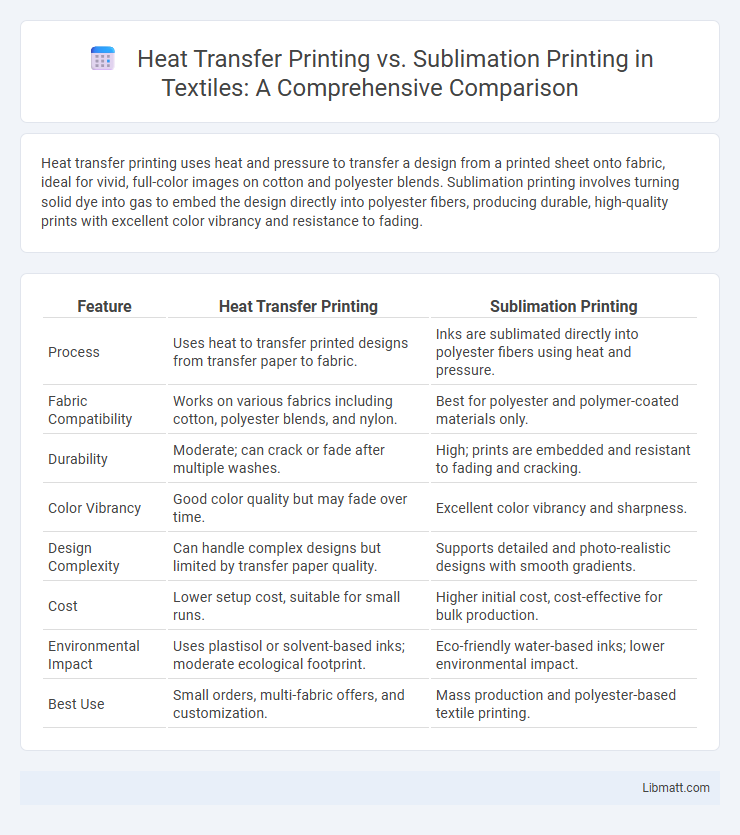

Heat transfer printing uses heat and pressure to transfer a design from a printed sheet onto fabric, ideal for vivid, full-color images on cotton and polyester blends. Sublimation printing involves turning solid dye into gas to embed the design directly into polyester fibers, producing durable, high-quality prints with excellent color vibrancy and resistance to fading.

Table of Comparison

| Feature | Heat Transfer Printing | Sublimation Printing |

|---|---|---|

| Process | Uses heat to transfer printed designs from transfer paper to fabric. | Inks are sublimated directly into polyester fibers using heat and pressure. |

| Fabric Compatibility | Works on various fabrics including cotton, polyester blends, and nylon. | Best for polyester and polymer-coated materials only. |

| Durability | Moderate; can crack or fade after multiple washes. | High; prints are embedded and resistant to fading and cracking. |

| Color Vibrancy | Good color quality but may fade over time. | Excellent color vibrancy and sharpness. |

| Design Complexity | Can handle complex designs but limited by transfer paper quality. | Supports detailed and photo-realistic designs with smooth gradients. |

| Cost | Lower setup cost, suitable for small runs. | Higher initial cost, cost-effective for bulk production. |

| Environmental Impact | Uses plastisol or solvent-based inks; moderate ecological footprint. | Eco-friendly water-based inks; lower environmental impact. |

| Best Use | Small orders, multi-fabric offers, and customization. | Mass production and polyester-based textile printing. |

Introduction to Heat Transfer and Sublimation Printing

Heat transfer printing uses heat and pressure to transfer a design from a special film onto fabric, enabling vibrant images on a wide range of materials like cotton and polyester blends. Sublimation printing employs a heat press to convert dye into gas, embedding the ink directly into polyester fibers for durable, high-resolution prints that resist fading and cracking. Your choice between heat transfer and sublimation printing depends on fabric type, desired print quality, and longevity requirements.

Understanding Heat Transfer Printing

Heat transfer printing involves applying heat and pressure to transfer a design from a vinyl or transfer paper onto a substrate, often fabrics or hard surfaces. This method allows high precision with vibrant colors and is suitable for short runs or customized apparel. Heat transfer printing excels in producing durable, high-quality images on materials that cannot withstand the high temperatures required for sublimation.

What is Sublimation Printing?

Sublimation printing is a digital printing process where heat transforms solid dye into gas without passing through a liquid phase, embedding the ink directly into polyester or polymer-coated materials. This method produces vibrant, long-lasting images with excellent color accuracy and durability, ideal for fabrics, ceramics, and metals. Sublimation printing is favored for its ability to create detailed, full-color designs that resist fading and cracking over time.

Key Differences Between Heat Transfer and Sublimation Printing

Heat transfer printing uses heat and pressure to transfer pigment-based inks from a carrier sheet onto fabric, making it ideal for cotton and dark materials, while sublimation printing involves converting dye into gas to infuse polyester fibers, producing vibrant, durable designs best suited for light-colored polyester fabrics. Heat transfer prints tend to sit atop the fabric, which may result in a heavier feel and potential cracking over time, whereas sublimation prints become part of the fabric, ensuring a softer texture and high wash durability. The color vibrancy and longevity also differ, with sublimation offering more vivid colors and resistance to fading compared to the heat transfer method.

Pros and Cons of Heat Transfer Printing

Heat transfer printing offers vibrant color reproduction and is cost-effective for small runs, making it ideal for custom apparel and promotional items. However, it may result in a heavier, less breathable print and shows signs of cracking or peeling after frequent washes. This method supports a wide range of fabric types but lacks the durability and softness that sublimation printing provides on polyester materials.

Pros and Cons of Sublimation Printing

Sublimation printing offers vibrant, durable colors that penetrate fabric fibers, making it ideal for polyester and polyester-blend materials with excellent fade resistance and washability. However, its limitations include poor results on dark or natural fabrics and higher initial equipment costs compared to heat transfer printing. Your choice should consider fabric compatibility and long-term use to maximize the advantages of sublimation printing.

Material Compatibility: What Works Best?

Heat transfer printing works best on cotton, polyester blends, and darker fabrics due to its ability to adhere through heat-applied adhesives, while sublimation printing is ideal for polyester or polymer-coated materials, as the dye bonds with synthetic fibers for vibrant, long-lasting results. If your project involves natural fibers like cotton, heat transfer provides better color saturation and durability, whereas sublimation excels on light-colored polyester fabrics, offering a softer feel and higher detail. Your choice depends on the fabric type and desired print quality, with sublimation preferred for synthetic textiles and heat transfer suited for a broader range of materials.

Print Quality and Durability Comparison

Heat transfer printing offers vibrant colors and sharp details but can sometimes result in a heavier feel and slight cracking over time, especially with frequent washing. Sublimation printing embeds ink directly into polyester fibers, producing high-resolution, durable prints that resist fading, peeling, and cracking, ideal for long-lasting designs. For your apparel or promotional items, sublimation ensures superior print quality and durability, especially on polyester fabrics, compared to heat transfer methods.

Cost Analysis: Heat Transfer vs Sublimation Printing

Heat transfer printing typically incurs lower upfront costs due to affordable equipment and versatile material compatibility, making it suitable for small batch production and varied substrates. Sublimation printing involves higher initial investment in specialized printers and inks but delivers cost efficiency in large volume runs and produces vibrant, durable prints on polyester fabrics. Overall, heat transfer is cost-effective for limited quantities, while sublimation offers better long-term value for high-volume, polyester-based products.

Choosing the Right Printing Method for Your Needs

Heat transfer printing offers versatility on various fabric types and is cost-effective for small runs, making it ideal for customized apparel and detailed designs. Sublimation printing excels on polyester materials by infusing dye directly into the fabric, providing vibrant colors and long-lasting durability for high-quality, full-color images. Selecting the right printing method depends on fabric compatibility, design complexity, color vibrancy requirements, and production volume to ensure optimal results and cost efficiency.

Heat Transfer Printing vs Sublimation Printing Infographic

libmatt.com

libmatt.com