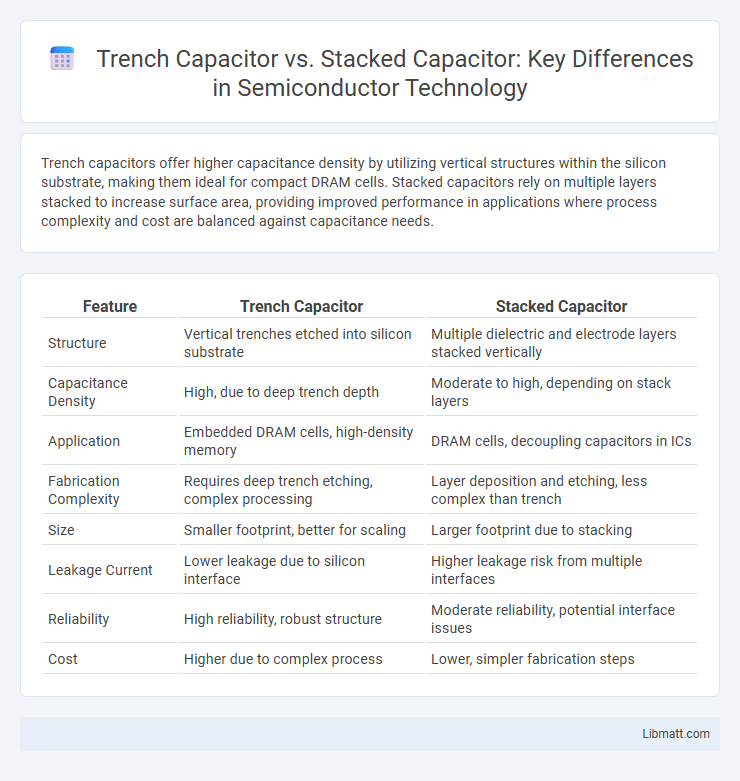

Trench capacitors offer higher capacitance density by utilizing vertical structures within the silicon substrate, making them ideal for compact DRAM cells. Stacked capacitors rely on multiple layers stacked to increase surface area, providing improved performance in applications where process complexity and cost are balanced against capacitance needs.

Table of Comparison

| Feature | Trench Capacitor | Stacked Capacitor |

|---|---|---|

| Structure | Vertical trenches etched into silicon substrate | Multiple dielectric and electrode layers stacked vertically |

| Capacitance Density | High, due to deep trench depth | Moderate to high, depending on stack layers |

| Application | Embedded DRAM cells, high-density memory | DRAM cells, decoupling capacitors in ICs |

| Fabrication Complexity | Requires deep trench etching, complex processing | Layer deposition and etching, less complex than trench |

| Size | Smaller footprint, better for scaling | Larger footprint due to stacking |

| Leakage Current | Lower leakage due to silicon interface | Higher leakage risk from multiple interfaces |

| Reliability | High reliability, robust structure | Moderate reliability, potential interface issues |

| Cost | Higher due to complex process | Lower, simpler fabrication steps |

Introduction to Capacitor Technologies

Trench capacitors utilize deep, vertical trenches etched into silicon to increase surface area, enabling high capacitance within a smaller footprint ideal for DRAM applications. Stacked capacitors consist of multiple layers built above the substrate, leveraging vertical scaling and complex geometries to enhance capacitance while maintaining planar integration. Both technologies address miniaturization challenges in semiconductor memory by optimizing dielectric properties and electrode surface areas for improved charge storage.

Overview of Trench Capacitors

Trench capacitors are integrated capacitors that utilize deep vertical trenches etched into the silicon substrate to significantly increase surface area, enabling higher capacitance values in a compact footprint. Commonly employed in DRAM cells, these capacitors offer superior charge storage capabilities compared to planar designs, enhancing memory density and performance. Their structure reduces parasitic resistance and improves leakage characteristics, making them ideal for advanced semiconductor applications.

Overview of Stacked Capacitors

Stacked capacitors are advanced DRAM storage elements composed of multiple layers of capacitor structures arranged vertically to maximize capacitance within a limited footprint. These capacitors utilize high-k dielectric materials and metal-insulator-metal (MIM) configurations to enhance charge storage efficiency and reduce leakage current. Compared to trench capacitors, stacked capacitors offer increased scalability and improved integration with CMOS processes, enabling higher memory densities in modern semiconductor devices.

Structural Differences: Trench vs Stacked Capacitors

Trench capacitors feature a vertical structure with deep, narrow trenches etched into the silicon substrate, increasing surface area and capacitance in a compact footprint. Stacked capacitors employ multiple layers of dielectric and conductive materials stacked horizontally above the substrate, maximizing capacitance without extending into the silicon. The primary structural difference lies in trench capacitors utilizing substrate depth, whereas stacked capacitors build capacitance through layered vertical stacks on the surface.

Fabrication Process Comparison

Trench capacitors are fabricated by etching deep vertical trenches into the silicon substrate followed by doping and dielectric layer deposition, enabling high capacitance density in a small footprint. Stacked capacitors, in contrast, are constructed by depositing multiple layers of polysilicon and dielectric films on the substrate surface, increasing capacitance through vertical layering rather than substrate etching. The trench process involves complex deep reactive-ion etching (DRIE) and isotropic doping steps, while the stacked process relies on precise thin-film deposition and planarization techniques.

Performance and Efficiency Evaluation

Trench capacitors offer superior performance in terms of capacitance density and leakage current reduction, making them highly efficient for dynamic random-access memory (DRAM) applications. Stacked capacitors provide enhanced dielectric properties and better scalability in three-dimensional structures, resulting in improved charge storage capacity at smaller geometries. Evaluations indicate trench capacitors excel in minimizing parasitic resistances, while stacked capacitors deliver higher overall energy efficiency in advanced semiconductor technologies.

Applications in Modern Semiconductor Devices

Trench capacitors offer high capacitance density and are widely used in DRAM cells for compact memory storage, while stacked capacitors provide larger surface areas suitable for non-volatile memories like FLASH. Your choice between trench and stacked capacitors depends on device requirements such as scaling, retention, and integration complexity. Modern semiconductor devices leverage trench capacitors for high-speed, low-leakage applications and stacked capacitors where larger charge storage is critical.

Advantages of Trench Capacitors

Trench capacitors offer superior capacitance density by utilizing vertical structures that maximize surface area within a smaller footprint, making them ideal for high-density DRAM applications. Their deep trench design reduces parasitic resistance and capacitance, enhancing overall device speed and power efficiency. You benefit from improved integration and reduced chip size, which supports advanced miniaturization in semiconductor manufacturing.

Advantages of Stacked Capacitors

Stacked capacitors provide a higher capacitance density compared to trench capacitors, making them ideal for achieving larger charge storage in limited chip area. Their planar structure simplifies fabrication and enhances yield by reducing process complexity and defects. You benefit from improved scalability and integration flexibility, which supports advanced semiconductor device performance.

Future Trends in DRAM Capacitor Design

Future trends in DRAM capacitor design emphasize increased storage density and improved electrical performance, with trench capacitors offering superior surface area integration through vertical etching techniques. Stacked capacitors continue to evolve by incorporating high-k dielectric materials and advanced 3D structuring to minimize leakage and enhance capacitance. Innovations in materials science and nanofabrication are driving a shift toward hybrid capacitor architectures that combine the benefits of trench and stacked designs for next-generation memory solutions.

Trench Capacitor vs Stacked Capacitor Infographic

libmatt.com

libmatt.com