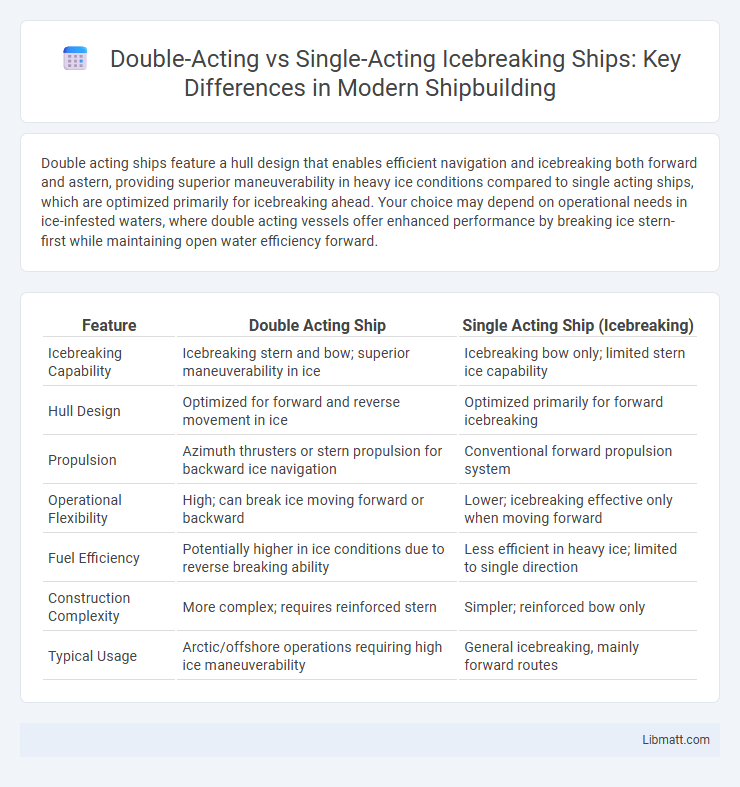

Double acting ships feature a hull design that enables efficient navigation and icebreaking both forward and astern, providing superior maneuverability in heavy ice conditions compared to single acting ships, which are optimized primarily for icebreaking ahead. Your choice may depend on operational needs in ice-infested waters, where double acting vessels offer enhanced performance by breaking ice stern-first while maintaining open water efficiency forward.

Table of Comparison

| Feature | Double Acting Ship | Single Acting Ship (Icebreaking) |

|---|---|---|

| Icebreaking Capability | Icebreaking stern and bow; superior maneuverability in ice | Icebreaking bow only; limited stern ice capability |

| Hull Design | Optimized for forward and reverse movement in ice | Optimized primarily for forward icebreaking |

| Propulsion | Azimuth thrusters or stern propulsion for backward ice navigation | Conventional forward propulsion system |

| Operational Flexibility | High; can break ice moving forward or backward | Lower; icebreaking effective only when moving forward |

| Fuel Efficiency | Potentially higher in ice conditions due to reverse breaking ability | Less efficient in heavy ice; limited to single direction |

| Construction Complexity | More complex; requires reinforced stern | Simpler; reinforced bow only |

| Typical Usage | Arctic/offshore operations requiring high ice maneuverability | General icebreaking, mainly forward routes |

Introduction to Icebreaking Ships

Icebreaking ships are specialized vessels designed to navigate through ice-covered waters by breaking and clearing ice to create a safe passage. Single acting icebreakers operate conventionally forward in open water and break ice by moving bow-first, whereas double acting ships use a novel concept where the vessel advances bow-first in open water and astern in heavy ice conditions, utilizing an optimized stern shape for icebreaking. The double acting ship concept enhances icebreaking efficiency and maneuverability in extreme polar environments, often incorporating advanced propulsion systems like azimuth thrusters for superior control.

Overview of Single Acting Icebreaking Ships

Single acting icebreaking ships feature a conventional bow designed primarily for open water navigation, optimized for forward icebreaking through thick, level ice. These vessels often struggle with heavy ice conditions when moving astern, limiting their operational flexibility in harsh ice environments. Their hull form and propulsion systems focus on maximizing performance in one direction, which contrasts with double acting ships that are equally capable moving both forward and backward in ice.

Overview of Double Acting Icebreaking Ships

Double acting icebreaking ships are designed to navigate challenging polar waters by operating efficiently both forward and astern, with a bow optimized for open water performance and a stern reinforced for icebreaking. These vessels utilize advanced propulsion systems, often Azipods, enabling superior maneuverability and broken ice propulsion when moving backward, which enhances safety and operational efficiency in thick ice conditions. Compared to single acting ships that break ice only moving forward, double acting ships provide greater versatility and reliability in ice-covered seas, making them ideal for year-round Arctic operations.

Key Design Differences

Double acting ships feature reinforced hulls at both the bow and stern, enabling effective icebreaking by navigating forward in open water and astern in heavy ice conditions, unlike single acting ships which are designed primarily for forward icebreaking with reinforced bows only. The propulsion system in double acting ships is typically azimuth thrusters or podded propulsors, providing enhanced maneuverability and the ability to break ice while moving astern, whereas single acting ships generally use fixed propellers optimized for forward movement. Structural design of double acting vessels includes optimized stern shapes and ice-strengthened stern regions to withstand ice loads, contrasting with the focus on bow hull strength and ice belt reinforcement in single acting vessels.

Propulsion Systems Comparison

Double acting ships feature advanced propulsion systems with azimuth thrusters or podded propellers that enable enhanced maneuverability and efficient icebreaking by allowing the vessel to sail stern-first in thick ice. Single acting ships typically use conventional fixed propellers optimized for forward navigation, which limits their icebreaking capability and maneuverability compared to double acting designs. Your choice between these vessels depends on the need for superior ice performance and operational flexibility, where double acting ships provide significant advantages in propulsion efficiency and directional control.

Icebreaking Performance: Efficiency and Capability

Double acting ships excel in icebreaking performance by breaking ice both forward and aft, improving efficiency in harsh Arctic conditions compared to single acting ships, which break ice primarily while moving forward. The dual-directional capability allows double acting vessels to navigate thicker ice and reduce resistance, enhancing fuel efficiency and operational capability. Your choice of vessel can significantly impact ice navigation efficiency, with double acting ships offering superior maneuverability and adaptability in challenging ice-covered waters.

Operational Flexibility and Versatility

Double acting ships offer enhanced operational flexibility and versatility by navigating efficiently in both open water and heavy ice conditions, using a conventional bow in open water and an icebreaking stern for maneuvering through ice. Single acting ships are primarily designed to break ice when moving forward, limiting their performance to icebreaking in one direction, which restricts their operational range in varying ice conditions. The ability of double acting ships to switch directions without assistance improves route options and reduces transit time in polar shipping routes.

Fuel Consumption and Environmental Impact

Double acting ships optimize fuel consumption by navigating forwards in open water and backwards in ice, reducing resistance and engine load, which lowers emissions compared to single acting ships designed for forward icebreaking only. Your operations benefit environmentally as double acting vessels produce fewer greenhouse gases due to improved efficiency in harsh ice conditions. Single acting ships often consume more fuel as their hull design increases resistance in ice, contributing to higher environmental impact during icebreaking voyages.

Cost Implications: Construction and Maintenance

Double acting ships feature advanced hull designs and specialized propulsion systems, resulting in higher initial construction costs compared to single acting ships. Maintenance expenses for double acting ships can also be elevated due to the complexity of their icebreaking propulsion units and the need for specialized repairs. Single acting ships typically incur lower construction and maintenance costs but may face operational limitations in severe ice conditions, impacting overall cost-effectiveness.

Future Trends in Icebreaking Ship Technology

Future trends in icebreaking ship technology emphasize the growing adoption of double acting ships (DAS) due to their enhanced maneuverability and efficiency in harsh ice conditions compared to single acting ships (SAS). Double acting ships utilize advanced propulsion systems, such as azimuth thrusters, enabling them to operate stern-first in heavy ice while maintaining optimal open-water performance, driving energy savings and reducing emissions. Continued innovations in hull design, ice navigation technologies, and hybrid power integration further position double acting ships as the preferred choice for sustainable Arctic and Antarctic operations.

Double acting ship vs single acting ship (icebreaking) Infographic

libmatt.com

libmatt.com