Edge Emitting Lasers (EELs) produce laser light from the edge of the semiconductor chip and are known for higher power output and longer emission wavelengths, making them ideal for applications like fiber-optic communication and materials processing. VCSELs (Vertical-Cavity Surface-Emitting Lasers) emit light perpendicular to the chip surface, offering advantages in manufacturability, lower power consumption, and ease of integration into arrays, often used in data communications, sensing, and consumer electronics.

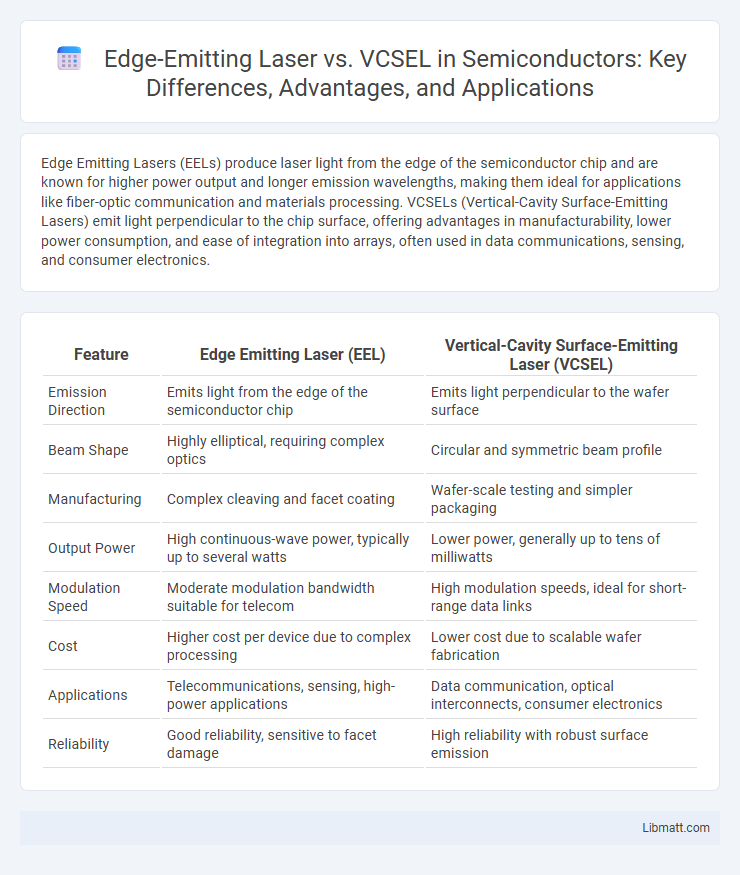

Table of Comparison

| Feature | Edge Emitting Laser (EEL) | Vertical-Cavity Surface-Emitting Laser (VCSEL) |

|---|---|---|

| Emission Direction | Emits light from the edge of the semiconductor chip | Emits light perpendicular to the wafer surface |

| Beam Shape | Highly elliptical, requiring complex optics | Circular and symmetric beam profile |

| Manufacturing | Complex cleaving and facet coating | Wafer-scale testing and simpler packaging |

| Output Power | High continuous-wave power, typically up to several watts | Lower power, generally up to tens of milliwatts |

| Modulation Speed | Moderate modulation bandwidth suitable for telecom | High modulation speeds, ideal for short-range data links |

| Cost | Higher cost per device due to complex processing | Lower cost due to scalable wafer fabrication |

| Applications | Telecommunications, sensing, high-power applications | Data communication, optical interconnects, consumer electronics |

| Reliability | Good reliability, sensitive to facet damage | High reliability with robust surface emission |

Introduction to Edge Emitting Lasers and VCSELs

Edge Emitting Lasers (EELs) emit light from the edge of the semiconductor chip, producing high power and narrow beam divergence ideal for long-distance optical communication. Vertical Cavity Surface Emitting Lasers (VCSELs) emit light perpendicular to the chip surface, offering lower power consumption and easier testing for high-density data centers and short-reach applications. Your choice between EELs and VCSELs depends on factors like required power, beam quality, and application distance.

Operating Principles of Edge Emitting Lasers

Edge Emitting Lasers (EELs) generate light by amplifying photons within a semiconductor gain medium, emitting the laser beam from the edge of the chip. This lateral emission results from carrier injection and stimulated emission along the waveguide, producing high output power and narrow spectral width. Your choice of EELs benefits applications requiring long-distance communication and precise beam control due to their directional and efficient operating principles.

Operating Principles of VCSELs

Vertical-Cavity Surface-Emitting Lasers (VCSELs) operate by emitting light perpendicular to the surface of the semiconductor chip, utilizing multiple quantum well structures between two distributed Bragg reflector (DBR) mirrors for optical feedback. This design enables lower threshold currents and high-speed modulation compared to Edge Emitting Lasers (EELs), which emit light from the side of the chip through a cleaved facet. Your choice of a VCSEL can benefit applications requiring efficient, wafer-scale testing and precise beam circularity.

Structural Differences: Edge Emitters vs VCSELs

Edge Emitting Lasers (EELs) feature a lateral emission structure where the light exits from the edge of the semiconductor chip, utilizing multiple quantum wells aligned parallel to the surface. Vertical Cavity Surface Emitting Lasers (VCSELs) emit light perpendicularly from the chip surface, incorporating a shorter cavity with distributed Bragg reflector (DBR) mirrors above and below the active region. The fundamental structural difference between EELs and VCSELs lies in their cavity orientation and emission direction, significantly influencing their optical properties and integration capabilities.

Performance Comparison: Output Power and Efficiency

Edge Emitting Lasers (EELs) deliver higher output power levels, often reaching several watts, making them ideal for applications requiring strong, focused beams. Vertical-Cavity Surface-Emitting Lasers (VCSELs) offer superior energy efficiency with lower threshold currents and better thermal management, resulting in less power consumption. While EELs excel in high-power performance, VCSELs provide greater efficiency and scalability for compact, low-power devices.

Beam Quality and Divergence

Edge Emitting Lasers (EELs) typically exhibit higher beam quality with a narrower divergence angle due to their elongated cavity structure, making them suitable for applications requiring precise, long-distance light delivery. Vertical-Cavity Surface-Emitting Lasers (VCSELs) emit beams with a circular profile but generally have higher divergence, resulting in lower beam quality compared to EELs. Understanding these differences can help you select the optimal laser type based on your application's beam shaping and focusing requirements.

Modulation Speed and Data Transmission

Edge Emitting Lasers (EELs) typically achieve higher modulation speeds exceeding 10 GHz, making them suitable for long-haul and high-capacity data transmission in fiber-optic networks. Vertical-Cavity Surface-Emitting Lasers (VCSELs) offer modulation speeds up to around 30 GHz in advanced designs and excel in short-reach, high-density data communication links due to their lower cost and ease of integration in arrays. Key parameters influencing data transmission include the modulation bandwidth, threshold current, and thermal management capabilities of both EELs and VCSELs.

Applications in Modern Technologies

Edge Emitting Lasers (EELs) are widely used in high-speed fiber optic communications, industrial machining, and medical devices due to their high power output and narrow beam profile. Vertical-Cavity Surface-Emitting Lasers (VCSELs) excel in data centers, 3D sensing, and LiDAR systems for autonomous vehicles because of their low power consumption, compact size, and ease of integration into arrays. Your choice between EEL and VCSEL will depend on the application's power requirements, wavelength stability, and spatial coherence needs.

Reliability and Manufacturing Challenges

Edge Emitting Lasers (EELs) exhibit superior reliability in high-power applications due to their well-established thermal management and robust cavity design, while Vertical-Cavity Surface-Emitting Lasers (VCSELs) face challenges related to multi-mode emission and packaging. VCSELs benefit from simpler wafer-level testing and lower production costs, but their reliability can be compromised by smaller active regions and sensitivity to manufacturing variations. Manufacturing challenges for EELs include complex facet processing and alignment, whereas VCSELs require precise control of Distributed Bragg Reflectors (DBRs) and current confinement structures.

Future Trends in Laser Technology

Future trends in laser technology emphasize the increasing adoption of VCSELs (Vertical-Cavity Surface-Emitting Lasers) due to their scalability, lower manufacturing costs, and superior energy efficiency compared to traditional Edge Emitting Lasers (EELs). Research in high-power VCSEL arrays aims to enhance beam quality and output power, enabling applications in LiDAR, optical communications, and 3D sensing. Despite advancements, EELs remain crucial for specific high-power and long-distance applications, ensuring a complementary evolution in laser technology.

Edge Emitting Laser vs VCSEL Infographic

libmatt.com

libmatt.com