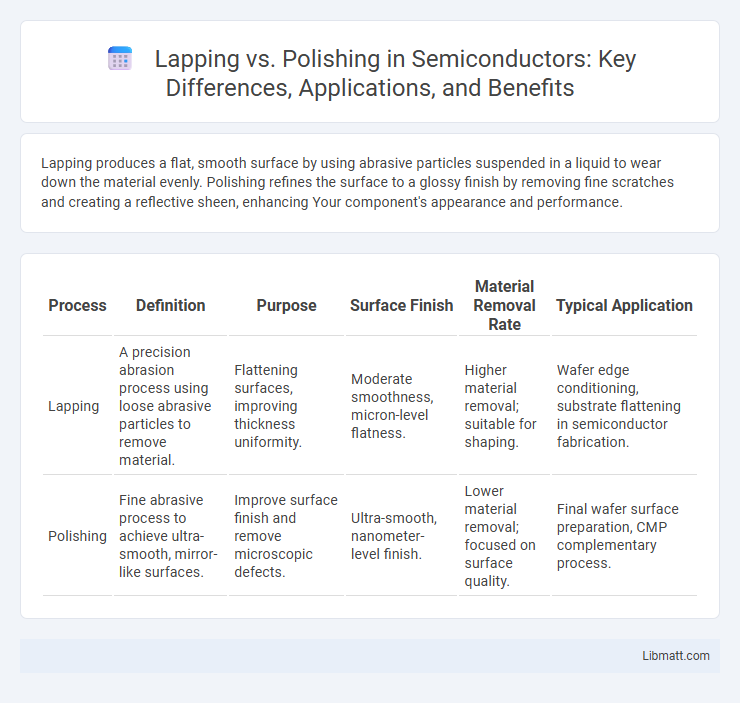

Lapping produces a flat, smooth surface by using abrasive particles suspended in a liquid to wear down the material evenly. Polishing refines the surface to a glossy finish by removing fine scratches and creating a reflective sheen, enhancing Your component's appearance and performance.

Table of Comparison

| Process | Definition | Purpose | Surface Finish | Material Removal Rate | Typical Application |

|---|---|---|---|---|---|

| Lapping | A precision abrasion process using loose abrasive particles to remove material. | Flattening surfaces, improving thickness uniformity. | Moderate smoothness, micron-level flatness. | Higher material removal; suitable for shaping. | Wafer edge conditioning, substrate flattening in semiconductor fabrication. |

| Polishing | Fine abrasive process to achieve ultra-smooth, mirror-like surfaces. | Improve surface finish and remove microscopic defects. | Ultra-smooth, nanometer-level finish. | Lower material removal; focused on surface quality. | Final wafer surface preparation, CMP complementary process. |

Introduction to Lapping and Polishing

Lapping and polishing are precision surface finishing processes used to improve the flatness, smoothness, and optical quality of materials such as metals, ceramics, and glass. Lapping employs abrasive particles suspended in a liquid to wear down surface irregularities through a controlled, mechanical rubbing action, creating a highly uniform and flat surface. Polishing refines this surface further by removing microscopic scratches and enhancing gloss, often using finer abrasives or chemical agents to achieve mirror-like finishes critical for optical and industrial applications.

Key Differences Between Lapping and Polishing

Lapping involves abrasive particles suspended in a liquid used with a rigid plate to achieve precise flatness and dimensional accuracy, while polishing employs finer abrasives or chemical agents to enhance surface smoothness and gloss. Lapping typically removes material uniformly to correct flatness and thickness, whereas polishing aims to reduce surface roughness for improved aesthetic and functional qualities. The main difference lies in lapping's focus on geometric precision versus polishing's emphasis on surface finish and appearance.

Overview of the Lapping Process

Lapping is a precision machining process used to achieve extremely flat, smooth surfaces by rubbing two surfaces together with an abrasive slurry between them. It involves a controlled, slow-speed rotation of a lapping plate and the workpiece, ensuring uniform material removal and minimal surface distortion. This method is essential in industries requiring high dimensional accuracy and superior surface finishes, such as semiconductor manufacturing, optics, and aerospace component production.

Understanding the Polishing Process

The polishing process involves using fine abrasive materials to create a smooth, reflective surface by removing microscopic peaks and imperfections. Unlike lapping, which primarily focuses on flattening and dimensional accuracy, polishing enhances surface finish and optical clarity. Understanding polishing helps you achieve precise surface quality critical in industries like electronics, optics, and automotive manufacturing.

Surface Finishes: Lapping vs Polishing

Lapping produces ultra-flat, mirror-like surface finishes by removing material through abrasive slurry and a rotating plate, achieving tolerances in the micron or sub-micron range. Polishing smooths surfaces by gradually abrading imperfections, enhancing gloss and texture without the extreme flatness achieved by lapping, making it ideal for aesthetic or minor surface improvements. Your choice between lapping and polishing depends on the required surface finish precision and application, with lapping favored for high-precision optical or mechanical parts and polishing for decorative or functional surface enhancement.

Materials Suitable for Lapping vs Polishing

Materials suitable for lapping include hard and brittle substances like ceramics, metals, and glass, as this process removes material through a precise abrasive action designed to achieve flatness and smoothness. Polishing, on the other hand, is ideal for softer materials such as plastics, jewelry metals, and certain alloys where enhancing surface gloss and removing minor scratches is the primary goal. Your choice between lapping and polishing depends on the material's hardness and the desired surface finish quality.

Equipment and Tools Used in Lapping and Polishing

Lapping employs a flat, rigid lap plate combined with abrasive slurry or film for precise material removal and surface flattening. Polishing uses soft cloths or pads with fine abrasive compounds or polishing pastes to achieve smooth, mirror-like finishes on various substrates. Both processes require specific machinery such as lapping machines with controlled pressure and speed, while polishing often utilizes rotary or vibratory polishers for consistent surface quality.

Advantages and Disadvantages of Lapping and Polishing

Lapping offers exceptional surface flatness and precision, making it ideal for applications requiring tight tolerances, but it is time-consuming and may cause material removal inconsistencies. Polishing enhances surface smoothness and aesthetics with faster processing times, yet it may not achieve the same level of flatness or dimensional accuracy as lapping. Understanding your specific surface finish and precision needs will help determine whether lapping or polishing best suits your project goals.

Applications of Lapping and Polishing in Industry

Lapping is primarily used in industries requiring ultra-flat surfaces and tight tolerances, such as semiconductor manufacturing, aerospace components, and precision optical lenses. Polishing finds extensive applications in automotive, jewelry, and medical device industries where surface smoothness and aesthetic finish are critical. Your choice between lapping and polishing depends on the desired surface quality and application-specific requirements.

Choosing the Right Technique: Lapping or Polishing

Choosing between lapping and polishing depends on the desired surface finish and material tolerances. Lapping achieves high precision flatness and uniformity, ideal for applications requiring tight dimensional control and smooth, planar surfaces. Polishing enhances surface gloss and removes minor imperfections, making it suitable for aesthetic finishes and surfaces requiring reduced roughness without extensive material removal.

Lapping vs Polishing Infographic

libmatt.com

libmatt.com