Si (silicon) offers excellent electrical properties and thermal stability, making it the standard material for most semiconductor devices. SiGe (silicon-germanium) enhances performance by providing higher electron mobility and faster transistor switching speeds, benefiting your high-frequency and high-speed integrated circuits.

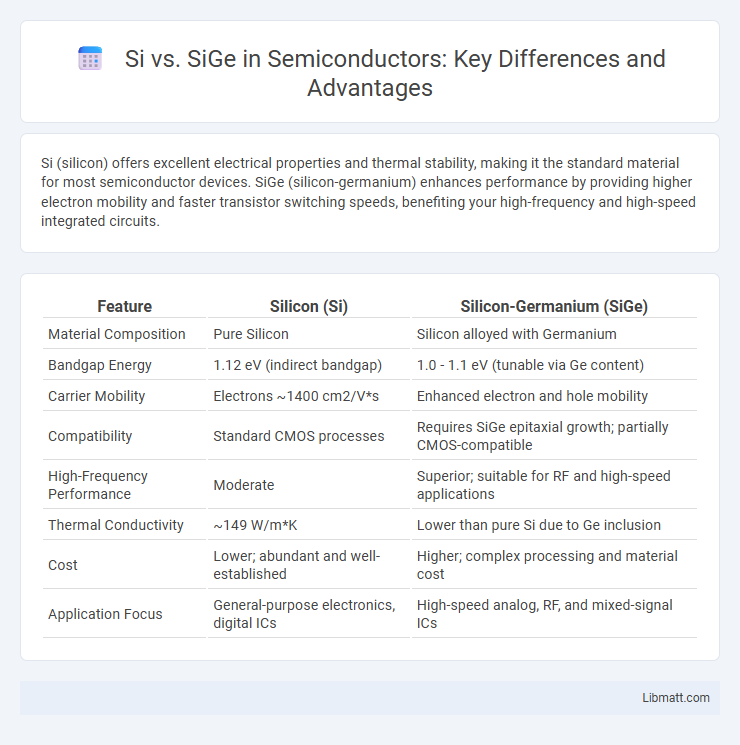

Table of Comparison

| Feature | Silicon (Si) | Silicon-Germanium (SiGe) |

|---|---|---|

| Material Composition | Pure Silicon | Silicon alloyed with Germanium |

| Bandgap Energy | 1.12 eV (indirect bandgap) | 1.0 - 1.1 eV (tunable via Ge content) |

| Carrier Mobility | Electrons ~1400 cm2/V*s | Enhanced electron and hole mobility |

| Compatibility | Standard CMOS processes | Requires SiGe epitaxial growth; partially CMOS-compatible |

| High-Frequency Performance | Moderate | Superior; suitable for RF and high-speed applications |

| Thermal Conductivity | ~149 W/m*K | Lower than pure Si due to Ge inclusion |

| Cost | Lower; abundant and well-established | Higher; complex processing and material cost |

| Application Focus | General-purpose electronics, digital ICs | High-speed analog, RF, and mixed-signal ICs |

Introduction to Si and SiGe

Silicon (Si) is a widely used semiconductor material known for its excellent electrical properties and abundance, forming the backbone of modern electronic devices. Silicon-Germanium (SiGe) is an alloy combining silicon and germanium, engineered to enhance carrier mobility and improve high-frequency performance in semiconductor applications. SiGe technology offers advantages in speed, power efficiency, and integration, making it a key material for advanced integrated circuits and radio-frequency devices.

Material Properties Comparison

Silicon (Si) exhibits a well-established crystalline structure with moderate electron mobility around 1400 cm2/V*s, whereas silicon-germanium (SiGe) alloys introduce strain in the lattice, enhancing electron mobility up to 1900 cm2/V*s depending on Ge concentration. SiGe offers a tunable bandgap between 1.1 eV (Si) and 0.67 eV (Ge), allowing for improved high-speed device performance and lower power consumption. Thermal conductivity for Si is approximately 150 W/m*K, higher than SiGe alloys which typically range from 70 to 120 W/m*K, affecting heat dissipation in integrated circuits.

Electronic Band Structure Differences

Silicon (Si) exhibits an indirect bandgap with a conduction band minimum located near the X point in the Brillouin zone, resulting in lower electron mobility compared to direct bandgap materials. Silicon-Germanium (SiGe) introduces strain and alloying effects that modify the band structure, reducing the bandgap and shifting conduction band valleys closer to the G point, which enhances carrier mobility. The incorporation of Ge atoms in the Si lattice creates bandgap narrowing and alters effective mass, improving performance in high-speed electronic and optoelectronic devices.

Carrier Mobility in Si vs SiGe

Carrier mobility in SiGe significantly surpasses that in pure silicon due to the strain-induced band structure modification in the SiGe alloy, enhancing electron and hole transport properties. The incorporation of germanium in SiGe lowers the effective mass of carriers and reduces scattering, resulting in higher electron mobility up to 1.5 times greater than in conventional silicon. Optimizing your semiconductor devices with SiGe can lead to improved high-speed performance and lower power consumption compared to standard silicon-based technology.

Applications in Semiconductor Devices

Silicon (Si) is the foundational material for most semiconductor devices due to its excellent native oxide and well-established manufacturing processes. Silicon-Germanium (SiGe) alloys enhance device performance in high-speed and radio-frequency applications by offering higher electron mobility and improved strain engineering. Your choice between Si and SiGe depends on the specific requirements for speed, power efficiency, and integration in advanced semiconductor devices such as transistors and integrated circuits.

Fabrication Techniques and Challenges

Silicon (Si) fabrication relies on mature CMOS technologies with well-established processes such as thermal oxidation and ion implantation, whereas Silicon-Germanium (SiGe) fabrication requires advanced epitaxial growth techniques like chemical vapor deposition (CVD) to form SiGe heterostructures with precise germanium content. Challenges in SiGe fabrication include controlling strain and defects to maintain interface quality, as misfit dislocations can degrade device performance and yield. Additionally, integrating SiGe layers into standard Si processes demands careful thermal budget management to prevent diffusion and maintain sharp doping profiles.

Performance in CMOS Technology

SiGe offers enhanced carrier mobility and strain engineering benefits compared to pure Si, resulting in faster transistor switching speeds and improved drive current in CMOS technology. The heterojunction formed between Si and SiGe layers reduces short-channel effects and leakage currents, contributing to better device scalability for advanced nodes. SiGe's tunable bandgap and higher hole mobility make it particularly advantageous for p-type MOSFETs, boosting overall CMOS performance and power efficiency in high-speed applications.

Thermal Conductivity and Reliability

Silicon (Si) offers higher thermal conductivity compared to Silicon-Germanium (SiGe), facilitating better heat dissipation in high-power applications. SiGe, while having lower thermal conductivity, provides enhanced strain engineering possibilities that can improve device performance but may impact long-term reliability under thermal stress. Your choice between Si and SiGe should balance thermal management needs with reliability requirements for optimal device operation.

Cost and Scalability Factors

Silicon (Si) technology benefits from mature manufacturing processes, resulting in lower production costs and greater scalability for mass-market applications compared to silicon-germanium (SiGe). SiGe offers enhanced performance in high-frequency and high-speed devices but involves more complex and costly epitaxial growth techniques, limiting large-scale deployment. Your choice between Si and SiGe should weigh the trade-offs between cost efficiency and performance requirements for scalable semiconductor solutions.

Future Trends in Si and SiGe Integration

SiGe technology is advancing as a key enabler for high-speed, low-power semiconductor devices, outperforming traditional Si in RF and analog applications due to its higher electron mobility and tunable bandgap. Future trends emphasize heterogeneous integration of SiGe with Si to leverage cost efficiency and superior performance, particularly in 5G, automotive, and IoT applications. Emerging techniques such as molecular beam epitaxy and selective epitaxy promote scalable fabrication, enabling complex Si/SiGe heterostructures for next-generation integrated circuits.

Si vs SiGe Infographic

libmatt.com

libmatt.com