaments that spontaneously grow from tin surfaces, causing electrical shorts and component failures in electronic devices. Tin pest, also known as tin disease, is a low-temperature allotropic transformation of white tin into brittle gray tin, leading to material disintegration in cold environments. Both phenomena pose significant reliability challenges in electronics and materials engineering, necessitating careful consideration in tin-based component design and usage.

Defining Tin Whisker: Causes and Characteristics

Tin Whisker is a microscopic, hair-like metallic filament that grows spontaneously from the surface of tin coatings, often caused by mechanical stress, impurities, or environmental factors such as humidity and temperature fluctuations. These whiskers can lead to short circuits and failures in electronic components due to their conductive properties and unpredictable growth patterns. Understanding the causes and characteristics of Tin Whisker is crucial for mitigating risks in sensitive electronic devices and ensuring the reliability of your tin-plated connections.

Understanding Tin Pest: Mechanism and Triggers

Tin pest occurs when gray tin forms from white tin at low temperatures, typically below 13.2degC, causing structural disintegration due to a phase transformation. This mechanism involves atomic rearrangement, leading to expansion and embrittlement, which compromises the integrity of tin-coated materials. Understanding these triggers helps you prevent failures in electronic components exposed to cold environments.

Key Differences between Tin Whisker and Tin Pest

Tin whiskers are tiny, hair-like metallic filaments that grow spontaneously from the surface of tin coatings, causing short circuits in electronic components, while tin pest is a phase transformation of tin and results in the brittle, powdery form of the metal at low temperatures. Tin whisker growth primarily affects electronic reliability by creating conductive paths, whereas tin pest leads to structural degradation and mechanical failure in tin materials. Understanding these key differences helps you mitigate the risks in electronics manufacturing and storage environments.

Impact on Electronic Components

Tin whiskers cause short circuits and reliability failures in electronic components by growing tiny, conductive filaments that bridge circuit paths under stress. Tin pest leads to the disintegration and loss of mechanical integrity in tin-plated parts when exposed to low temperatures, resulting in component malfunction or failure. Understanding these phenomena helps you mitigate risks in critical electronics used in aerospace, automotive, and medical devices.

Factors Influencing Tin Whisker Formation

Tin whisker formation is primarily influenced by mechanical stress, temperature fluctuations, and the presence of intermetallic compounds, especially in pure tin or tin-rich coatings. The crystal structure changes and grain boundary dynamics under stress cause metal atoms to migrate, leading to whisker growth. Unlike tin pest, which occurs due to low-temperature phase transformation, tin whiskers arise from stress-induced migration, posing significant reliability risks in electronic components.

Conditions Promoting Tin Pest Development

Tin pest develops primarily under extremely low temperatures, typically below 13degC (55degF), where the metallic white beta-tin transforms into brittle gray alpha-tin. High humidity and prolonged exposure to cold conditions accelerate this allotropic phase change, causing structural degradation in tin coatings. Your electronic components stored or operated in cold, damp environments are more susceptible to tin pest, leading to potential failure due to cracking and loss of conductivity.

Detection and Diagnosis Methods

Detection and diagnosis of tin whiskers primarily involve high-resolution electron microscopy techniques such as scanning electron microscopy (SEM) to visualize fine metallic filaments on tin surfaces. For tin pest, low-temperature exposure tests coupled with X-ray diffraction (XRD) and optical microscopy are used to identify the phase transformation from metallic tin (white tin) to brittle gray tin. Advanced nondestructive evaluation methods including acoustic emission and electrical resistance monitoring also aid in early detection of these tin-related failures in electronic components.

Mitigation and Prevention Strategies

Mitigation and prevention strategies for tin whisker and tin pest involve selecting appropriate materials and implementing controlled environmental conditions. Applying conformal coatings and using alloyed tin with small amounts of lead or other elements can reduce tin whisker growth, while maintaining low temperatures and avoiding rapid cooling cycles help prevent tin pest formation. Your electronic components benefit from rigorous testing and continuous monitoring to ensure long-term reliability in challenging environments.

Future Trends and Research in Tin Corrosion Phenomena

Future research in tin corrosion phenomena emphasizes advanced materials science techniques to mitigate tin whisker growth and tin pest formation. Emerging studies focus on nanoscale characterization and novel alloying strategies to enhance the reliability of electronic components exposed to extreme conditions. You can expect innovations in microstructural control and environmental testing to play a critical role in preventing these tin-related failures in next-generation electronic devices.

Tin Whisker vs Tin Pest Infographic

libmatt.com

libmatt.com