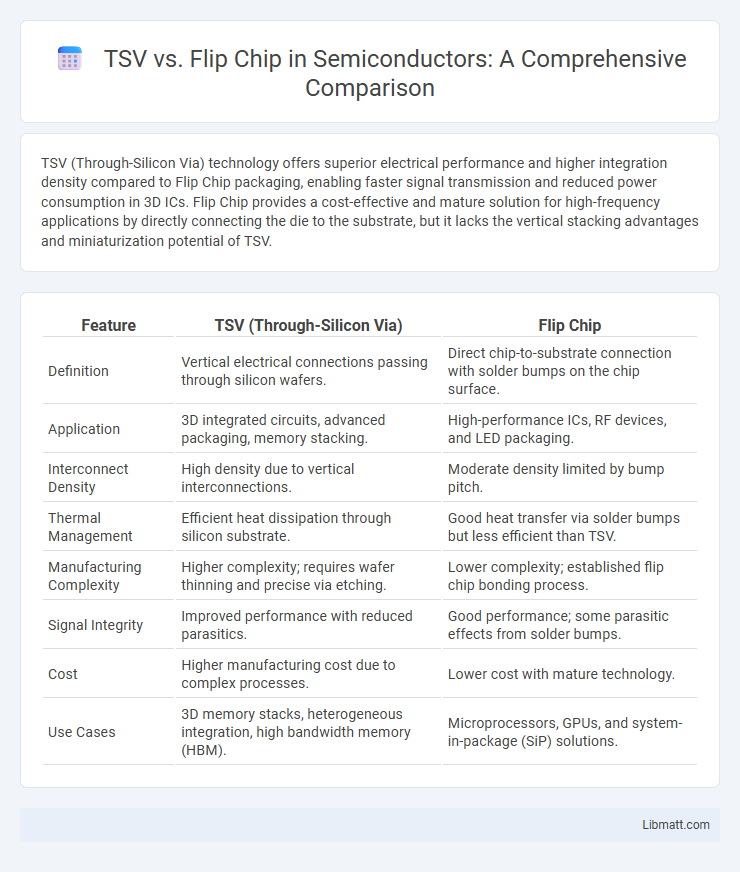

TSV (Through-Silicon Via) technology offers superior electrical performance and higher integration density compared to Flip Chip packaging, enabling faster signal transmission and reduced power consumption in 3D ICs. Flip Chip provides a cost-effective and mature solution for high-frequency applications by directly connecting the die to the substrate, but it lacks the vertical stacking advantages and miniaturization potential of TSV.

Table of Comparison

| Feature | TSV (Through-Silicon Via) | Flip Chip |

|---|---|---|

| Definition | Vertical electrical connections passing through silicon wafers. | Direct chip-to-substrate connection with solder bumps on the chip surface. |

| Application | 3D integrated circuits, advanced packaging, memory stacking. | High-performance ICs, RF devices, and LED packaging. |

| Interconnect Density | High density due to vertical interconnections. | Moderate density limited by bump pitch. |

| Thermal Management | Efficient heat dissipation through silicon substrate. | Good heat transfer via solder bumps but less efficient than TSV. |

| Manufacturing Complexity | Higher complexity; requires wafer thinning and precise via etching. | Lower complexity; established flip chip bonding process. |

| Signal Integrity | Improved performance with reduced parasitics. | Good performance; some parasitic effects from solder bumps. |

| Cost | Higher manufacturing cost due to complex processes. | Lower cost with mature technology. |

| Use Cases | 3D memory stacks, heterogeneous integration, high bandwidth memory (HBM). | Microprocessors, GPUs, and system-in-package (SiP) solutions. |

Introduction to TSV and Flip Chip Technologies

Through-Silicon Via (TSV) technology enables vertical electrical connections by passing through silicon wafers, significantly enhancing interconnect density and performance in 3D integrated circuits. Flip Chip technology involves flipping the semiconductor die to directly connect it to the substrate using solder bumps, providing improved electrical performance and thermal management compared to traditional wire bonding. Your choice between TSV and Flip Chip depends on the specific application requirements, such as scaling, signal speed, and thermal dissipation needs.

Overview of Advanced Packaging Techniques

TSV (Through-Silicon Via) and Flip Chip are advanced semiconductor packaging techniques enhancing device performance and miniaturization. TSV enables vertical electrical connections through silicon wafers, improving integration and reducing latency, while Flip Chip mounts the chip directly onto the substrate using solder bumps, enhancing signal transmission and thermal management. Your choice between these methods depends on application requirements, balancing factors like complexity, cost, and electrical efficiency.

Technical Architecture: TSV vs Flip Chip

Through-Silicon Via (TSV) technology employs vertical electrical connections that pass directly through the silicon substrate, enabling high-density 3D integration and reduced signal path length for enhanced performance. Flip Chip packaging attaches the chip face-down onto the substrate using solder bumps, facilitating a high I/O count and excellent thermal dissipation but limited to 2.5D integration. TSV's vertical stacking offers superior bandwidth and power efficiency for advanced applications compared to Flip Chip's planar architecture, which is more suited for cost-effective, conventional interconnect solutions.

Material and Design Considerations

TSV (Through-Silicon Via) technology incorporates vertical electrical connections passing directly through silicon wafers, using copper or tungsten to achieve high-density interconnects and reduced signal delay. Flip Chip design relies on solder bumps or microbumps made from materials like lead-free solder alloys or copper pillars, enabling direct electrical contact between the die and substrate for improved electrical performance and thermal dissipation. Material choices in TSV focus on minimizing thermal expansion mismatch with silicon to maintain structural integrity, while Flip Chip design emphasizes bump pitch and underfill materials for mechanical reliability and stress distribution.

Performance Comparison: Speed, Power, and Reliability

TSV (Through-Silicon Via) technology enhances speed by providing shorter interconnects and reducing signal delay compared to Flip Chip packaging, which relies on longer, lateral routes. Power efficiency in TSV is improved due to lower parasitic capacitance and resistance, leading to reduced energy consumption, whereas Flip Chip may suffer from higher power leakage. Reliability-wise, TSV exhibits superior mechanical stability under thermal stress and vibration, minimizing failures often seen in Flip Chip bumps and solder joints.

Manufacturing Process Differences

TSV (Through-Silicon Via) involves creating vertical electrical connections by etching holes through silicon wafers, filled with conductive materials to enable 3D stacking of dies, whereas Flip Chip technology uses solder bumps on the chip surface to connect directly to the substrate or PCB, enabling high-density interconnects on a two-dimensional plane. TSV manufacturing requires complex wafer thinning, via etching, and precise filling, incorporating additional steps like wafer bonding and alignment for stacked dies. Flip Chip production focuses on bump deposition, under bump metallization, and flip chip placement, emphasizing surface mount techniques rather than through-substrate integration seen in TSV.

Cost Analysis and Economic Impact

TSV (Through-Silicon Via) technology incurs higher initial manufacturing costs due to complex fabrication processes and advanced equipment requirements, impacting overall project budgets significantly. Flip Chip offers a more cost-effective solution with simpler assembly and established production lines, reducing per-unit expenses and accelerating time-to-market. Your choice between TSV and Flip Chip will directly influence the economic feasibility and scalability of your semiconductor device production.

Application Areas: Where TSV and Flip Chip Excel

TSV technology excels in high-performance computing, 3D integrated circuits, and advanced memory stacks due to its ability to provide vertical interconnections with minimal latency and power consumption. Flip chip is widely used in consumer electronics, automotive sensors, and LED packaging for its cost-effective assembly and reliable electrical performance. For your specific project, choosing between TSV and flip chip depends on the integration density and thermal management requirements.

Challenges and Future Trends in Packaging Technologies

TSV (Through-Silicon Via) faces challenges such as complex fabrication processes, high cost, and thermal management issues, while Flip Chip technology struggles with fine-pitch interconnect alignment and mechanical reliability. Future trends in packaging technologies emphasize heterogeneous integration, advanced materials for improved heat dissipation, and scalable manufacturing processes to enhance device performance and miniaturization. Innovations like 3D stacking and fan-out wafer-level packaging are expected to complement or replace traditional TSV and Flip Chip methods, addressing their limitations in next-generation electronics.

Conclusion: Selecting the Right Technology

TSV (Through-Silicon Via) offers superior vertical interconnect density and is ideal for high-performance applications requiring compact 3D integration, while Flip Chip excels in cost-effective, high-yield 2D assembly with excellent thermal management. Your choice depends on balancing device complexity, cost constraints, and performance needs, with TSV suited for advanced, miniaturized systems and Flip Chip favored in mass production scenarios. Evaluating these factors ensures selecting the technology that optimally supports your product's functionality and market demands.

TSV vs Flip Chip Infographic

libmatt.com

libmatt.com