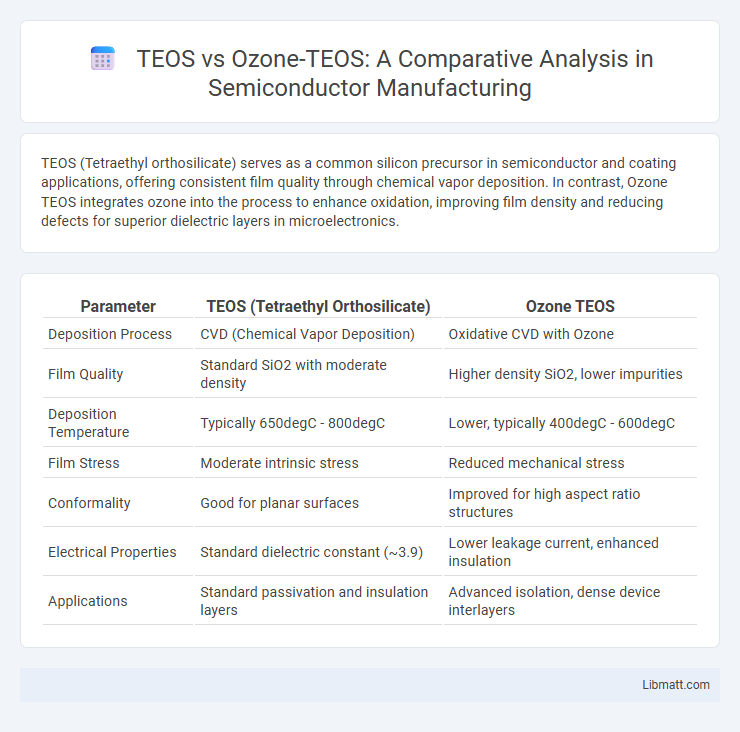

TEOS (Tetraethyl orthosilicate) serves as a common silicon precursor in semiconductor and coating applications, offering consistent film quality through chemical vapor deposition. In contrast, Ozone TEOS integrates ozone into the process to enhance oxidation, improving film density and reducing defects for superior dielectric layers in microelectronics.

Table of Comparison

| Parameter | TEOS (Tetraethyl Orthosilicate) | Ozone TEOS |

|---|---|---|

| Deposition Process | CVD (Chemical Vapor Deposition) | Oxidative CVD with Ozone |

| Film Quality | Standard SiO2 with moderate density | Higher density SiO2, lower impurities |

| Deposition Temperature | Typically 650degC - 800degC | Lower, typically 400degC - 600degC |

| Film Stress | Moderate intrinsic stress | Reduced mechanical stress |

| Conformality | Good for planar surfaces | Improved for high aspect ratio structures |

| Electrical Properties | Standard dielectric constant (~3.9) | Lower leakage current, enhanced insulation |

| Applications | Standard passivation and insulation layers | Advanced isolation, dense device interlayers |

Introduction to TEOS and Ozone TEOS

TEOS, or tetraethyl orthosilicate, is a common silicon source used in semiconductor manufacturing for thin film deposition, providing high purity and uniformity. Ozone TEOS enhances this process by incorporating ozone as an oxidizing agent, resulting in improved film density and reduced deposition temperature. Your choice between TEOS and Ozone TEOS impacts film quality and process efficiency in advanced microfabrication.

Chemical Structure and Properties Comparison

TEOS (Tetraethyl Orthosilicate) has a molecular formula of Si(OC2H5)4, featuring a silicon atom tetrahedrally bonded to four ethoxy groups, making it a clear, volatile liquid used as a precursor in sol-gel processes. Ozone TEOS refers to TEOS treated or reacted with ozone (O3), leading to oxidation of ethoxy groups and potential formation of silanol groups, enhancing hydrophilicity and reactivity. Your choice between TEOS and ozone-modified TEOS influences the surface chemical properties, reaction kinetics, and overall durability of the resulting silica-based materials.

Synthesis and Processing Methods

TEOS (Tetraethyl Orthosilicate) is synthesized primarily through the condensation of silicon tetrachloride with ethanol in the presence of a catalyst, resulting in a precursor widely used in sol-gel processes for thin films and coatings. Ozone TEOS combines TEOS with ozone treatment, enhancing hydrolysis rates and promoting more uniform silica network formation during synthesis, leading to improved material homogeneity. Your selection between TEOS and Ozone TEOS depends on the desired processing speed and film quality, as ozone-assisted methods typically require shorter processing times and yield denser oxide layers.

Deposition Mechanisms: TEOS vs Ozone TEOS

TEOS (Tetraethyl orthosilicate) deposition primarily relies on thermal decomposition and surface chemisorption to form silicon dioxide films, whereas Ozone TEOS enhances this process by introducing ozone as an oxidizing agent, resulting in more reactive oxygen species that improve film density and uniformity. The Ozone TEOS mechanism facilitates lower temperature deposition with reduced carbon contamination compared to conventional TEOS, due to the efficient oxidation of organic byproducts. This difference in deposition mechanisms enables Ozone TEOS to achieve superior dielectric properties and conformal coverage, particularly beneficial for advanced semiconductor manufacturing.

Film Quality and Purity Differences

TEOS (Tetraethyl Orthosilicate) deposited films often exhibit higher purity with fewer carbon contaminants compared to Ozone TEOS, which can introduce more hydroxyl groups affecting dielectric properties. Ozone TEOS typically enables denser films with improved step coverage and reduced hydrogen content, enhancing mechanical strength and electrical performance in advanced semiconductor applications. The choice between TEOS and Ozone TEOS processes directly impacts film quality, with Ozone TEOS favored for high-quality silicon dioxide layers requiring superior uniformity and lower impurities.

Role in Semiconductor Manufacturing

TEOS (Tetraethyl Orthosilicate) serves as a critical silicon source in semiconductor manufacturing, especially for depositing silicon dioxide (SiO2) layers through chemical vapor deposition (CVD). Ozone TEOS enhances the TEOS process by introducing ozone, which improves oxide film quality with superior density and electrical properties, crucial for ultra-thin dielectric layers in advanced semiconductor devices. Your choice between TEOS and Ozone TEOS impacts device performance, with Ozone TEOS favored for high-precision applications requiring enhanced film uniformity and reduced defects.

Thermal and Electrical Performance

TEOS (Tetraethyl Orthosilicate) films exhibit stable thermal insulation properties with moderate dielectric constants around 4.0, ensuring efficient electrical performance in microelectronic applications. Ozone TEOS, enhanced by ozone oxidation during deposition, produces films with lower impurity content and higher density, resulting in improved thermal stability and reduced dielectric constant (~3.8), which supports better electrical insulation and reduced signal delay. Your device's performance benefits from Ozone TEOS through enhanced thermal resistance and superior electrical characteristics, making it preferable for advanced integrated circuits requiring low-k dielectrics.

Environmental and Safety Considerations

TEOS (Tetraethyl orthosilicate) and ozone TEOS processes differ significantly in environmental and safety profiles, with ozone TEOS offering a cleaner alternative by reducing the use of hazardous chemicals and lowering volatile organic compound (VOC) emissions. TEOS requires careful handling due to its flammability and toxicity, posing risks such as respiratory irritation and environmental contamination if not managed properly. Your choice between these methods should consider regulatory compliance, minimizing health hazards, and the environmental impact of solvent usage and byproduct generation.

Cost and Scalability Analysis

TEOS (Tetraethyl Orthosilicate) generally offers lower raw material costs compared to ozone TEOS due to its simpler synthesis process and widespread availability. Scalability of TEOS is advantageous for large-scale industrial applications, with established supply chains supporting high-volume production that reduces per-unit costs. In contrast, ozone TEOS, while potentially delivering higher purity films, faces higher operational costs and scalability challenges due to specialized ozone generation equipment and stricter safety protocols.

Future Trends in Thin Film Deposition Techniques

Future trends in thin film deposition highlight a growing preference for Ozone TEOS over traditional TEOS due to its enhanced film quality and lower impurity levels. Ozone TEOS enables more efficient silicon dioxide layer formation with improved dielectric properties and reduced thermal budgets, aligning with the semiconductor industry's push for miniaturization and high-performance devices. Advances in atomic layer deposition (ALD) further integrate Ozone TEOS to achieve ultra-thin, uniform films critical for next-generation electronics and emerging nanotechnologies.

TEOS vs Ozone TEOS Infographic

libmatt.com

libmatt.com