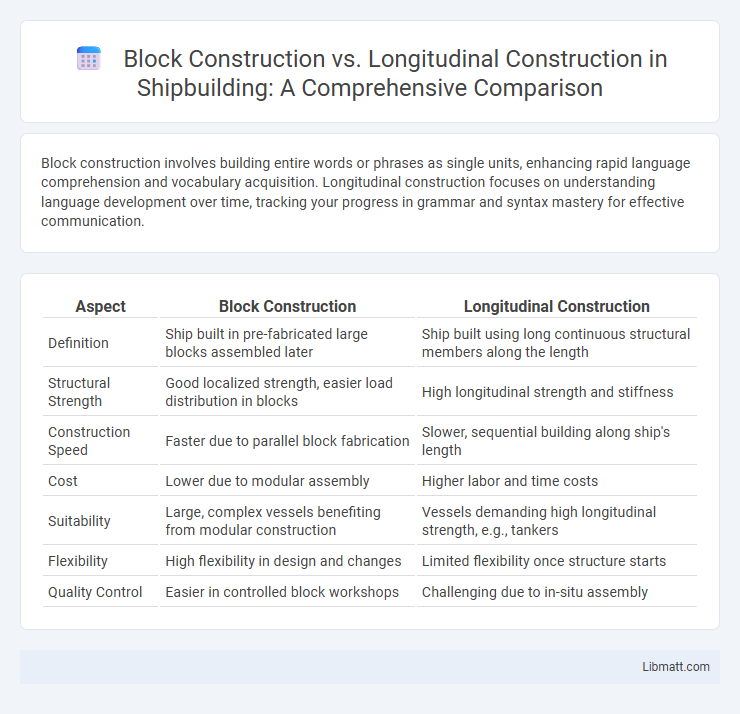

Block construction involves building entire words or phrases as single units, enhancing rapid language comprehension and vocabulary acquisition. Longitudinal construction focuses on understanding language development over time, tracking your progress in grammar and syntax mastery for effective communication.

Table of Comparison

| Aspect | Block Construction | Longitudinal Construction |

|---|---|---|

| Definition | Ship built in pre-fabricated large blocks assembled later | Ship built using long continuous structural members along the length |

| Structural Strength | Good localized strength, easier load distribution in blocks | High longitudinal strength and stiffness |

| Construction Speed | Faster due to parallel block fabrication | Slower, sequential building along ship's length |

| Cost | Lower due to modular assembly | Higher labor and time costs |

| Suitability | Large, complex vessels benefiting from modular construction | Vessels demanding high longitudinal strength, e.g., tankers |

| Flexibility | High flexibility in design and changes | Limited flexibility once structure starts |

| Quality Control | Easier in controlled block workshops | Challenging due to in-situ assembly |

Introduction to Block and Longitudinal Construction

Block construction organizes data into fixed-size segments or blocks, facilitating efficient storage, retrieval, and error correction in digital systems. Longitudinal construction arranges data sequentially along a linear axis, optimizing processes like streaming and real-time transmission by maintaining temporal or logical order. Understanding these construction methods enhances system design by balancing access speed, data integrity, and application-specific requirements.

Defining Block Construction

Block construction refers to a building technique where structures are assembled using pre-formed, modular blocks, typically made from concrete or similar materials, allowing for rapid and uniform construction. This method emphasizes the stacking of individual block units with mortar to create walls or foundations, promoting strength and thermal insulation. It contrasts with longitudinal construction, which organizes structural elements predominantly along a linear, lengthwise axis, affecting load distribution and architectural design.

Understanding Longitudinal Construction

Longitudinal construction involves assembling a structure by aligning and joining components along its length, optimizing stability and load distribution. This method enhances seamless integration of sequential parts, ensuring efficient stress management and reducing material fatigue. Compared to block construction, longitudinal construction allows for streamlined assembly and improved structural coherence in projects such as bridges, pipelines, and ships.

Key Differences Between Block and Longitudinal Methods

Block construction assembles prefabricated sections or modules to form a complete structure, emphasizing rapid on-site assembly and uniform quality control. Longitudinal construction builds the project sequentially along a linear path, commonly used in infrastructure like roads and pipelines, allowing continuous progress and efficient resource allocation. Your choice depends on project scale and site conditions, as block methods suit modular buildings, while longitudinal suits extended linear developments.

Structural Integrity: Block vs Longitudinal Approaches

Block construction offers enhanced structural integrity by providing uniform strength distribution across the entire component, reducing stress concentrations. Longitudinal construction aligns material fibers or reinforcements along the length, optimizing load-bearing capacity in specific directions but potentially creating weaker points across the transverse axis. Understanding these differences helps you select the ideal method based on the structural demands of your project.

Material Usage and Efficiency

Block construction typically uses prefabricated modules made of concrete or steel, optimizing material consistency and reducing waste. Longitudinal construction employs continuous materials such as steel or timber beams, which can lead to more efficient load distribution but may require more precise material sizing. Both methods influence material efficiency differently; block construction allows faster assembly with standardized parts, while longitudinal construction offers adaptability in material length and structural design.

Application Areas in Modern Construction

Block construction excels in residential buildings, schools, and small commercial projects due to its ease of assembly and excellent thermal insulation properties. Longitudinal construction is preferred for large-scale infrastructure like bridges, tunnels, and high-rise buildings, where axial load distribution and structural continuity are critical. Your choice between these methods impacts project scalability, durability, and performance in modern construction applications.

Cost Comparison and Budget Considerations

Block construction generally incurs higher initial costs due to extensive material use and labor, whereas longitudinal construction often reduces expenses by simplifying structural elements. Your budget must account for potential variations in durability and maintenance costs, as block structures typically offer better long-term resilience. Evaluating upfront investment alongside lifecycle expenses ensures an informed decision aligned with financial goals.

Durability and Maintenance Factors

Block construction offers superior durability due to its solid, interlocking nature, which resists weathering and structural wear over time better than longitudinal construction. Maintenance demands for block construction are generally lower because the uniform blocks distribute stress evenly, reducing the likelihood of cracks and material degradation. Longitudinal construction, while potentially easier to modify, often requires more frequent inspections and repairs to maintain structural integrity, as its linear components can be more susceptible to uneven pressure and environmental damage.

Choosing the Right Construction Method for Your Project

Block construction offers faster assembly and modular flexibility, ideal for projects requiring efficient timelines and standardized components. Longitudinal construction provides enhanced structural integrity and seamless integration for continuous, elongated structures such as bridges and pipelines. Selecting the right method depends on project scale, complexity, and the desired balance between speed and durability.

Block construction vs longitudinal construction Infographic

libmatt.com

libmatt.com